- Forums

- Tools, Compressors and Metal Coatings

- Tools, Materials and Techniques

- Machining

- Lathes and other Machining Equipment

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

REBUILD: Lorch plain-turning lathe

- Thread starter daxliniere

- Start date

daxliniere

Member

- Messages

- 174

- Location

- North London, UK

Yep, that's what I ended up doing. The rod is dead-straight, but I did find the problem and was able to fix it.If you can't see it wobble it's not bent enough to cause an issue. I would have suggested laying it flat along the bed (without its nut) would also work.

It was rubbing on the bore that it sleeves into (a straight bore with larger ID than the lead screw's OD, "behind" the brass fixed nut). There was the slightest of bend in the cross slide plate, I could see a sliver of light under the middle of a straight edge held across the top surface. Not exactly sure how it would have happened, perhaps overtightening of the bolt that threads into the T-nut. Either way, a little banging with a punch took out about half of the bow. Then I progressively drilled the bore a little larger from the point at which it started to bind. +1mm ø for about 100mm, then 1.5mm ø for the last 20mm.

Now the axis moves really well.

I'm still working on getting the gibs right, trying to balance out stiffness against play.

I'm still working on getting the gibs right, trying to balance out stiffness against play.I've also discovered that the tailstock and spindle centres aren't aligned, by quite a lot. Probably 1.5-2mm. The first thing I'm going to check is that the headstock (which is held by a single bolt (why???)) is parallel to the ways.

daxliniere

Member

- Messages

- 174

- Location

- North London, UK

Hey gang! I finally got a bit of time to finish off a few more things on the lathe and I'm pretty happy with how it turned out. I made a little video showing the upgrades:

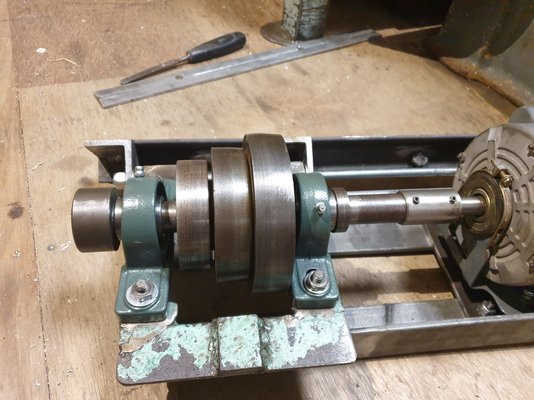

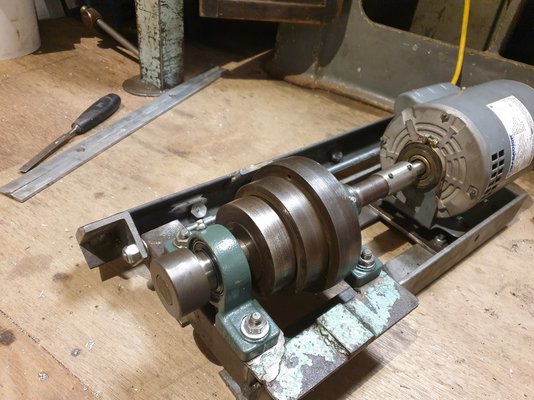

-Belt cover with hinges for access plus shelf for storage

-Lorch logo plate

-Z-carriage lock

-Tool post wrench

-Pillow block bearings for motor pulleys

-An innovative power switch

https://youtu.be/7nlZXjwBG0c

A huge thank you to everyone who's offered advice here on the forum!!

-Belt cover with hinges for access plus shelf for storage

-Lorch logo plate

-Z-carriage lock

-Tool post wrench

-Pillow block bearings for motor pulleys

-An innovative power switch

https://youtu.be/7nlZXjwBG0c

A huge thank you to everyone who's offered advice here on the forum!!

h-dom

Member

- Messages

- 594

- Location

- Lincs

Great video, love the starter switch, great idea. You wouldn't be the first person to leave the chuck key in the chuck and power it up. Don't ask my hand how I know.

Tidy job on the rest of it, little things that I found annoying with mine like having to get a spanner on the nut under the bed locking the carriage in place, you've solved that, nicely done.

Tidy job on the rest of it, little things that I found annoying with mine like having to get a spanner on the nut under the bed locking the carriage in place, you've solved that, nicely done.

daxliniere

Member

- Messages

- 174

- Location

- North London, UK

daxliniere

Member

- Messages

- 174

- Location

- North London, UK

Barking Mat

Cuddler of hedgehogs.

- Messages

- 13,480

- Location

- France, Brittany.

Nice work.

daxliniere

Member

- Messages

- 174

- Location

- North London, UK

I turned some material using a collet for the first time today and, oh my god, it's so good! In addition to concentricity and general ease of work-holding, the cutting was so much faster. 2.5mm hole down the centre of a long M6 bolt. Such a nice result for a tricky job.

This is to replace a missing spout on my cold saw's coolant system.

This is to replace a missing spout on my cold saw's coolant system.

daxliniere

Member

- Messages

- 174

- Location

- North London, UK

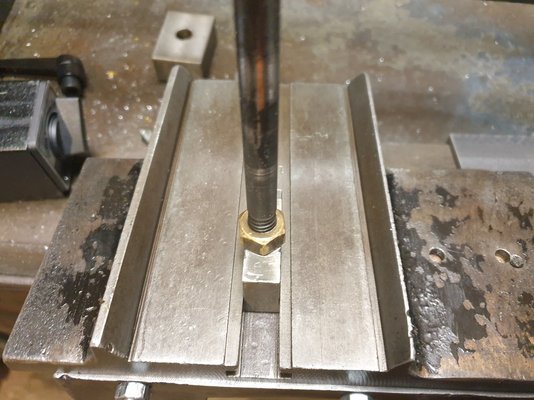

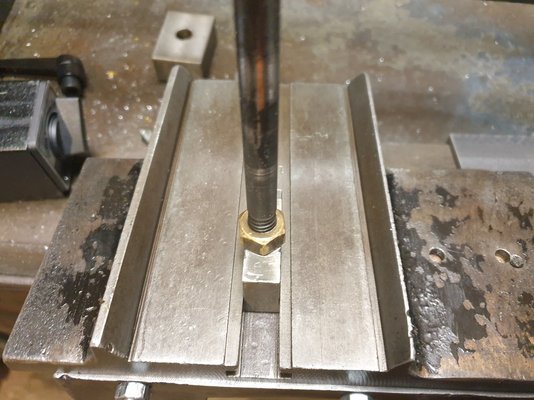

I discovered the source of my spindle-tailstock concentricity problem...

There's a ~1mm gap between the top of the front way and the bit what goes on it ( carriage?) so when I tighten the clamp to hold it in place (it's manual, not on a lead screw), it bends the ways.

The effect is so bad, I measured 4.25mm travel at the crossslide handle!!

Not sure why this is the case, since nothing looks worn or damaged, and the ways are basically parallel along their length, but I think the solution is to add a 1mm shim. (~10mm wide and 160mm long)

The question is, what material? Brass seems a good choice, but I already have some galvanised steel sheet of a close thickness (1.08mm).

It's not going to be sliding back and forth regularly.

Next is mounting. I figured I could probably just fold up both ends to 90° so it will be pushed sideways when the carriage is slid.

The other option is to make the piece much wider and attach it to the bolt that goes down between the ways to tighten the carriage. (Under the brass nut.)

What are people's thoughts on this?

First photo is clamped, second photo you can see the gap between the prismic front way and the carriage.

There's a ~1mm gap between the top of the front way and the bit what goes on it ( carriage?) so when I tighten the clamp to hold it in place (it's manual, not on a lead screw), it bends the ways.

The effect is so bad, I measured 4.25mm travel at the crossslide handle!!

Not sure why this is the case, since nothing looks worn or damaged, and the ways are basically parallel along their length, but I think the solution is to add a 1mm shim. (~10mm wide and 160mm long)

The question is, what material? Brass seems a good choice, but I already have some galvanised steel sheet of a close thickness (1.08mm).

It's not going to be sliding back and forth regularly.

Next is mounting. I figured I could probably just fold up both ends to 90° so it will be pushed sideways when the carriage is slid.

The other option is to make the piece much wider and attach it to the bolt that goes down between the ways to tighten the carriage. (Under the brass nut.)

What are people's thoughts on this?

First photo is clamped, second photo you can see the gap between the prismic front way and the carriage.

Last edited:

daxliniere

Member

- Messages

- 174

- Location

- North London, UK

Well, I solved the problem above (added a shim plate to the underside of the carriage) and have moved on to other upgrades.

The Z axis has about 0.0012" backlash in the handle and I was thinking that there might be a very easy to take that out. The brass (bronze?) nut that the leadscrew mates with looks a bit like a large key and fits into a very tight 'socket'. I was thinking that I could cut about 4-5mm out of the middle of that nut and place a spring between the two halves to make an anti-backlash nut. I think I might need to take a little off one of the rounded ends to account for the spring's expansion, but I'm only 90% sure of that.

Anyone have any ideas?

Image recycled from an earlier post:

The Z axis has about 0.0012" backlash in the handle and I was thinking that there might be a very easy to take that out. The brass (bronze?) nut that the leadscrew mates with looks a bit like a large key and fits into a very tight 'socket'. I was thinking that I could cut about 4-5mm out of the middle of that nut and place a spring between the two halves to make an anti-backlash nut. I think I might need to take a little off one of the rounded ends to account for the spring's expansion, but I'm only 90% sure of that.

Anyone have any ideas?

Image recycled from an earlier post:

daxliniere

Member

- Messages

- 174

- Location

- North London, UK

Aha! No. I was drifting off to sleep when an idea hit me. Rather than making the nut smaller to fit the spring (which would weaken it), it would be better to open up the 'keyway' slot!I was thinking that I could cut about 4-5mm out of the middle of that nut and place a spring between the two halves to make an anti-backlash nut. I think I might need to take a little off one of the rounded ends to account for the spring's expansion.

Dieselman 63

Forklift Certified

- Messages

- 5,856

- Location

- Wellington, New Zealand

The nut is worn. Time for a new one

Agroshield

Member

- Messages

- 6,249

The Z axis has about 0.0012" backlash in the handle

Could you conform that you have written the correct number there. That is 1.2 thousandths of an inch or 12 ten thousandths. That is very good.

Backlash in lathe screws is not so much a problem as on a mill as on a lathe you are always cutting in one direction so any lash is taken up as the tool touches the work.

daxliniere

Member

- Messages

- 174

- Location

- North London, UK

Perhaps it is, Dieselman. May I borrow your time machine to go back to 1910, please?The nut is worn. Time for a new one

daxliniere

Member

- Messages

- 174

- Location

- North London, UK

You're right, I did mean 12 thou.Could you conform that you have written the correct number there. That is 1.2 thousandths of an inch or 12 ten thousandths. That is very good.

That's a very good point that I hadn't considered. I'm just looking for little ways to make this machine as sweet as possible.Backlash in lathe screws is not so much a problem as on a mill as on a lathe you are always cutting in one direction so any lash is taken up as the tool touches the work.

Dieselman 63

Forklift Certified

- Messages

- 5,856

- Location

- Wellington, New Zealand

Perhaps it is, Dieselman. May I borrow your time machine to go back to 1910, please?

Don’t get salty with me, get machining.

daxliniere

Member

- Messages

- 174

- Location

- North London, UK

Hahaha, too true. It was just the way you said 'time for a new one' like walking to the corner shop.Don’t get salty with me, get machining.

Also, you massively overestimate my machining skills. I'm at the start of that journey (hence my grade of questions).

daxliniere

Member

- Messages

- 174

- Location

- North London, UK

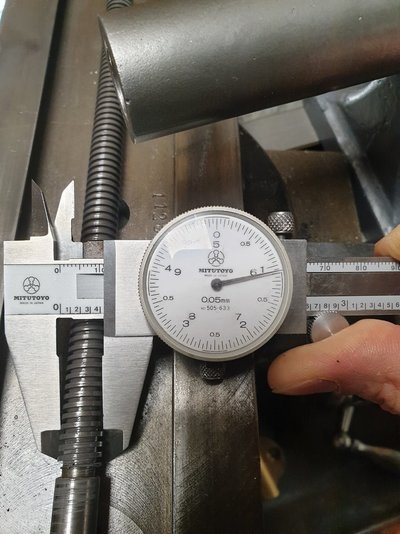

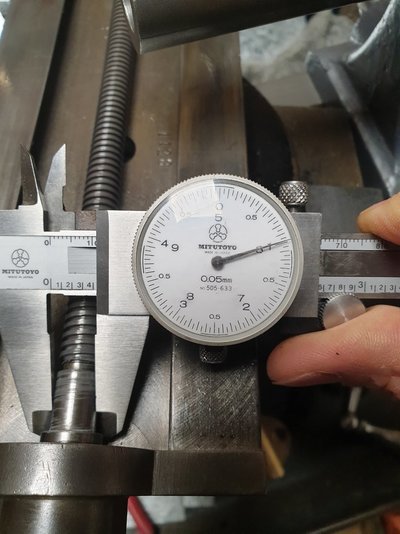

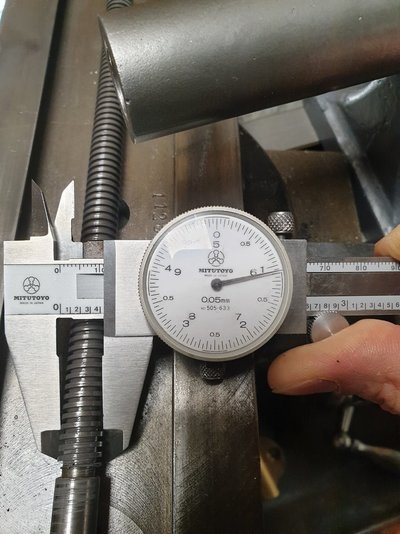

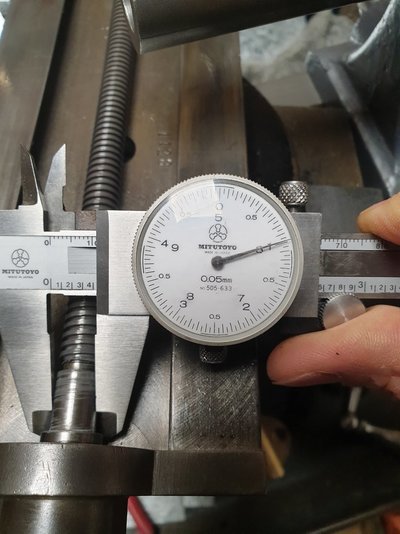

After further investigations, I've learned a few more things about this leadscrew arrangement.

1) It looks to be square thread. 11mm OD, 2.5mm pitch

2) The brass 'keyway' nut is only half-threaded

3) I discovered that one of the 2 holes under the brass nut is threaded, presumably to provide some kind of adjustment, though I can't imagine how pushing it off axis would be a good thing.

I think the solution would be to buy a suitable square thread nut and turn it down to fit inside the unthreaded end of the brass nut, then work out a way to prevent it from spinning.

I can't seem to find much on square thread nuts, but I will be the first to admit it's not something I've ever searched for before. Does anyone have any suggestions?

The bodies in question:

The front side and back side of the nut:

Leadscrew with what looks like square threads:

The curious possible adjustment screw hole:

Bore of the untapped end of the nut:

(some other photos)

1) It looks to be square thread. 11mm OD, 2.5mm pitch

2) The brass 'keyway' nut is only half-threaded

3) I discovered that one of the 2 holes under the brass nut is threaded, presumably to provide some kind of adjustment, though I can't imagine how pushing it off axis would be a good thing.

I think the solution would be to buy a suitable square thread nut and turn it down to fit inside the unthreaded end of the brass nut, then work out a way to prevent it from spinning.

I can't seem to find much on square thread nuts, but I will be the first to admit it's not something I've ever searched for before. Does anyone have any suggestions?

The bodies in question:

The front side and back side of the nut:

Leadscrew with what looks like square threads:

The curious possible adjustment screw hole:

Bore of the untapped end of the nut:

(some other photos)

Last edited: