Hello. Thanks for the replies on m other posts, wish I had something useful to add to somebody else's!

Anyway, I have only been welding a week, I watched a few videos on YouTube then dived straight in. I have a wolf weld 135 MIG. I run it on 'no gas' with the flux cored wire. It is also positive ground.

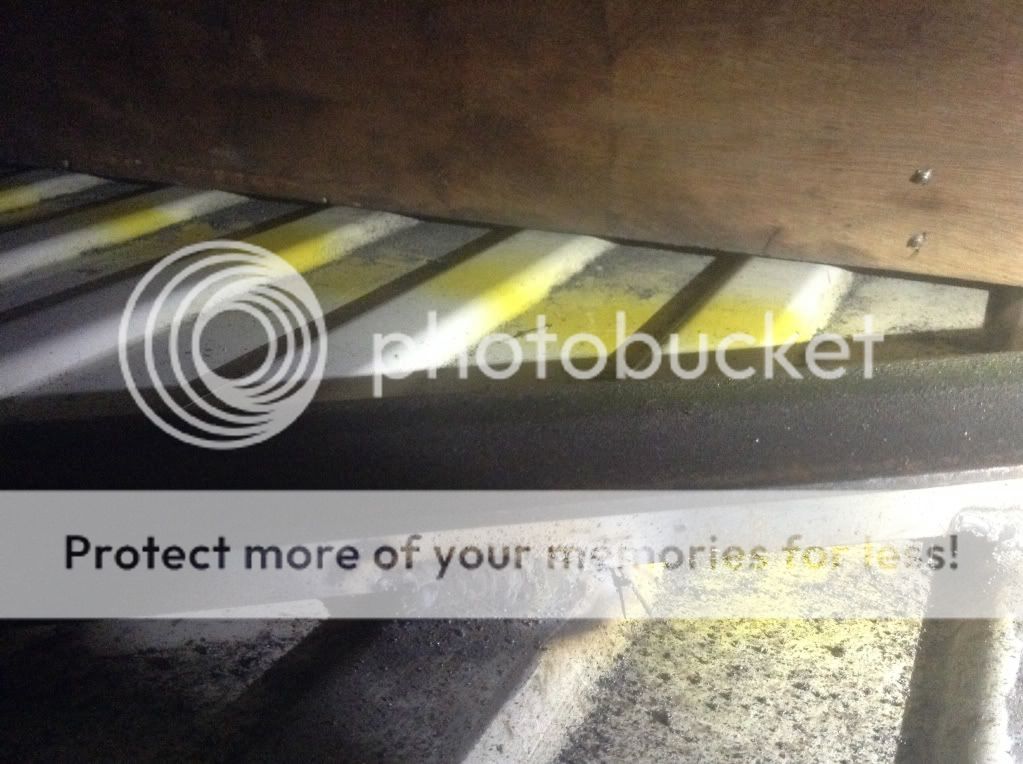

Anyway, I was quite impressed with my self when I welded some 40mm box section and 40mm angle together to make a bracket to hold a tyre machine down in my van. Found it quite easy to make a decent looking weld.

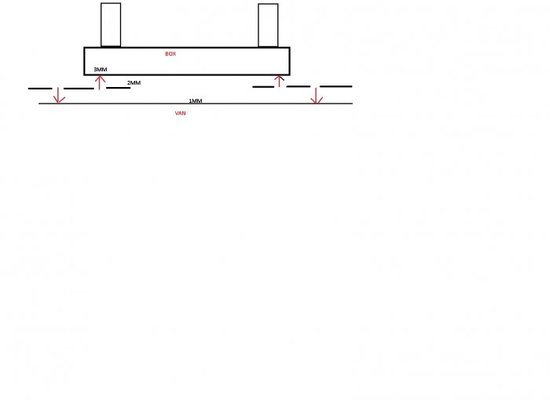

Now the problem arises when I try and weld said bracket to the floor of my van. The box section is 3mm thick, and the floor of my van I guess 1mm. The box section is rounded so there is a small gap between surfaces.

What happens is, when doing a uuuuuuuu pattern, the weld sticks to the box section, and sticks to the floor of the van, but not in between (until I go over it again)

Sometimes the wire will extend into the gap and stop the molten flow

The area is prepped, I am earthing the box section. The welder is on heat setting 4 (out of 6) and the speed is just past 12 o clock.

If I try and go slower I just burn through the floor, tried all different settings and all to no avail.

Sorry for the essay! I'm pretty sure the answer is to give up and pay somebody to do it, but I love trying things myself and it would be a valuable skill to hold.

Anyway, I have only been welding a week, I watched a few videos on YouTube then dived straight in. I have a wolf weld 135 MIG. I run it on 'no gas' with the flux cored wire. It is also positive ground.

Anyway, I was quite impressed with my self when I welded some 40mm box section and 40mm angle together to make a bracket to hold a tyre machine down in my van. Found it quite easy to make a decent looking weld.

Now the problem arises when I try and weld said bracket to the floor of my van. The box section is 3mm thick, and the floor of my van I guess 1mm. The box section is rounded so there is a small gap between surfaces.

What happens is, when doing a uuuuuuuu pattern, the weld sticks to the box section, and sticks to the floor of the van, but not in between (until I go over it again)

Sometimes the wire will extend into the gap and stop the molten flow

The area is prepped, I am earthing the box section. The welder is on heat setting 4 (out of 6) and the speed is just past 12 o clock.

If I try and go slower I just burn through the floor, tried all different settings and all to no avail.

Sorry for the essay! I'm pretty sure the answer is to give up and pay somebody to do it, but I love trying things myself and it would be a valuable skill to hold.