Wallace

Member

- Messages

- 7,791

- Location

- Staines, Middlesex, England.

I bought a TecArc 206i Tig and 46i Plasma cutter from Weldequip over 3 years ago and have been mulling over a Portamig ever since as I have been very impressed with both machines but unable to justify the outlay replacing my old Mig that still works well. A couple of jobs this year had left me feeling that the wirefeed was in need of repair or replacement so I looked into fitting the same wirefeed unit and Euro torch as fitted to the Portamig and a longer earth lead with a Dinze connector. Then came the dilema, do I invest nigh on £200 into my trusty 23 year old machine or pass it on and buy a Portamig? I found a buyer and ordered a Portamig 215!

In the meantime whilst the order was going through I stripped and serviced the wirefeed unit finding the grease had turned to glue and the machine was back to it's old consistent self so had I wasted my money? Only time can tell but at least I'm not passing on a faulty machine to a mate.

Only time can tell but at least I'm not passing on a faulty machine to a mate.

After a 3 week wait from ordering, the machine and accessories arrived within an hour or so of each other from two different couriers last Friday. I took my time (90 mins) assembling everything and laid a few welds on some scrap 3mm plate using Argoshield light and 0.8mm steel wire, everything worked as it should without any fuss feeling very smooth and consistent. Upping the voltage to No12 soon had the 3mm plate glowing and molten, it's quite fierce!

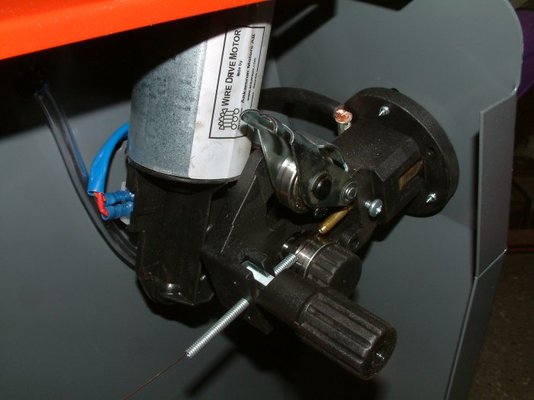

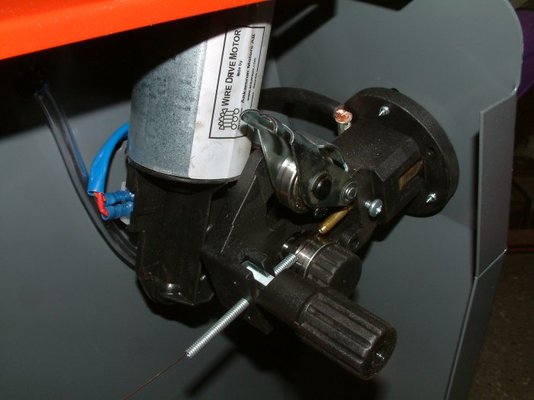

Swaping the wire to 0.6mm was a doddle as the wire feed unit has a quick release roller tensioner that stays set and the sprung loaded top roller arm flips neatly out of the way for access. The feed roller is held on with a thumb screw too so no tools are needed to change the wire size. These are two really nice features as my old Einhell SGA 175 Turbo has a wirefeed unit like the Sealey/Telwin machines that needs a thumbscrew removing to release the top roller and a screwdriver to change the wire size. Once changed you then have to reset the roller tension.

With 0.8mm sheet and the voltage setting down to No1 the beads were again nice and consistent and dropping the wire feed down gave the daintiest little bead you can do a signature on your work with! I decided a direct comparison would be in order with my old machine on the lowest setting laying a few beads next to eachother so with a Y piece on the bottle I set the machines up side by side and ran some beads on 0.8mm sheet.

I decided a direct comparison would be in order with my old machine on the lowest setting laying a few beads next to eachother so with a Y piece on the bottle I set the machines up side by side and ran some beads on 0.8mm sheet.

The Einhell works well and always has from day one, it's like a comfy old pair of shoes, I just pick the torch up and go hence I got a bit carried away playing with it before letting it go. In comparison to the Portamig on 0.8mm sheet you need to work faster with the Einhell, no two ways about it, hang around you blow through the sheet. The Portamig is definitely more controllable on 0.8mm sheet due to the lower voltage and gave me confidence in the machine straight away so it looks like I made the right decision to trade up.

In comparison to the Portamig on 0.8mm sheet you need to work faster with the Einhell, no two ways about it, hang around you blow through the sheet. The Portamig is definitely more controllable on 0.8mm sheet due to the lower voltage and gave me confidence in the machine straight away so it looks like I made the right decision to trade up.

Nice quick release, quick change features on the wirefeed

Added PVC edge trim to protect the paint from the gas bottle and temporary carpet until I can get rubber sheet!

2mm sheet with a mix of beads from both machines

0.8mm sheet with beads mainly from the old Einhell

0.8mm sheet, straight beads on the left from the Portamig and messing about with the spotweld timer on the Einhell.

In the meantime whilst the order was going through I stripped and serviced the wirefeed unit finding the grease had turned to glue and the machine was back to it's old consistent self so had I wasted my money?

Only time can tell but at least I'm not passing on a faulty machine to a mate.

Only time can tell but at least I'm not passing on a faulty machine to a mate.

After a 3 week wait from ordering, the machine and accessories arrived within an hour or so of each other from two different couriers last Friday. I took my time (90 mins) assembling everything and laid a few welds on some scrap 3mm plate using Argoshield light and 0.8mm steel wire, everything worked as it should without any fuss feeling very smooth and consistent. Upping the voltage to No12 soon had the 3mm plate glowing and molten, it's quite fierce!

Swaping the wire to 0.6mm was a doddle as the wire feed unit has a quick release roller tensioner that stays set and the sprung loaded top roller arm flips neatly out of the way for access. The feed roller is held on with a thumb screw too so no tools are needed to change the wire size. These are two really nice features as my old Einhell SGA 175 Turbo has a wirefeed unit like the Sealey/Telwin machines that needs a thumbscrew removing to release the top roller and a screwdriver to change the wire size. Once changed you then have to reset the roller tension.

With 0.8mm sheet and the voltage setting down to No1 the beads were again nice and consistent and dropping the wire feed down gave the daintiest little bead you can do a signature on your work with!

I decided a direct comparison would be in order with my old machine on the lowest setting laying a few beads next to eachother so with a Y piece on the bottle I set the machines up side by side and ran some beads on 0.8mm sheet.

I decided a direct comparison would be in order with my old machine on the lowest setting laying a few beads next to eachother so with a Y piece on the bottle I set the machines up side by side and ran some beads on 0.8mm sheet.The Einhell works well and always has from day one, it's like a comfy old pair of shoes, I just pick the torch up and go hence I got a bit carried away playing with it before letting it go.

In comparison to the Portamig on 0.8mm sheet you need to work faster with the Einhell, no two ways about it, hang around you blow through the sheet. The Portamig is definitely more controllable on 0.8mm sheet due to the lower voltage and gave me confidence in the machine straight away so it looks like I made the right decision to trade up.

In comparison to the Portamig on 0.8mm sheet you need to work faster with the Einhell, no two ways about it, hang around you blow through the sheet. The Portamig is definitely more controllable on 0.8mm sheet due to the lower voltage and gave me confidence in the machine straight away so it looks like I made the right decision to trade up.

Nice quick release, quick change features on the wirefeed

Added PVC edge trim to protect the paint from the gas bottle and temporary carpet until I can get rubber sheet!

2mm sheet with a mix of beads from both machines

0.8mm sheet with beads mainly from the old Einhell

0.8mm sheet, straight beads on the left from the Portamig and messing about with the spotweld timer on the Einhell.

Last edited:

Here are a couple of slightly out of focus photos showing the flow readings in comparison to the pressure gauge, all readings are done with the flowmeter resrictor open and the flow set by the regulator:

Here are a couple of slightly out of focus photos showing the flow readings in comparison to the pressure gauge, all readings are done with the flowmeter resrictor open and the flow set by the regulator:

The lower settings made the job a lot easier than using my old machine and I deliberately tried to make it look better than the patch at the other end of the sill from the previous year, it wasn't difficult to make it neat with the Portamig! His comment when he collected the car was that he had never seen such neat repair welding and would I be able to do more?

The lower settings made the job a lot easier than using my old machine and I deliberately tried to make it look better than the patch at the other end of the sill from the previous year, it wasn't difficult to make it neat with the Portamig! His comment when he collected the car was that he had never seen such neat repair welding and would I be able to do more?