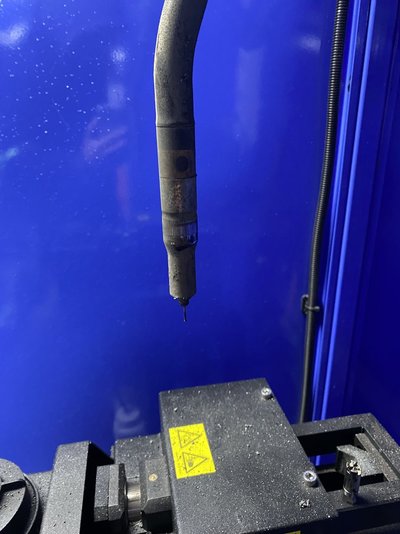

Hey guys, i know its now quite the place for robot welders? But I rate the question pertains to welding more than the welder.

Ok so we running production on 2 galvanized work pieces welded in 3 places

The issue I keep getting is a pin hole that shows up randomly. But when it does its in the same place of the weld (more or less center)

2 days ago showed up 20 parts out of 800 but yesterday it showed up way more with no setting changes and same batch of parts, weld pen on first off looked good too

We shielding with CO2

1.2mm wire

Panasonic robot welder

Any advice would be greatly appreciated.

Ok so we running production on 2 galvanized work pieces welded in 3 places

The issue I keep getting is a pin hole that shows up randomly. But when it does its in the same place of the weld (more or less center)

2 days ago showed up 20 parts out of 800 but yesterday it showed up way more with no setting changes and same batch of parts, weld pen on first off looked good too

We shielding with CO2

1.2mm wire

Panasonic robot welder

Any advice would be greatly appreciated.