Brad93

Member

- Messages

- 19,286

- Location

- Essex, United Kingdom

Looking for opinions on best way to proceed.

Quite often we have to remachine Cast Iron parts that are disc shaped, and quite easily distorted by both four and three jaw chuck with soft jaws turned to size.

We use these 315mm super precision chucks.

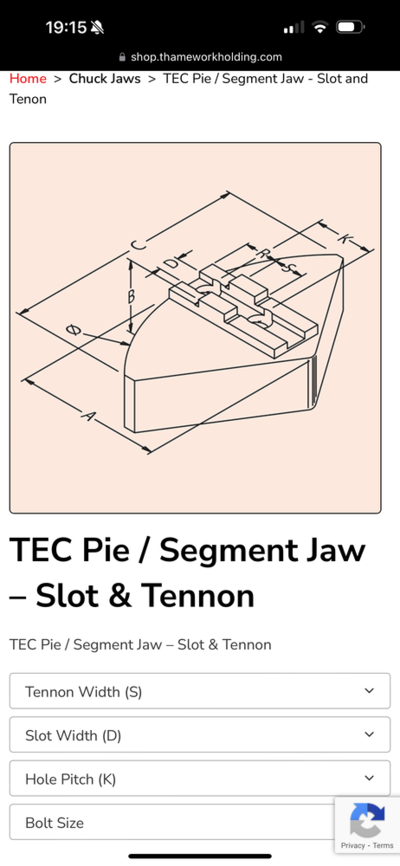

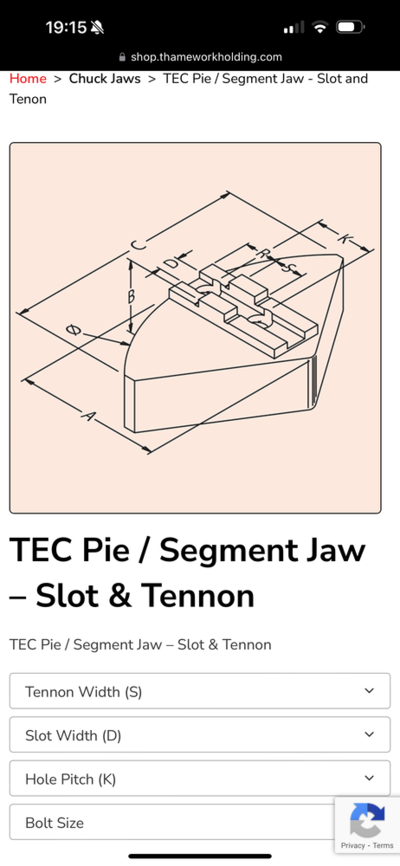

Unfortunately we don't have the two part jaws just solid jaws. which would enable use to use something like this:

We use the standard Thame Workholding soft jaws already.

I can see only two options -

Machine a set of soft jaws into some sort of two part jaw to accept the pie shaped segments which could be waterjet cut.

or buy a two part jaw chuck and buy in the ready made jaws.

Of course the company would rather do the first one, i'd prefer not to get behind on any work making something and just buy in what is needed, especially since the chucks haven't been well looked after anyway, a new one would be a good investment.

What's your opinions?

Quite often we have to remachine Cast Iron parts that are disc shaped, and quite easily distorted by both four and three jaw chuck with soft jaws turned to size.

We use these 315mm super precision chucks.

Unfortunately we don't have the two part jaws just solid jaws. which would enable use to use something like this:

We use the standard Thame Workholding soft jaws already.

I can see only two options -

Machine a set of soft jaws into some sort of two part jaw to accept the pie shaped segments which could be waterjet cut.

or buy a two part jaw chuck and buy in the ready made jaws.

Of course the company would rather do the first one, i'd prefer not to get behind on any work making something and just buy in what is needed, especially since the chucks haven't been well looked after anyway, a new one would be a good investment.

What's your opinions?