Hood

I am obsessed.

- Messages

- 17,603

- Location

- Carnoustie, Scotland

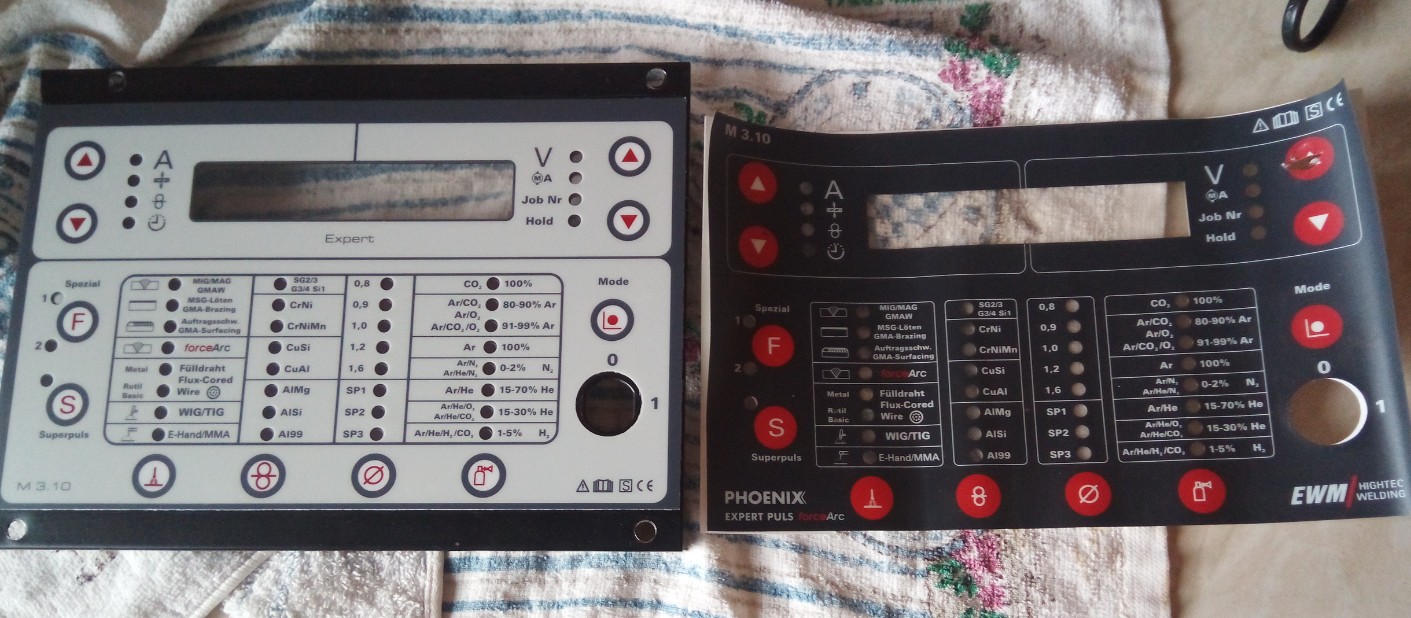

A month or so ago the overlay on the EWM took a knock and it burst through.

The button underneath seemed fine so as a temporary repair I just shoved some tape over it to keep the muck out but it was a shame as the welder was like new when I got it so decided to see if a new overlay could be purchased.

It could and I had prepared myself before opening the email from @Jim Davey , I was comfortably seated with oxygen and defibrillator on hand After I regained my composure I had to ponder about whether to get it or not because although it was available it was in the newer EWM colours rather than the older colours of my machine. Decided in the end that it was better than just having a bit of tape over the damage.

After I regained my composure I had to ponder about whether to get it or not because although it was available it was in the newer EWM colours rather than the older colours of my machine. Decided in the end that it was better than just having a bit of tape over the damage.

So today was the day for replacement. I decided my workshop was not the best place for this so elected to remove the panel. It was held on by 4 Torx screws and when eased out it was just the simple case of removing an earth wire and a D-Sub plug.

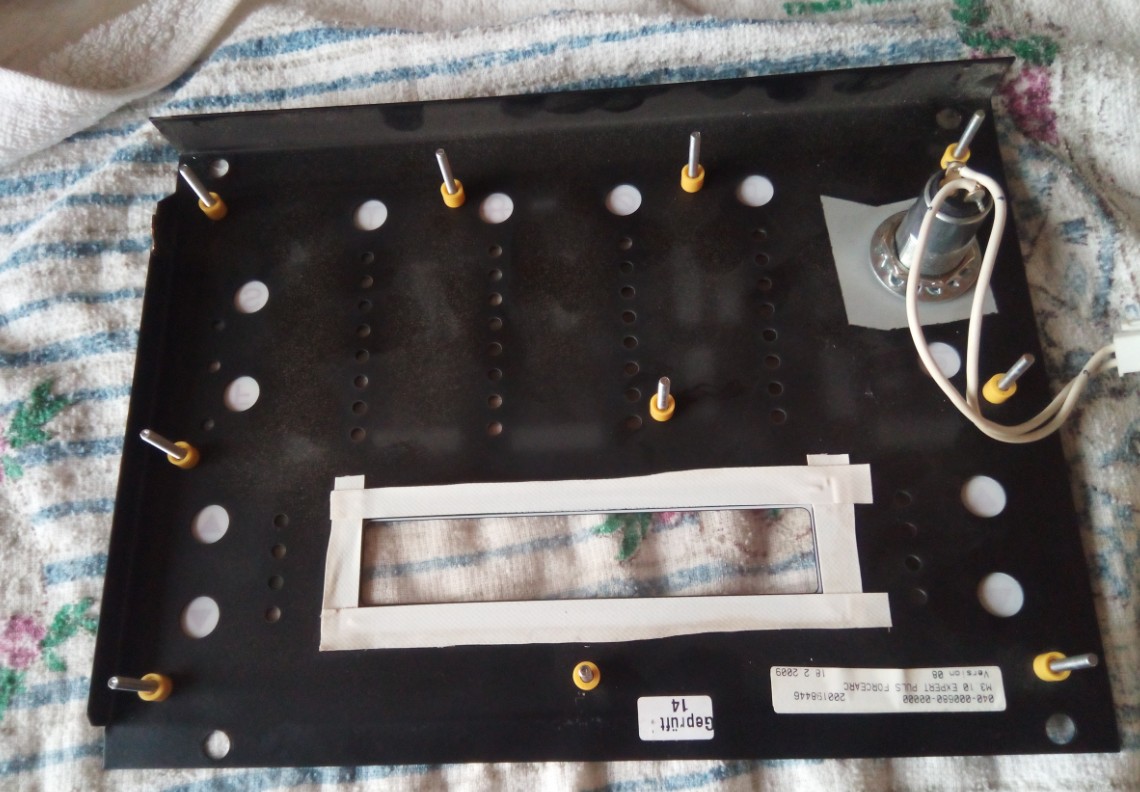

First step was to remove the circuit boards, easy enough as they were just held on with plastic tube nuts.

Top board removed.

Then the lower board.

Had to remove the key switch and then was able to start removing the overlay.

Used a hair dryer to heat it up and it came of surprisingly easily and didn't even leave any glue residue on the metal. Positioned the overlay and then proceeded to stick it in place. It was quite easy to do as the protective peel off covering on the back was in two parts so I was able to hold the overlay in place, lift up the left side and remove the smaller portion of covering and then smooth that down onto the metal. The rest was just as easy because now the first portion was holding it in place so I could just peel and press as I went.

All done and looking strange.

I then rebuilt the panel and only then did I discover that the tactile button on the PCB did not feel right Had to remove the PCB's again and discovered that the actuator had been pulled sideways. I managed to place it back into position and melt the remnants of the stubs, that hold the metal cover in place, with a hot knife. Job done and it seems to be working as it clicks like it should but tomorrow will be when I know for sure, if not it should be easy enough to get a new switch from RS or the likes.

Had to remove the PCB's again and discovered that the actuator had been pulled sideways. I managed to place it back into position and melt the remnants of the stubs, that hold the metal cover in place, with a hot knife. Job done and it seems to be working as it clicks like it should but tomorrow will be when I know for sure, if not it should be easy enough to get a new switch from RS or the likes.

The button underneath seemed fine so as a temporary repair I just shoved some tape over it to keep the muck out but it was a shame as the welder was like new when I got it so decided to see if a new overlay could be purchased.

It could and I had prepared myself before opening the email from @Jim Davey , I was comfortably seated with oxygen and defibrillator on hand

After I regained my composure I had to ponder about whether to get it or not because although it was available it was in the newer EWM colours rather than the older colours of my machine. Decided in the end that it was better than just having a bit of tape over the damage.

After I regained my composure I had to ponder about whether to get it or not because although it was available it was in the newer EWM colours rather than the older colours of my machine. Decided in the end that it was better than just having a bit of tape over the damage.So today was the day for replacement. I decided my workshop was not the best place for this so elected to remove the panel. It was held on by 4 Torx screws and when eased out it was just the simple case of removing an earth wire and a D-Sub plug.

First step was to remove the circuit boards, easy enough as they were just held on with plastic tube nuts.

Top board removed.

Then the lower board.

Had to remove the key switch and then was able to start removing the overlay.

Used a hair dryer to heat it up and it came of surprisingly easily and didn't even leave any glue residue on the metal. Positioned the overlay and then proceeded to stick it in place. It was quite easy to do as the protective peel off covering on the back was in two parts so I was able to hold the overlay in place, lift up the left side and remove the smaller portion of covering and then smooth that down onto the metal. The rest was just as easy because now the first portion was holding it in place so I could just peel and press as I went.

All done and looking strange.

I then rebuilt the panel and only then did I discover that the tactile button on the PCB did not feel right

Had to remove the PCB's again and discovered that the actuator had been pulled sideways. I managed to place it back into position and melt the remnants of the stubs, that hold the metal cover in place, with a hot knife. Job done and it seems to be working as it clicks like it should but tomorrow will be when I know for sure, if not it should be easy enough to get a new switch from RS or the likes.

Had to remove the PCB's again and discovered that the actuator had been pulled sideways. I managed to place it back into position and melt the remnants of the stubs, that hold the metal cover in place, with a hot knife. Job done and it seems to be working as it clicks like it should but tomorrow will be when I know for sure, if not it should be easy enough to get a new switch from RS or the likes.