lobsterissmus

New Member

- Messages

- 4

Hi all,

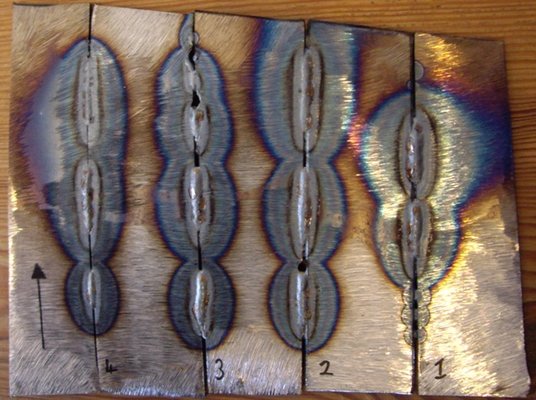

Today I have mostly been practicing my welding on some 1.6mm sheet strips - any comments appreciated ! It's been three years since I did my basic C&G Mig course, on 6mm plate, so welding thin stuff is new to me!

! It's been three years since I did my basic C&G Mig course, on 6mm plate, so welding thin stuff is new to me!

I'm using an old Murex Trademig 160 at its lowest voltage setting.

1st pic shows vertical welds, basically playing with speed setting and gap between plates. 2nd pic shows penetration. I think run (4) shows the best results.

3rd & 4th pics show horizontal welding on vertical plates, adjusting gap only. Run (2) seems okay but I need to work on better penetration where I've tacked the plates together.

Anyway assuming I can learn to get better penetration of the tack welds, does my welding look up to the job? Anything I can improve on?

Today I have mostly been practicing my welding on some 1.6mm sheet strips - any comments appreciated

! It's been three years since I did my basic C&G Mig course, on 6mm plate, so welding thin stuff is new to me!

! It's been three years since I did my basic C&G Mig course, on 6mm plate, so welding thin stuff is new to me!I'm using an old Murex Trademig 160 at its lowest voltage setting.

1st pic shows vertical welds, basically playing with speed setting and gap between plates. 2nd pic shows penetration. I think run (4) shows the best results.

3rd & 4th pics show horizontal welding on vertical plates, adjusting gap only. Run (2) seems okay but I need to work on better penetration where I've tacked the plates together.

Anyway assuming I can learn to get better penetration of the tack welds, does my welding look up to the job? Anything I can improve on?

.

.