Sorry for long post, trying to understand how it works.

This is about CEA "Digistar 250 dual-pulsed" welder which welds correctly with 0.8 mm wire in either synergic (program 001) or "MIG-MAG MANual" (based on syn 001) mode.

There are no synergic programs for 0.6 mm wire, programs 000 (0.6 with CO2) and 010 (0.6 with Ar/CO2 80/20%) not installed by factory.

Feeding of 0.6 mm wire has been sorted out, described in another thread, but welding with that wire is another matter. I have doubts that real manual mode is accessible at all.

One can select "MIG-MAG MAN" procedure but the manual mentions that the basis for that is a selected synergic program. It talks about adjustments to wire speed and voltage as preset by the synergic program and it seems to be true. Different syn-programs have for example different lowest wire speeds and one simply cannot set wire speed parameters outside of chosen syn-program. Which for me means that there is no escape from synergic programs so no real manual mode. What do you think?

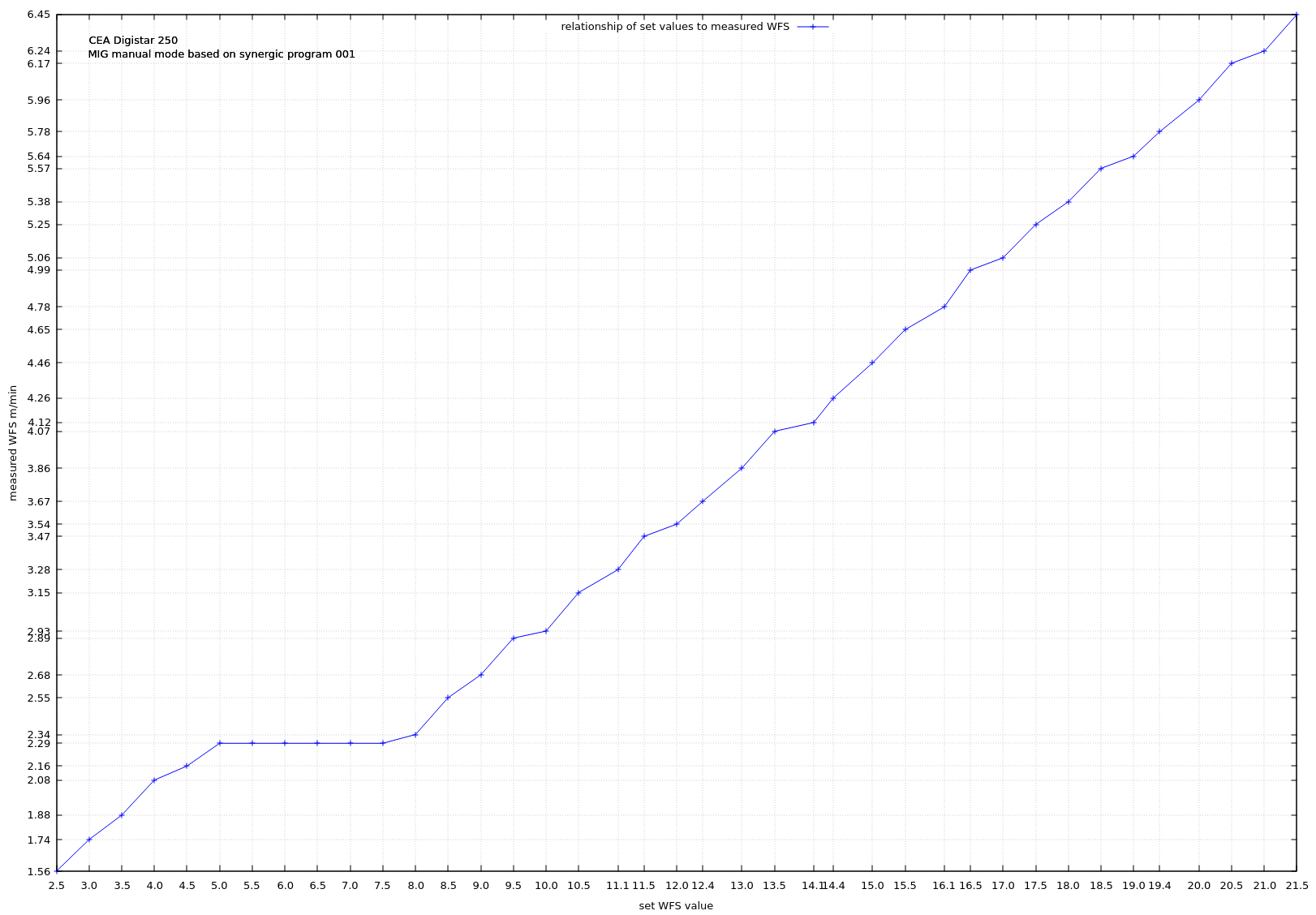

I discovered that the wire speed numbers on display do not correspond to meters/minute. For synergic program 001 the lowest speed is 2.5 and highest 21.5, in reality 2.5 on display is ~1.6 m/min, 5.0 on display ~2.3 m/min and 10 ~2.9 m/min. Checked with straight torch cable, no tip and no reel brake. Also averaged over four 4 second runs, because the wire feed stops automatically after 4 secs when no arcing.

I also discovered that the displayed number 2.5 is not absolute, meaning the number has different meaning in different synergic programs, for example:

PROGRAM 001 ~1.6 m/min (Fe 0.8 CO2)

PROGRAM 002 ~1.3 m/min (Fe 1.0 CO2)

PROGRAM 011 ~1.35 m/min (Fe 0.8 Ar/CO2 80/20%)

PROGRAM 012 ~1.5 m/min (Fe 1.0 Ar/CO2 80/20%)

PROGRAM 202 ~1.95 m/min (CrNi 316 1.0 Ar/CO2 98/2%)

PROGRAM 522 ~1.1 m/min (Brazing, S Cu Al8 1.0 Ar 100%)

Once I discovered the nonlinear discrepancy between displayed numbers and real WFS I had some success. With WFS ~2.8 m/min it welds, but blows through 0.8 mm sheet in no time. Arc is fierce as if voltage is high and fiddling with voltage does not help. I will talk with local reseller but they are clueless. When asked how to set wire speed below 2.5 m/min, because 1 m/min is written in tech specs they mumbled something about submenus and getting soon back to me. When they got back they did not have any answers, only more mumbling.

BTW, several years back I had no problem dialing in Kemppi FU20, with two knobs and one tumbler. Got this used CEA because price was right and features good, with 4R feed. Tried both aluminium and steel on demonstration, but did not have 0.6 wire with me and didn't give much attention because per the specs it seemed fully capable.

This is about CEA "Digistar 250 dual-pulsed" welder which welds correctly with 0.8 mm wire in either synergic (program 001) or "MIG-MAG MANual" (based on syn 001) mode.

There are no synergic programs for 0.6 mm wire, programs 000 (0.6 with CO2) and 010 (0.6 with Ar/CO2 80/20%) not installed by factory.

Feeding of 0.6 mm wire has been sorted out, described in another thread, but welding with that wire is another matter. I have doubts that real manual mode is accessible at all.

One can select "MIG-MAG MAN" procedure but the manual mentions that the basis for that is a selected synergic program. It talks about adjustments to wire speed and voltage as preset by the synergic program and it seems to be true. Different syn-programs have for example different lowest wire speeds and one simply cannot set wire speed parameters outside of chosen syn-program. Which for me means that there is no escape from synergic programs so no real manual mode. What do you think?

I discovered that the wire speed numbers on display do not correspond to meters/minute. For synergic program 001 the lowest speed is 2.5 and highest 21.5, in reality 2.5 on display is ~1.6 m/min, 5.0 on display ~2.3 m/min and 10 ~2.9 m/min. Checked with straight torch cable, no tip and no reel brake. Also averaged over four 4 second runs, because the wire feed stops automatically after 4 secs when no arcing.

I also discovered that the displayed number 2.5 is not absolute, meaning the number has different meaning in different synergic programs, for example:

PROGRAM 001 ~1.6 m/min (Fe 0.8 CO2)

PROGRAM 002 ~1.3 m/min (Fe 1.0 CO2)

PROGRAM 011 ~1.35 m/min (Fe 0.8 Ar/CO2 80/20%)

PROGRAM 012 ~1.5 m/min (Fe 1.0 Ar/CO2 80/20%)

PROGRAM 202 ~1.95 m/min (CrNi 316 1.0 Ar/CO2 98/2%)

PROGRAM 522 ~1.1 m/min (Brazing, S Cu Al8 1.0 Ar 100%)

Once I discovered the nonlinear discrepancy between displayed numbers and real WFS I had some success. With WFS ~2.8 m/min it welds, but blows through 0.8 mm sheet in no time. Arc is fierce as if voltage is high and fiddling with voltage does not help. I will talk with local reseller but they are clueless. When asked how to set wire speed below 2.5 m/min, because 1 m/min is written in tech specs they mumbled something about submenus and getting soon back to me. When they got back they did not have any answers, only more mumbling.

BTW, several years back I had no problem dialing in Kemppi FU20, with two knobs and one tumbler. Got this used CEA because price was right and features good, with 4R feed. Tried both aluminium and steel on demonstration, but did not have 0.6 wire with me and didn't give much attention because per the specs it seemed fully capable.