rosinante

Member

- Messages

- 1,346

- Location

- Cornwall England

Hi All,

we use nitrogen at work for motive gas at 9bar and for furnace quench at 15bar,the gas is produced by vaporisers from a large LN2 cryo vessel outside the factory, it is piped into the building in 2" copper pipes,the motive gas consumption is very small and poses no problem,the quench gas is fed to large [50cubic M] buffer tanks to provide a large reservoir for quenching the Vac furnaces, when filling the buffer tanks the noise from the pipework is horrendous vibrating/resonating throughout the building

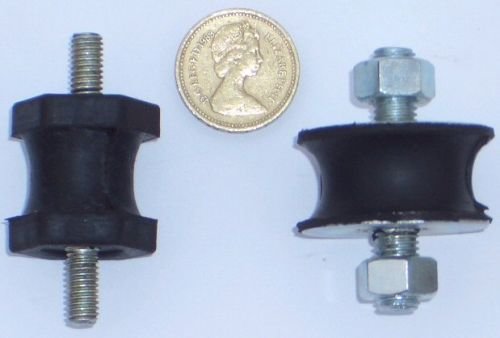

,there are numerous 90 bends and the inaccessible overhead pipe work is about 35M long with no flexible connections in it,as the pressures in the buffer tanks near max the noise increases,the level is such that ear defenders are a must although there are no site req or signs for them,all pipe supports are metal clamps with no rubber in,are there any quick /cheap solutions?? any ideas welcome,I am not a mechanical engineer just a simple spark whos goin deaf!!!

,there are numerous 90 bends and the inaccessible overhead pipe work is about 35M long with no flexible connections in it,as the pressures in the buffer tanks near max the noise increases,the level is such that ear defenders are a must although there are no site req or signs for them,all pipe supports are metal clamps with no rubber in,are there any quick /cheap solutions?? any ideas welcome,I am not a mechanical engineer just a simple spark whos goin deaf!!!

Thanks

Chris

we use nitrogen at work for motive gas at 9bar and for furnace quench at 15bar,the gas is produced by vaporisers from a large LN2 cryo vessel outside the factory, it is piped into the building in 2" copper pipes,the motive gas consumption is very small and poses no problem,the quench gas is fed to large [50cubic M] buffer tanks to provide a large reservoir for quenching the Vac furnaces, when filling the buffer tanks the noise from the pipework is horrendous vibrating/resonating throughout the building

,there are numerous 90 bends and the inaccessible overhead pipe work is about 35M long with no flexible connections in it,as the pressures in the buffer tanks near max the noise increases,the level is such that ear defenders are a must although there are no site req or signs for them,all pipe supports are metal clamps with no rubber in,are there any quick /cheap solutions?? any ideas welcome,I am not a mechanical engineer just a simple spark whos goin deaf!!!

,there are numerous 90 bends and the inaccessible overhead pipe work is about 35M long with no flexible connections in it,as the pressures in the buffer tanks near max the noise increases,the level is such that ear defenders are a must although there are no site req or signs for them,all pipe supports are metal clamps with no rubber in,are there any quick /cheap solutions?? any ideas welcome,I am not a mechanical engineer just a simple spark whos goin deaf!!!Thanks

Chris