SUZUKI ROCKS

Member

- Messages

- 55

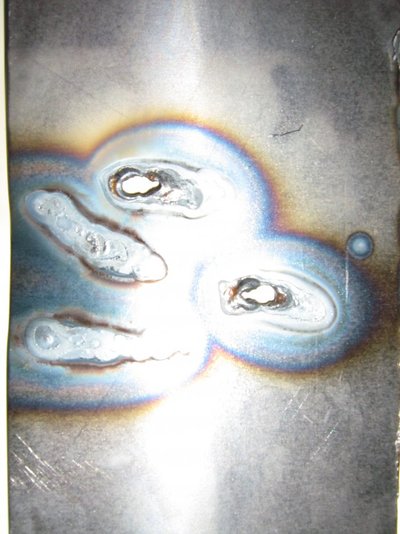

Did my first practice welds today and think i must be doing somthing wrong becouse i cant seem to get ant penitration through the steel! The steel is 1mm thick and im using a clarke 130en machine set up for gas welding with 0.6 mm wire.

First i tryed the settings sugested in the manual for 0.8-1.0mm steel (switch A = 2, switch B = MIN) but with a slower wire speed, 4, manual sugests 5-6. Gas set to 4.

As you can see(if i figure out how to put photos on ) With this setting the welder made a regular poping sound, not a crackling and the welds seem to be like seperate dots, not a continuous bead. Then i increased the wire speed and the sound and feel improved but still no penitation!

) With this setting the welder made a regular poping sound, not a crackling and the welds seem to be like seperate dots, not a continuous bead. Then i increased the wire speed and the sound and feel improved but still no penitation!

I played around with power settings and wire/gas speed and although i got diffrend weld/sounds/feel still no proper penitration. Then set the macine up for 1.0 - 2.0 mm (A=1 b=max, Wire speed = 6). This setting felt good but burnt holes in the steel but without proper/desired weld penitration!

So guys, what am i doing wrong? There is suposed to be weld penitration right? Or is the top weld enough to join 2 bits of metal together?

This is soooo much harder then i thoght and i take my hat(helmet) of to you guys

Please help.

Thank you

First i tryed the settings sugested in the manual for 0.8-1.0mm steel (switch A = 2, switch B = MIN) but with a slower wire speed, 4, manual sugests 5-6. Gas set to 4.

As you can see(if i figure out how to put photos on

) With this setting the welder made a regular poping sound, not a crackling and the welds seem to be like seperate dots, not a continuous bead. Then i increased the wire speed and the sound and feel improved but still no penitation!

) With this setting the welder made a regular poping sound, not a crackling and the welds seem to be like seperate dots, not a continuous bead. Then i increased the wire speed and the sound and feel improved but still no penitation!I played around with power settings and wire/gas speed and although i got diffrend weld/sounds/feel still no proper penitration. Then set the macine up for 1.0 - 2.0 mm (A=1 b=max, Wire speed = 6). This setting felt good but burnt holes in the steel but without proper/desired weld penitration!

So guys, what am i doing wrong? There is suposed to be weld penitration right? Or is the top weld enough to join 2 bits of metal together?

This is soooo much harder then i thoght and i take my hat(helmet) of to you guys

Please help.

Thank you