Good afternoon everybody,

I've recently got myself a new to me ACDC parweld xtt202 with cooler.

This isn't so much of a question thread but as a way to ask for tips etc while keeping a note of my progress.

My main goal for my Tig unit is to fabricate parts for my project vehicles (another thread) and a bit of bodywork.

Although I have limited experience (a Tig night class several years ago) I have been using a mig for quite some time.

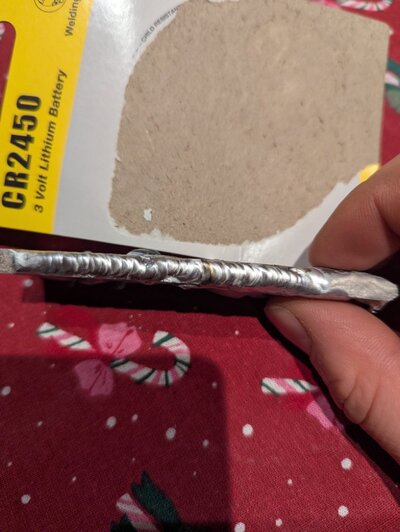

So here are my first couple of welds on thin material then moved to thicker plate (much easier) and my first little go on alloy.

I'll update as I progress but any advice is welcome and I'm sure I'll have some questions as I progress.

I've recently got myself a new to me ACDC parweld xtt202 with cooler.

This isn't so much of a question thread but as a way to ask for tips etc while keeping a note of my progress.

My main goal for my Tig unit is to fabricate parts for my project vehicles (another thread) and a bit of bodywork.

Although I have limited experience (a Tig night class several years ago) I have been using a mig for quite some time.

So here are my first couple of welds on thin material then moved to thicker plate (much easier) and my first little go on alloy.

I'll update as I progress but any advice is welcome and I'm sure I'll have some questions as I progress.