So my new tig welder /inverter arrived yesterday  ,courtesy of weldequip

,courtesy of weldequip

Many years ago at college i did a bit of gas and mig welding ,but all my tig is self tought , so its far from perfect

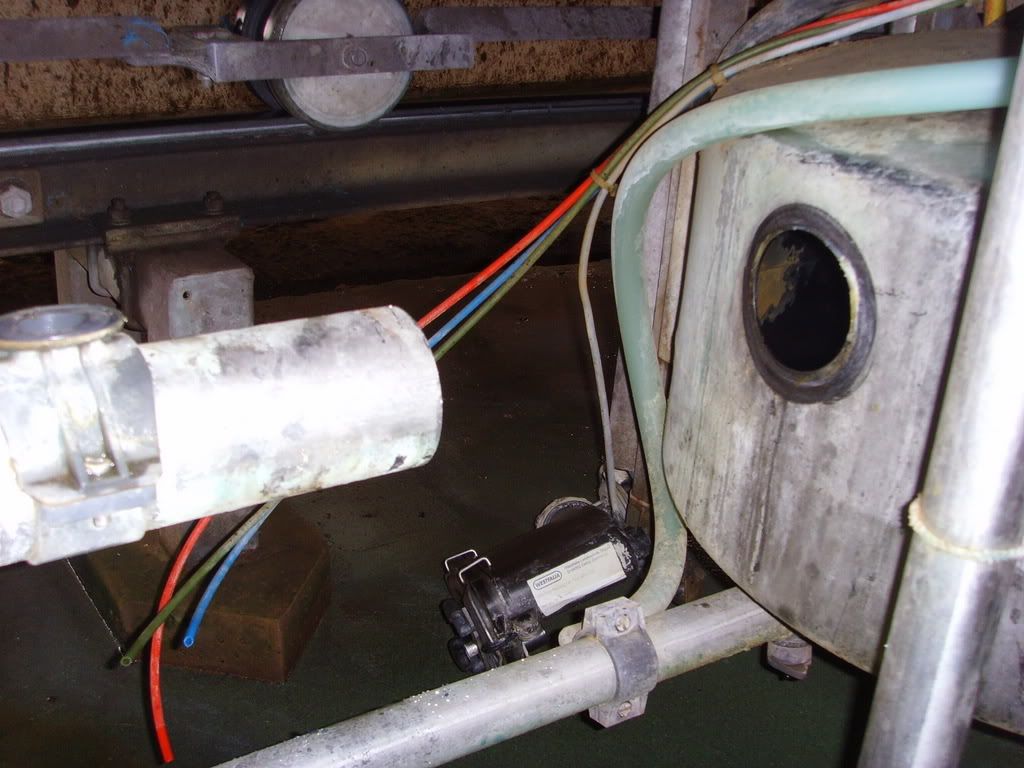

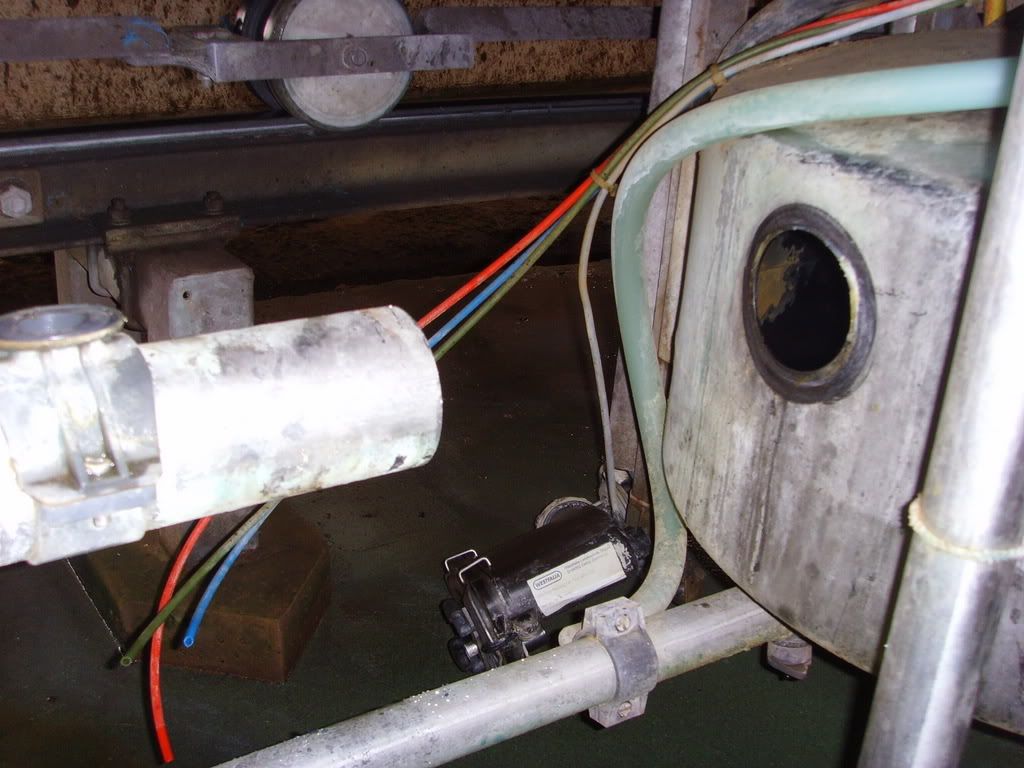

just thought id share with a few pictures the job i did today with the new machine . This is a milk reciever on a rotary milking parlour

The job was do away with the rubber fitting ,which has an elbow inside the vessel to wash the inside .when its on a wash cycle ,after milking .

Having cut out a short section of pipe, a new piece is cut using the excellent ( but chinese im afraid )evolution chop saw ,incidently fitted with a stainless cutting blade .

)evolution chop saw ,incidently fitted with a stainless cutting blade .

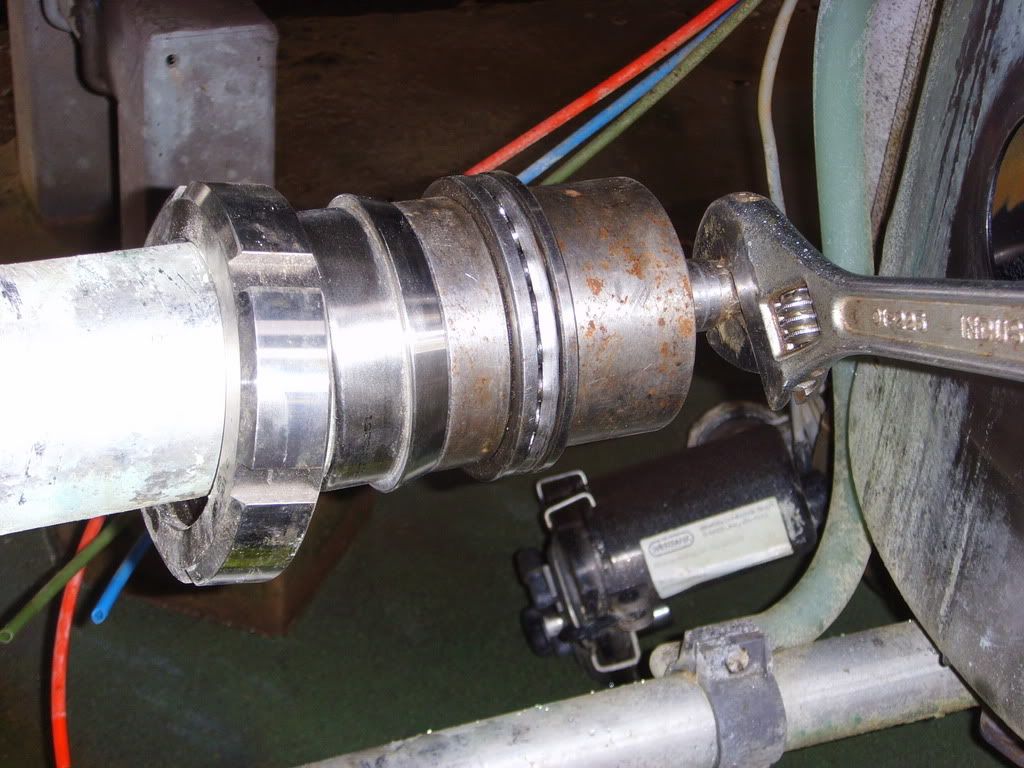

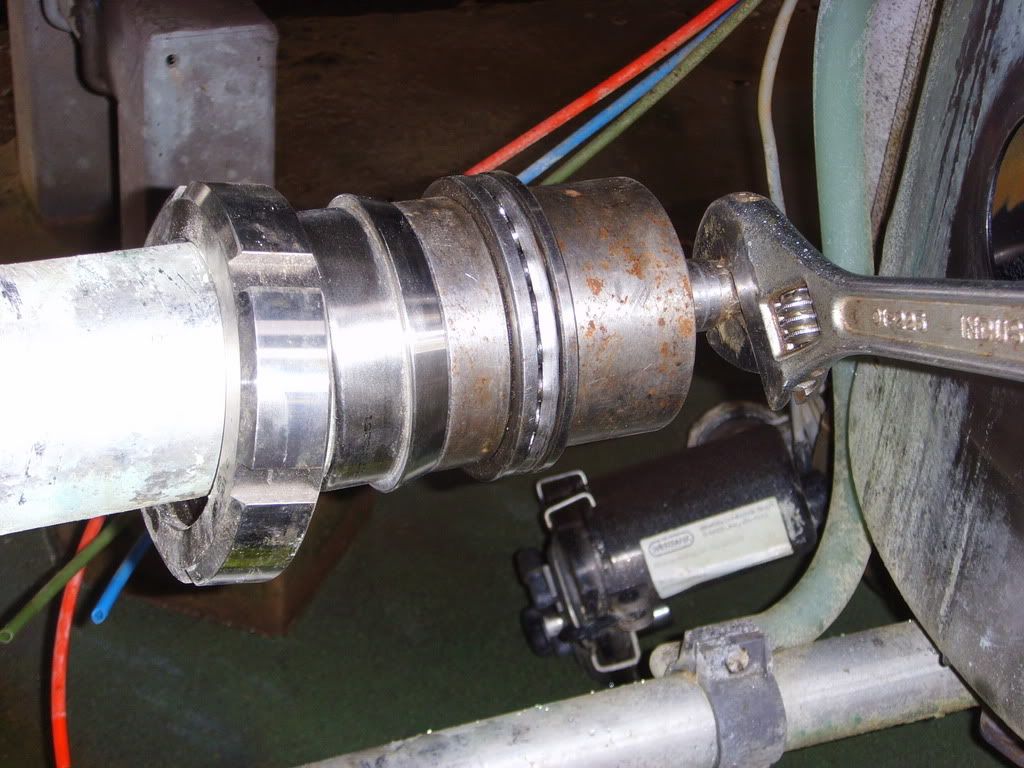

Then a new union is swaged on ....

Finally a large 'washer ' which i had to cut out using 2 hole saws was fitted up against the vessel (must get a plasma cutter when funds allow ) and welded round /cleaned up

close up please feel free to make any comments good or bad about the welding

Finally heres the kit i used .....

Cheers mike

,courtesy of weldequip

,courtesy of weldequip Many years ago at college i did a bit of gas and mig welding ,but all my tig is self tought , so its far from perfect

just thought id share with a few pictures the job i did today with the new machine . This is a milk reciever on a rotary milking parlour

The job was do away with the rubber fitting ,which has an elbow inside the vessel to wash the inside .when its on a wash cycle ,after milking .

Having cut out a short section of pipe, a new piece is cut using the excellent ( but chinese im afraid

)evolution chop saw ,incidently fitted with a stainless cutting blade .

)evolution chop saw ,incidently fitted with a stainless cutting blade .

Then a new union is swaged on ....

Finally a large 'washer ' which i had to cut out using 2 hole saws was fitted up against the vessel (must get a plasma cutter when funds allow ) and welded round /cleaned up

close up please feel free to make any comments good or bad about the welding

Finally heres the kit i used .....

Cheers mike