Good morning all, or at least it's morning here on the east coast in the states. Got a question for ya, but first, a bit of background.

I'm 60. I learned to weld years ago on a 220 AC/DC buzz box. A buddy of mine was retiring, and I bought out his shop maybe 15 years ago, and as part of the deal, got a top of the line Lincoln 120V MIG welder. Because I do mostly heavier stuff (not sheet metal), I switched it from .023 wire to .030 (I use Ar/CO2 gas for flux), and never looked back. I sold the buzz box.

Over the last few years, I have hardly used the MIG. Now I have a project, so took the MIG to my friendly local welding shop to be tuned up (it wasn't feeding well), and now I need some advice.

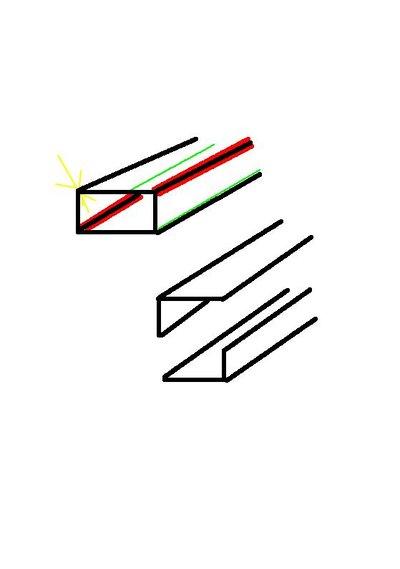

What I want to do is build some tubing to slide in 2X3 rectangular tubing with a 3/16 wall. The inside dimensions are 2-5/8 and 1-5/8. It seems to me that I want to cut my 3/16 sheet to 2-1/4 and 1-1/4, and the corner welds will essentially be the radius that fills the corners and fits into the 2X3 tubing.

Does that make sense? Certainly I will play around with this before making the final product, but I would very much appreciate any suggestions.

Thanks!

Frank

I'm 60. I learned to weld years ago on a 220 AC/DC buzz box. A buddy of mine was retiring, and I bought out his shop maybe 15 years ago, and as part of the deal, got a top of the line Lincoln 120V MIG welder. Because I do mostly heavier stuff (not sheet metal), I switched it from .023 wire to .030 (I use Ar/CO2 gas for flux), and never looked back. I sold the buzz box.

Over the last few years, I have hardly used the MIG. Now I have a project, so took the MIG to my friendly local welding shop to be tuned up (it wasn't feeding well), and now I need some advice.

What I want to do is build some tubing to slide in 2X3 rectangular tubing with a 3/16 wall. The inside dimensions are 2-5/8 and 1-5/8. It seems to me that I want to cut my 3/16 sheet to 2-1/4 and 1-1/4, and the corner welds will essentially be the radius that fills the corners and fits into the 2X3 tubing.

Does that make sense? Certainly I will play around with this before making the final product, but I would very much appreciate any suggestions.

Thanks!

Frank

.

.

Still don't come home smelling of coolant oil.

Still don't come home smelling of coolant oil.