gasket999

getting there...

- Messages

- 366

- Location

- Manchester, UK

Hi folks.

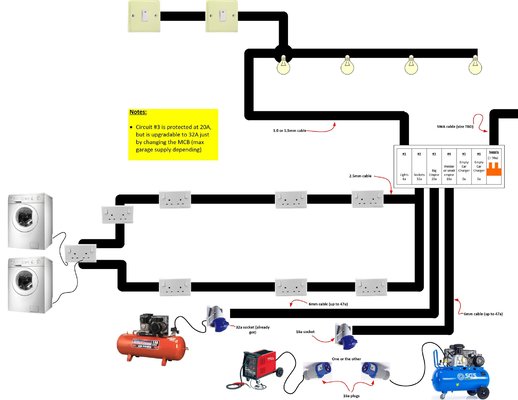

my garage consumer unit has a good 50a supply, from which I have a ring of sockets on a dedicated 16a MCB, two vacant MCB ports (future proof as when we get electric cars I’ll need to add chargers) and one that I’m looking to use for my larger amp needs (compressor and welding set).

I have a Clarke 160TM welder (says it needs a 16a supply) and a 3hp belt drive 150L compressor (advice is that it needs a 20A supply).

I’m about to tandem-in a second 3hp compressor - but the pressure switches will be set so they don’t start at the same time. I also won’t be running both a compressor and a welder at the same time.

So I’d like to have a single new ring - with three sockets to connect to the welder and the two compressors.

To that end this is my current thought:

1) fit a 20a MCB

2) from this run 10mm cable to the three 32A wall mounted commando sockets.

3) fit 32a commando sockets to the welder and two compressors.

nb the above would be a radial circuit, not a ring. Like the other socket ring in the garage, it will be surface mounted in round plastic MK conduit and matching joints/elbows/tees.

10mm is obviously bigger than needed for 32A, but means if I ever need 40a I don’t have to change the cable - I just have to swap the sockets for fused switches and change the MCB.

Assuming the above makes sense, could anyone help me with a few queries.

1) is it possible/advised to have both the welder (max 16a) and the compressor (max 20a) on the same circuit? I suppose the nightmare is that the welder goes wrong and it gets the full 20a before melting.

2)is it ok for the sockets to be over engineered for the need (32a socket, 20a requirement) and for the cable to be over engineered for the need (10mm2 on a 20a circuit) provided that the MCB is appropriate to the machines (20a)?

3) would it be advisable to fit a type c (or even d) breaker?

thank you very much. I should point out that, like my last workshop build, I do have a qualified electrician lined up to inspect the install, terminate the cables and test. All I do is buy the components, fit all the conduit and loosely run the cables ready for him.

keeps the cost down and also lets me faff around with positioning and making sure the runs are obsessively level!

thank you.

my garage consumer unit has a good 50a supply, from which I have a ring of sockets on a dedicated 16a MCB, two vacant MCB ports (future proof as when we get electric cars I’ll need to add chargers) and one that I’m looking to use for my larger amp needs (compressor and welding set).

I have a Clarke 160TM welder (says it needs a 16a supply) and a 3hp belt drive 150L compressor (advice is that it needs a 20A supply).

I’m about to tandem-in a second 3hp compressor - but the pressure switches will be set so they don’t start at the same time. I also won’t be running both a compressor and a welder at the same time.

So I’d like to have a single new ring - with three sockets to connect to the welder and the two compressors.

To that end this is my current thought:

1) fit a 20a MCB

2) from this run 10mm cable to the three 32A wall mounted commando sockets.

3) fit 32a commando sockets to the welder and two compressors.

nb the above would be a radial circuit, not a ring. Like the other socket ring in the garage, it will be surface mounted in round plastic MK conduit and matching joints/elbows/tees.

10mm is obviously bigger than needed for 32A, but means if I ever need 40a I don’t have to change the cable - I just have to swap the sockets for fused switches and change the MCB.

Assuming the above makes sense, could anyone help me with a few queries.

1) is it possible/advised to have both the welder (max 16a) and the compressor (max 20a) on the same circuit? I suppose the nightmare is that the welder goes wrong and it gets the full 20a before melting.

2)is it ok for the sockets to be over engineered for the need (32a socket, 20a requirement) and for the cable to be over engineered for the need (10mm2 on a 20a circuit) provided that the MCB is appropriate to the machines (20a)?

3) would it be advisable to fit a type c (or even d) breaker?

thank you very much. I should point out that, like my last workshop build, I do have a qualified electrician lined up to inspect the install, terminate the cables and test. All I do is buy the components, fit all the conduit and loosely run the cables ready for him.

keeps the cost down and also lets me faff around with positioning and making sure the runs are obsessively level!

thank you.