Roop

Crisis? What crisis?

- Messages

- 23

I just could not resist, I bought one of the many Plasmacutter clones. I bought it from Felzen GmbH in Germany and paid approx. €280. delivered to the Netherlands. Shipment and delivery were ok. After a quick check I connected the airsupply and started cutting some 5mm. angle iron. Like a hot knife through butter. At full power the 16A fuse in my workshop did not blow although I have to hook up my 3 hp compressor on a seperate group.

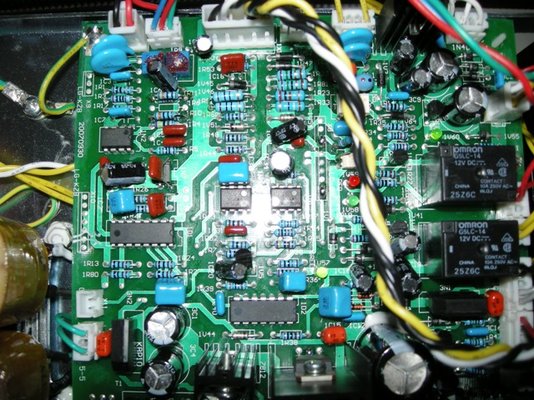

As I'am always curious what is inside these magic boxes I went ahead and opened the enclosure. Not bad. Although the quality of build is incomparable to the well known brands it seems that there has been some development the last few years. Attached some pics to give you an idea. There is some degree of integration and there are a handfull of leds indicating the status of the machine. Makes trouble shooting quite easy. Quick connectors everywhere, makes it easy to swap boards. Based on the electrical diagram and the partslist all the cutters in the range seem to use the same mainboards.

The machine is CE marked and all prints are marked ROHS.....but where is the CE certificate

?

?

Somebody in China must have been lurking on this forum, surprise......the torchconnector is now very well insulated!!!! This is not shown on the pictures on the internet so it must be a recent update (my cutter was manufactured in december 2007 according to the labels) Makes it safe now to have my daughters with me in the workshop

I was a bit surprised how small the whole thing is, I made a picture of it next to my Cebora MIG and Oerlikon Tig to give you an idea of the size.

Overall I' am not disappointed (..yet I hear some people grumble..) and time will tell if it was a wise desinvestment. If the plasmacutter is a tool that I start using regularly I can always buy something more expensive and substantial when this one dies on me.....drooling now..........

Tonight I will have some fun reading the `manual`, I´am looking forward to read paragraph 4: Description of the erection......

As I'am always curious what is inside these magic boxes I went ahead and opened the enclosure. Not bad. Although the quality of build is incomparable to the well known brands it seems that there has been some development the last few years. Attached some pics to give you an idea. There is some degree of integration and there are a handfull of leds indicating the status of the machine. Makes trouble shooting quite easy. Quick connectors everywhere, makes it easy to swap boards. Based on the electrical diagram and the partslist all the cutters in the range seem to use the same mainboards.

The machine is CE marked and all prints are marked ROHS.....but where is the CE certificate

?

?Somebody in China must have been lurking on this forum, surprise......the torchconnector is now very well insulated!!!! This is not shown on the pictures on the internet so it must be a recent update (my cutter was manufactured in december 2007 according to the labels) Makes it safe now to have my daughters with me in the workshop

I was a bit surprised how small the whole thing is, I made a picture of it next to my Cebora MIG and Oerlikon Tig to give you an idea of the size.

Overall I' am not disappointed (..yet I hear some people grumble..) and time will tell if it was a wise desinvestment. If the plasmacutter is a tool that I start using regularly I can always buy something more expensive and substantial when this one dies on me.....drooling now..........

Tonight I will have some fun reading the `manual`, I´am looking forward to read paragraph 4: Description of the erection......

)

) .

.

opend it up looks ok, well built, electronics look robust but fuses soldered to board!!!

opend it up looks ok, well built, electronics look robust but fuses soldered to board!!!