mike 109444

Member

- Messages

- 4,835

Have recently purchasedan BOC Murex Autolynx 2 as a non working machine. Machine looked to be in tidy condition but has the fault of “no welding output “ I had thought there would be plenty of info on the forum on this machine but it seams that anyone that's posted for info have not stuck around after (fixing?) there machine following getting Dave @NotANormalCoder to assist !

Did try a PM to Dave but not heard anything back yet. I have therefore carried on checking through the machine trying to figure out the fault(s).

So far :

Thoughts on thismachine so far. Machine is well built (like a tank!) Not a lot ofroom to work in it. Wiring loom very tightly bundled making following/tracing wires difficult.

Wish I had looked upthe weight of this machine before hand (seen quoted as 98Kg's)

Glad the chap I boughtit from was there to give me a hand humping it in to the back of myestate car. Would have helped if it did not still have a near full15Kg spool of wire in it !!

Only time so far I was glad that the new Skoda Octavia (hybrid) (company car) has a flat load area in theback because for work the loss of boot space due to the batteries isan absolute PITA !

Did try a PM to Dave but not heard anything back yet. I have therefore carried on checking through the machine trying to figure out the fault(s).

So far :

- Hernia moving it !

- Have sorted out some poor connections on the multi pin plugs that connect to the pcbs as these were causing wire feed etc to dropout when wriggled with torch trigger pressed.

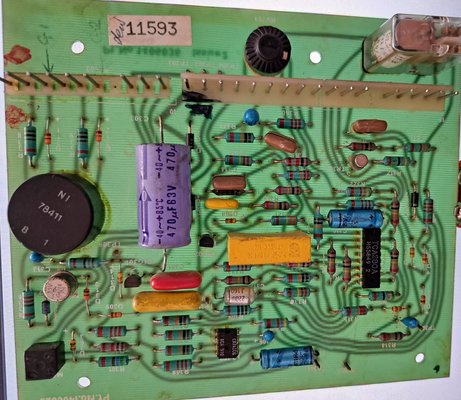

- Re-flowed some then all! Solder joints on the three pcb's

- Checked and tightened all the tag board strip connections (TB's)

- Checked and tightened the spade connections on the two link wires that feed the SCR.

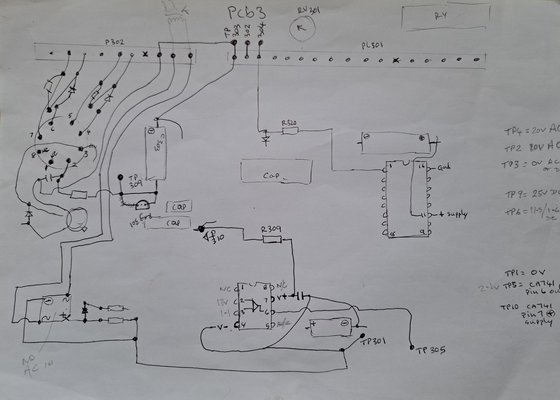

- Checked for continuity from the mains input up to and through the on/off switch to the TB connections of TB4 where it then feeds onto several areas of the machine/pcb's (still working through / working out what is feed from this).

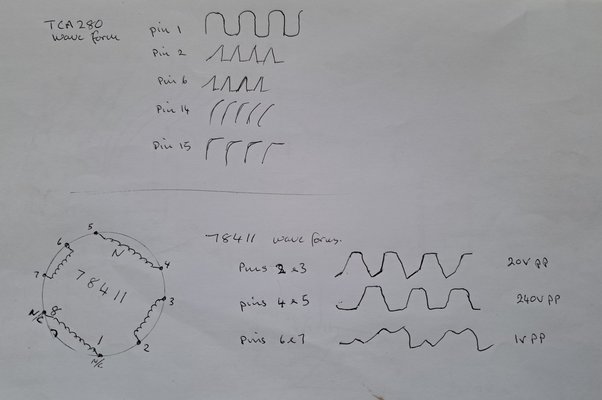

- Have previously done basic diode and turn on checks on the SCR but as I have not had to work with these devices in my normal job (they may have been present in psu's I have replaced but not needed to repair any) so have looked up how these devices are used and work. Not sure that the one in these welders is used in quite the way I have read up on apart for maybe switching on at zero crossing ?

- Noted that the SCR has a bridging strip of brass (aprox 20mm x 10mm x 2mm !) between connection 2 and 3. I have no ideal why this is !

- Have gone over the three pcb's identifying nearly all the semiconductor devices. (one transistor metal can pitted/ non readable) These include an op amp, bipolar trigger ic for triacs, quad input nand gate, atl east three 555 timers and many other devices.

- Have checked operation of any of the relays that are being feed power to there coil and all seam ok.

- Disconnected the output diodes on the heat sink and checked for shorting and basic diode checks, all ok.

- Some of the checks were done to avoid trying to fix a machine with an expensive faulty part that would rule out continuing the repairing of this machine.

Thoughts on thismachine so far. Machine is well built (like a tank!) Not a lot ofroom to work in it. Wiring loom very tightly bundled making following/tracing wires difficult.

Wish I had looked upthe weight of this machine before hand (seen quoted as 98Kg's)

Glad the chap I boughtit from was there to give me a hand humping it in to the back of myestate car. Would have helped if it did not still have a near full15Kg spool of wire in it !!

Only time so far I was glad that the new Skoda Octavia (hybrid) (company car) has a flat load area in theback because for work the loss of boot space due to the batteries isan absolute PITA !