Hi all,

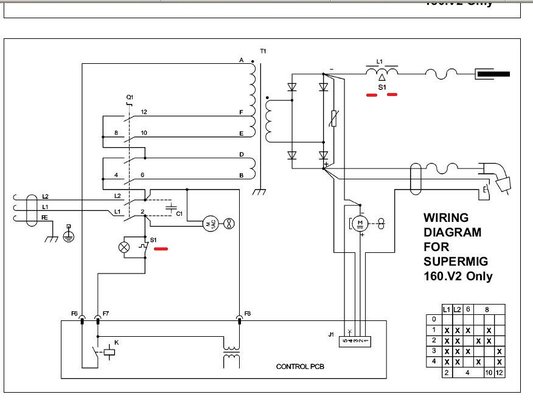

Been building up a MIG welder, its a bit of a mix of parts but should all work fine, the point I'm stuck on now is temperature regulation. The overall design I'm using as a basis uses a thermostat to control the temperature by cutting the torch trigger signal, which seems a reasonably sensible method, but since its all based on a wiring diagram I cant really tell much, mainly what temperature the thermostat triggers at (even after a bit of looking around), and where exactly its located in the case. So since I'm doing this from scratch, where do you guys think a sensible location would be? (A brief look around suggests maybe they are attached to the main transformer, I think on the core?) Would also be nice to know what sort of temperature range welder thermostats tend to trigger at so I can source a decent one to use. Or even info about alternative methods of regulating temperature if any exist and are any good?

Thanks!

Edit : Should probably point out its a 220A welder, and running on single phase power. It probably shouldn't matter, since stuff will fail at similar temperatures regardless of power rating, but cant hurt to list it.

Been building up a MIG welder, its a bit of a mix of parts but should all work fine, the point I'm stuck on now is temperature regulation. The overall design I'm using as a basis uses a thermostat to control the temperature by cutting the torch trigger signal, which seems a reasonably sensible method, but since its all based on a wiring diagram I cant really tell much, mainly what temperature the thermostat triggers at (even after a bit of looking around), and where exactly its located in the case. So since I'm doing this from scratch, where do you guys think a sensible location would be? (A brief look around suggests maybe they are attached to the main transformer, I think on the core?) Would also be nice to know what sort of temperature range welder thermostats tend to trigger at so I can source a decent one to use. Or even info about alternative methods of regulating temperature if any exist and are any good?

Thanks!

Edit : Should probably point out its a 220A welder, and running on single phase power. It probably shouldn't matter, since stuff will fail at similar temperatures regardless of power rating, but cant hurt to list it.

Last edited:

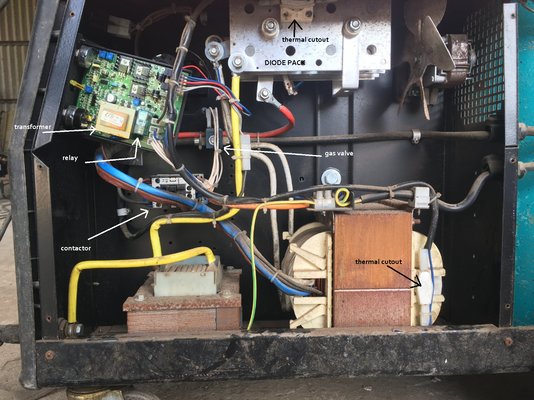

). There is also a thermistor on the rectifier bridging one of the diodes, its still on but I'm planning on getting rid of it since as far as I can see its just so the board can measure the heat of the rectifier, since there doesn't seem to be any way for it to cut power if it gets too hot. Since my new (to me) board cant do anything with this I'm just going to ditch it , shouldn't cause any problems as far as I can see. As for the thermostat on the choke, is this a decent location to leave it? I would have thought it would be better on the main transformer since that's the most expensive bit to replace, but I guess the currents going through both so both are going to heat up at the same time? As for the wire feed, the units plastic for the most part, but seems to feed smoothly enough, might get in there and give it a clean up though.

). There is also a thermistor on the rectifier bridging one of the diodes, its still on but I'm planning on getting rid of it since as far as I can see its just so the board can measure the heat of the rectifier, since there doesn't seem to be any way for it to cut power if it gets too hot. Since my new (to me) board cant do anything with this I'm just going to ditch it , shouldn't cause any problems as far as I can see. As for the thermostat on the choke, is this a decent location to leave it? I would have thought it would be better on the main transformer since that's the most expensive bit to replace, but I guess the currents going through both so both are going to heat up at the same time? As for the wire feed, the units plastic for the most part, but seems to feed smoothly enough, might get in there and give it a clean up though. )

)