You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mig gas nozzel worklive

- Thread starter sechy

- Start date

- Messages

- 17,485

pedrobedro

Man at Matalan

- Messages

- 13,073

- Location

- CX near Chesterfield

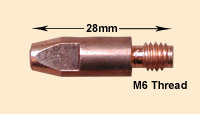

Not cleaning out the gas shroud often enough ruins a few tips. Part number 1 is the tip and number 2 is the gas shroud Sechy.

I will precise my question. In intensive and continuous welding is gas shroud /part2/ getting overheating in which the insulation can not sustain and get an electric shock?

The gas shroud can certainly overheat a bit and suffer damage at the end, hence the need for occasional replacement, but I would not expect it to start glowing red hot or disintegrate during use, unless perhaps the amps/power used were far above the stated amperage rating for the torch.

As for an electric shock, MIG welding voltage is typically about 20 volts, and would not normally give a shock, epecially through all the plastic of a MIG torch handle and gloved hands.

Is your question hypothetical, like 'what if?' or has the situation actually occurred? If so, what equipment, settings and situation?

I hope I've understood your question correctly.

Dear GeorgeB,

First, I as a new in the forum I'm surprised how quickly and how responsive are all and congratulate you for Christmas and New Year 2010. I am particularly interested in whether the insulation plate located between the inner brass collar and outer copper collar parts of the gas shroud does not lose its insulating properties when a welder intensive and continuous, for example 2 hours, works. And if such a problem exist is it not reason to scrap the gas shroud? My main question essentially is:Is there really such a problem with the proposed market gas shrouds?

First, I as a new in the forum I'm surprised how quickly and how responsive are all and congratulate you for Christmas and New Year 2010. I am particularly interested in whether the insulation plate located between the inner brass collar and outer copper collar parts of the gas shroud does not lose its insulating properties when a welder intensive and continuous, for example 2 hours, works. And if such a problem exist is it not reason to scrap the gas shroud? My main question essentially is:Is there really such a problem with the proposed market gas shrouds?

pedrobedro

Man at Matalan

- Messages

- 13,073

- Location

- CX near Chesterfield

It's not a problem if you don't let it happen sechy. The spatter inside the nozzle can conduct the electricity from the tip and if you touch the nozzle to the work while you are welding it will melt a piece out of it when it arcs. This is not the fault of the insulation which I must say I have never known one of mine to fail but other people may have different experience. Tip Dip is the usual answer but I have never used it myself I just clean inside the nozzle with a blunt screwdriver. If you scrap the gas shroud/nozzle what will keep the gas around the weld pool to shield it unless you go to flux core and then you can use a gasless shroud. If you mean reason to scrap the one which is faulty and replace it with a new one then you are right it is the only answer to replace it.

Last edited:

- Messages

- 17,485

Now I think I understand you.

If I am correct, you are saying that the shroud/nozzle will create a spark if it comes into contact with the item you are welding?

If this is correct then you require a new nozzle as the insulation is probably damaged by spatter.

Regarding the overheating, George could also be correct in that the torch may not be the correct type for the machine and the type of welding you are doing.

If it is overheating then this suggests that either the torch has an internal fault or that you need to use a bigger torch than the one you are currently using.

What machine are you using, what type of torch and what sort of power are you running it at please?

If I am correct, you are saying that the shroud/nozzle will create a spark if it comes into contact with the item you are welding?

If this is correct then you require a new nozzle as the insulation is probably damaged by spatter.

Regarding the overheating, George could also be correct in that the torch may not be the correct type for the machine and the type of welding you are doing.

If it is overheating then this suggests that either the torch has an internal fault or that you need to use a bigger torch than the one you are currently using.

What machine are you using, what type of torch and what sort of power are you running it at please?

Dave Richards

Member

- Messages

- 15

insulators in the shroud do break down. just replace the shroud.

chunkolini

celebrity artiste

- Messages

- 9,580

- Location

- Swansea

Sechy

I have burned out the insulator on a few shrouds by long periods of welding. You have to be doing a lot of welding but it can hapen. The only solution is to rerplace the shroud when this happens.

Or if you have a welder with a removeable torch buy a higher rated torch, the construction of the shroud is more durable.

Chunko'.

I have burned out the insulator on a few shrouds by long periods of welding. You have to be doing a lot of welding but it can hapen. The only solution is to rerplace the shroud when this happens.

Or if you have a welder with a removeable torch buy a higher rated torch, the construction of the shroud is more durable.

Chunko'.