Josh hector

New Member

- Messages

- 16

- Location

- Bournemouth, uk

Hi guys, my first post on here but I've been a long time reader on some of the more interesting things I get linked to from other forums I use.

I've just purchased for a grand total of £50 this old heavy mig welder. It's 120a and has a euro torch and it is a heavy old monster. After some googling I've found two posts on separate forums about this welder but both turn out to be the same unit that has changed hands. I have raised my queries with both other members but am posting here as most of you guys are bound to be more experienced in matters such as this.

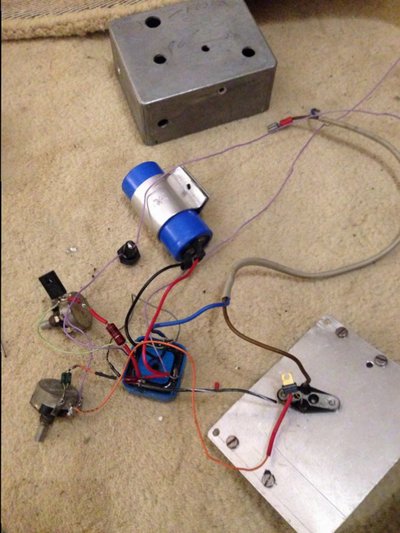

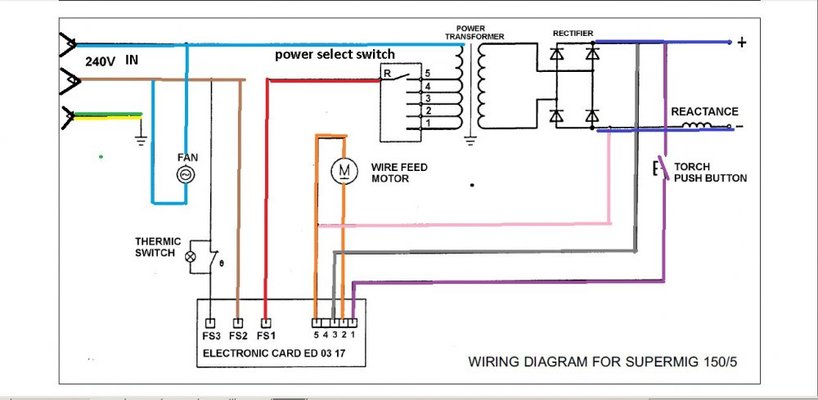

The welder has been played with before in what I assume to be an attempt at getting the wire feed more accurate. It has had a box of "tricks" attached to the back of the pot and the stitch timer removed completely as far as I can tell. I simply would like to get the wire feed potentiometer back to standard and the fuse and power leds wired back in properly instead of all this "stuff" as it's creating a weird motor reset/short.

I have attached images of the welder and the stuff someone has wired in. I studied design engineering and am remotely capable with a soldering iron etc but I was just wondering if there was a simple way using the three wires off the back of the pot to get this sorted.

I've just purchased for a grand total of £50 this old heavy mig welder. It's 120a and has a euro torch and it is a heavy old monster. After some googling I've found two posts on separate forums about this welder but both turn out to be the same unit that has changed hands. I have raised my queries with both other members but am posting here as most of you guys are bound to be more experienced in matters such as this.

The welder has been played with before in what I assume to be an attempt at getting the wire feed more accurate. It has had a box of "tricks" attached to the back of the pot and the stitch timer removed completely as far as I can tell. I simply would like to get the wire feed potentiometer back to standard and the fuse and power leds wired back in properly instead of all this "stuff" as it's creating a weird motor reset/short.

I have attached images of the welder and the stuff someone has wired in. I studied design engineering and am remotely capable with a soldering iron etc but I was just wondering if there was a simple way using the three wires off the back of the pot to get this sorted.