Having not found a build thread on here for one of these I thought I'd do one incase anyone is in the market for one.

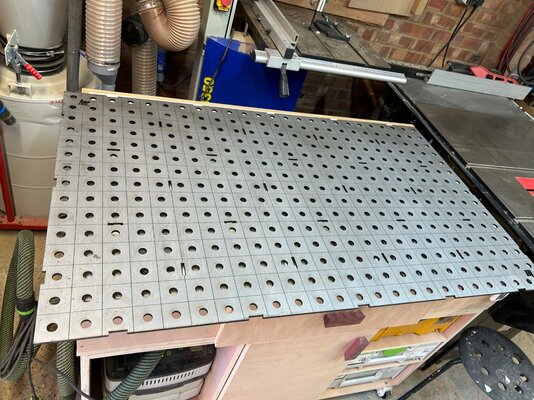

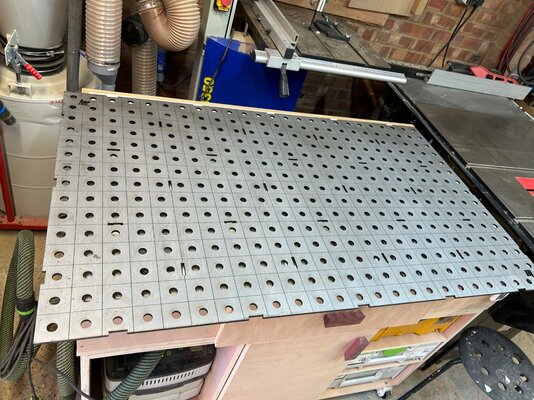

I bought a 1250mm x 750mm Midipro table from Mac industries direct in kit form with no legs or castors.

This is the same Tables sold by R-tech.

I collected the table direct from them which turned out to be helpful as I think. I turned up a bit early for them and they hadn't finished prepping the table fully so some of the cutouts on the cross members were still in place where the laser cutter hadn't quite got them fully. Iended up using thesewith holes drilled in them and clamping brackets.

Mac do sell little plates that can be used for assembly but I didnt buy them opting to make my own once I got it home.

The table is pretty simple to assemble with little to no instructions you just need to be careful to make sure you clamp it down well enough to not leave gaps at any joints. I think you cant have too many clamps

So armed with a load of threaded rod and a b inch of M10 coach bolt I went to town clamping this thing down to try and get it as flat as possible.

The cut outs that were left in the cross members got some holes drilled into them and used at the middle portions and the corners.

One thing I did lack at this point though was enough clamps to also clamp the edges. So I Tacked the centres after giving it a clean down to remove any residue and them moved the clamps around the edge to tack the edges.

I made a mistake by leaving the corner leg plates off so I could weld in the corners which meant I could not get the plates to fit! I had to cut the corner welds open to allow me room to get them in and welded in place. I'm not worried about those welds I cut though as the corners are lined up better now that they were without. Lesson learned.

Once I was all tacked I went round it with my best square and straight edge to check it was flat and not twisted. As far as I can tell it's pretty good. Mac dont list a tolerance for flatness only a hole tolerance so I have no idea how good a job I did compared to if I had got them to make it for me.

Flipped upside down again I ran proper welds along all the tabs to finish the weld off.

Mac's website says that after taking it you flip it over and weld up the tab interfaces but I think they originally when they wrote that guide cut the tabs differently with a small recess in them to allow the weld to go into. Now the tabs are square so and welding on the surface is going to require significant flattening down afterwards.

Onto the legs.

Again I opted to make my own. Using 40x40 x 2.5mm Box section I made up a simple frame which will allow me somewhere to store suff in the future once I decide what I want under there.

My legs on levelling castors seems very strong and I have to wonder if the 70x70 versions they supply are perhaps a bit overkill on a table this size. On a 10mm thick table twice the size, then yes but not on this one.

And thats it. All done and ready to be used so I no longer burn holes in my woodworking bench.

Moving forward I think it would be nice if Mac made some side skirt extensions to widen the table. For the heavier duty tables you can get them but if you could say get 1m x 250mm extensions I could make the table 1250mm square which I think would be a nice size depending on the job.

If you found this useful then awesome. If not then please me kind. Still new to welding and my R-tech 181 was flat out with the welding amps so if the welding doesnt look as good as it could be then thats my excuse ha!

I bought a 1250mm x 750mm Midipro table from Mac industries direct in kit form with no legs or castors.

This is the same Tables sold by R-tech.

I collected the table direct from them which turned out to be helpful as I think. I turned up a bit early for them and they hadn't finished prepping the table fully so some of the cutouts on the cross members were still in place where the laser cutter hadn't quite got them fully. Iended up using thesewith holes drilled in them and clamping brackets.

Mac do sell little plates that can be used for assembly but I didnt buy them opting to make my own once I got it home.

The table is pretty simple to assemble with little to no instructions you just need to be careful to make sure you clamp it down well enough to not leave gaps at any joints. I think you cant have too many clamps

So armed with a load of threaded rod and a b inch of M10 coach bolt I went to town clamping this thing down to try and get it as flat as possible.

The cut outs that were left in the cross members got some holes drilled into them and used at the middle portions and the corners.

One thing I did lack at this point though was enough clamps to also clamp the edges. So I Tacked the centres after giving it a clean down to remove any residue and them moved the clamps around the edge to tack the edges.

I made a mistake by leaving the corner leg plates off so I could weld in the corners which meant I could not get the plates to fit! I had to cut the corner welds open to allow me room to get them in and welded in place. I'm not worried about those welds I cut though as the corners are lined up better now that they were without. Lesson learned.

Once I was all tacked I went round it with my best square and straight edge to check it was flat and not twisted. As far as I can tell it's pretty good. Mac dont list a tolerance for flatness only a hole tolerance so I have no idea how good a job I did compared to if I had got them to make it for me.

Flipped upside down again I ran proper welds along all the tabs to finish the weld off.

Mac's website says that after taking it you flip it over and weld up the tab interfaces but I think they originally when they wrote that guide cut the tabs differently with a small recess in them to allow the weld to go into. Now the tabs are square so and welding on the surface is going to require significant flattening down afterwards.

Onto the legs.

Again I opted to make my own. Using 40x40 x 2.5mm Box section I made up a simple frame which will allow me somewhere to store suff in the future once I decide what I want under there.

My legs on levelling castors seems very strong and I have to wonder if the 70x70 versions they supply are perhaps a bit overkill on a table this size. On a 10mm thick table twice the size, then yes but not on this one.

And thats it. All done and ready to be used so I no longer burn holes in my woodworking bench.

Moving forward I think it would be nice if Mac made some side skirt extensions to widen the table. For the heavier duty tables you can get them but if you could say get 1m x 250mm extensions I could make the table 1250mm square which I think would be a nice size depending on the job.

If you found this useful then awesome. If not then please me kind. Still new to welding and my R-tech 181 was flat out with the welding amps so if the welding doesnt look as good as it could be then thats my excuse ha!