Kram

Member

- Messages

- 7,700

- Location

- Sussex

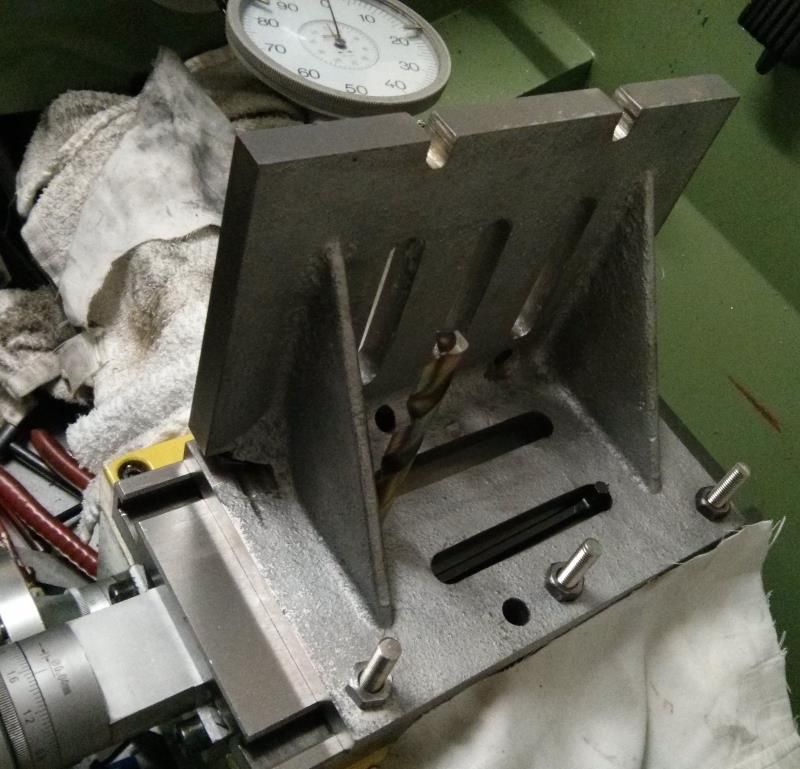

Interested to know what anyone else uses to clamp work up for milling. I cut up and drilled a few scraps of 5mm mild steel.. not much good - they all bent! So need to make some more, and some parallels.

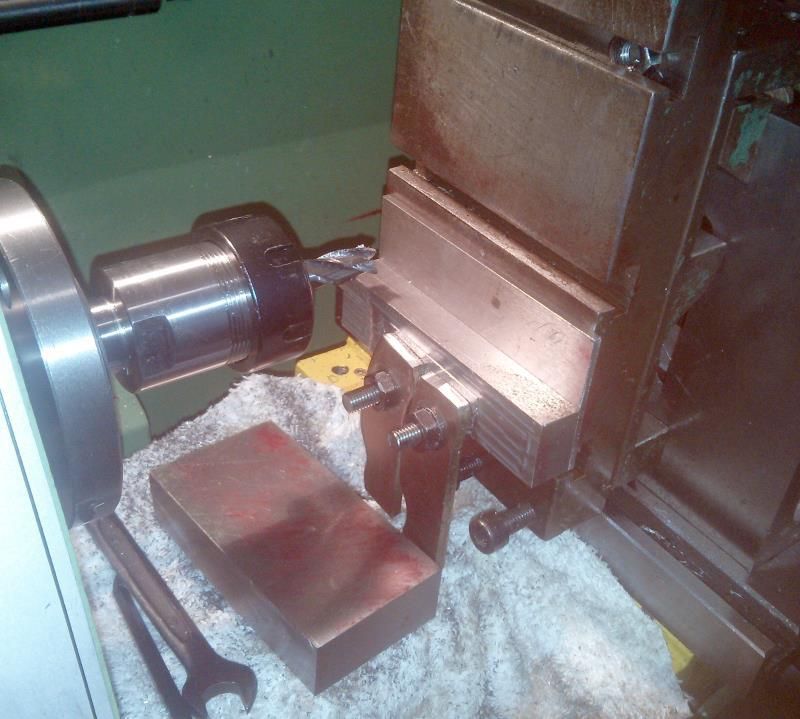

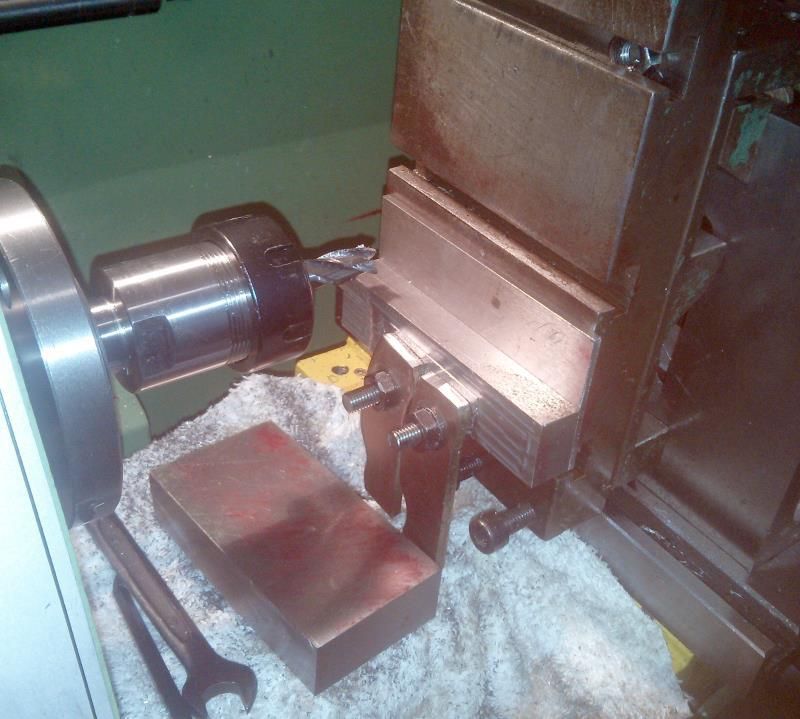

Decided to drill and tap some holes in the vertical slide, using the lower T slot wastes a bit of travel.. So now I can clamp a bit lower. I got a lump of tool steel off ebay, so I made vice jaw to bolt on. Took an hour to hacksaw through it and carbide cutter to get it flat.

I guess a fly cutter would give a better finish, so that might be next job.

Decided to drill and tap some holes in the vertical slide, using the lower T slot wastes a bit of travel.. So now I can clamp a bit lower. I got a lump of tool steel off ebay, so I made vice jaw to bolt on. Took an hour to hacksaw through it and carbide cutter to get it flat.

I guess a fly cutter would give a better finish, so that might be next job.

I'd like to keep 2mm pitch, so either 10mm or 16mm diameter

I'd like to keep 2mm pitch, so either 10mm or 16mm diameter