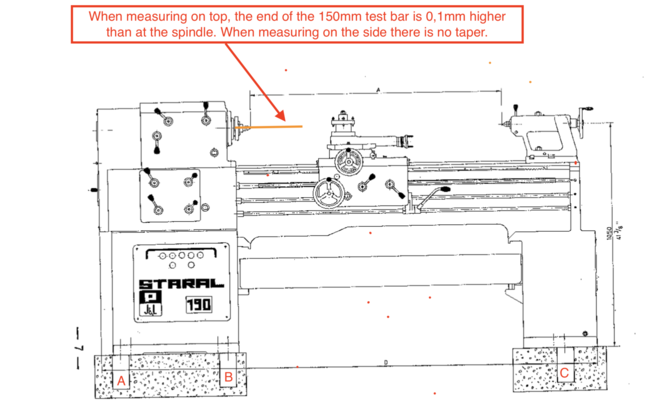

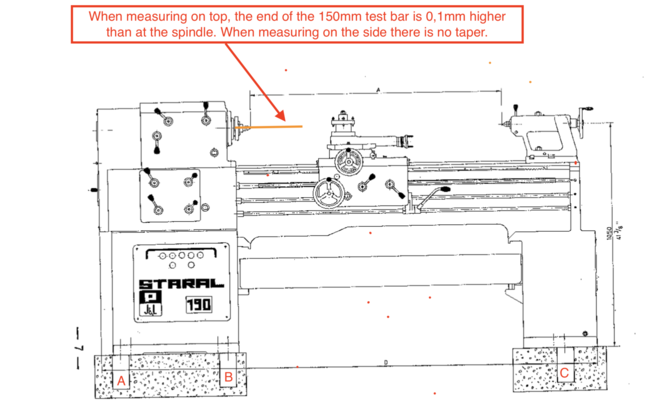

Having problems getting the spindle parallel with the bed on my lathe, the bed/ways themselves are level (measured with a 0,35mm/1000mm bubble level), but can't seem to get the spindle axis parallel with the bed.

See the sketch below, I have a 200mm MT5 precision ground test bar (orange stripe on the sketch) that goes straight into the spindle taper, when i measure runout with the dial gauge measuring of the side of the bar i get barely any movement in the dial gauge needle, when i spin the spindle around there is also no movement in the dial gauge needle. If i then measure with the dial gauge needle on top of the test bar there is a 0,12mm difference in about 150mm of travel, so at the spindle the dial gauge reads 0, if i then move the carriage 150mm away it reads 0,12.

I tried levelling/tilting the headstock using the levelling feet on the lathe (marked A, B and C on the sketch) but the lathe is so rigid that if I come up on feet A it just picks up feet B off of the concrete, so the head stock does not tilt levelling out the spindle axis to the bed axis.

Any advice?

See the sketch below, I have a 200mm MT5 precision ground test bar (orange stripe on the sketch) that goes straight into the spindle taper, when i measure runout with the dial gauge measuring of the side of the bar i get barely any movement in the dial gauge needle, when i spin the spindle around there is also no movement in the dial gauge needle. If i then measure with the dial gauge needle on top of the test bar there is a 0,12mm difference in about 150mm of travel, so at the spindle the dial gauge reads 0, if i then move the carriage 150mm away it reads 0,12.

I tried levelling/tilting the headstock using the levelling feet on the lathe (marked A, B and C on the sketch) but the lathe is so rigid that if I come up on feet A it just picks up feet B off of the concrete, so the head stock does not tilt levelling out the spindle axis to the bed axis.

Any advice?