brewdexta

The biggest tool in the box

- Messages

- 5,756

- Location

- UK

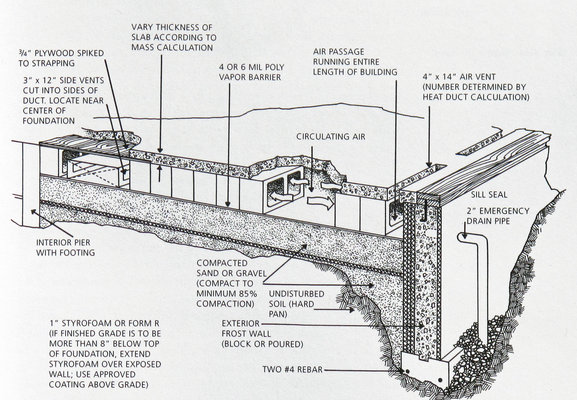

My workshop is on the first floor, it is made of concrete poured into Kingspan Multideck, i.e. a corrugated steel pan with rebar and mesh in it and about 5" concrete like this.

The surface is relatively smooth but not like a babies bum, we poured it in winter up in the Pennines before the sides and roof were on. We did have big floats but of course it rained. It is painted with cheap floor paint that has seen better days.

The walls and roof are 50mm Kingspan insulated panels and if all goes well, the workshop will be heated soon. Floor area is 20m x 6m so need to get it right!

As the floor is a bit scabby and uninsulated and I don't fancy scrabbling the old paint off to put on epoxy, I was wondering if this idea is good or barking.

Put down Kingspan/cellotex type insulation, somewhere between 25 and 30mm, then cover it with 22mm moisture resistant chipboard T&G flooring or OSB or similar. Anywhere with point loads like lathe, bench or mill feet will have steel plates underneath the feet to spread the load. I can raise the steel workshop door about 30mm and it has a 20mm threshold so can get away with raising the floor by about 50mm, I haven't measured it yet.

The floor would then be covered with some kind of laminate or hard-wearing industrial plastic, maybe like this if I can find some sensibly priced, I have done before when we owned a retail shop.

Will use some kind of weld spatter resistant flooring near the welding bench. Probably chequer plate plus put some sheets of hardboard or similar and/or screens around the periphery if doing something big. I don't do a lot of welding so not too much of a pain.

Cheers

Andy

The surface is relatively smooth but not like a babies bum, we poured it in winter up in the Pennines before the sides and roof were on. We did have big floats but of course it rained. It is painted with cheap floor paint that has seen better days.

The walls and roof are 50mm Kingspan insulated panels and if all goes well, the workshop will be heated soon. Floor area is 20m x 6m so need to get it right!

As the floor is a bit scabby and uninsulated and I don't fancy scrabbling the old paint off to put on epoxy, I was wondering if this idea is good or barking.

Put down Kingspan/cellotex type insulation, somewhere between 25 and 30mm, then cover it with 22mm moisture resistant chipboard T&G flooring or OSB or similar. Anywhere with point loads like lathe, bench or mill feet will have steel plates underneath the feet to spread the load. I can raise the steel workshop door about 30mm and it has a 20mm threshold so can get away with raising the floor by about 50mm, I haven't measured it yet.

The floor would then be covered with some kind of laminate or hard-wearing industrial plastic, maybe like this if I can find some sensibly priced, I have done before when we owned a retail shop.

Will use some kind of weld spatter resistant flooring near the welding bench. Probably chequer plate plus put some sheets of hardboard or similar and/or screens around the periphery if doing something big. I don't do a lot of welding so not too much of a pain.

Cheers

Andy