Tangledfeet

Knurling is my Nemesis.

- Messages

- 3,201

- Location

- Top of a hill above St Andrews, Fife

We have two Warco GH1330 lathes at school so limited to 16mm shank tool holders. As much as I suspect HSS tooling would be more robust, the workshop doesn't have a bench grinder so couldn't sharpen them; so have to use tools with CNMG090304 inserts.

The wee CNMG inserts take a battering and regularly come off the tool holders, fortunately the kids are pretty good about finding them but I have no more spare inserts now.

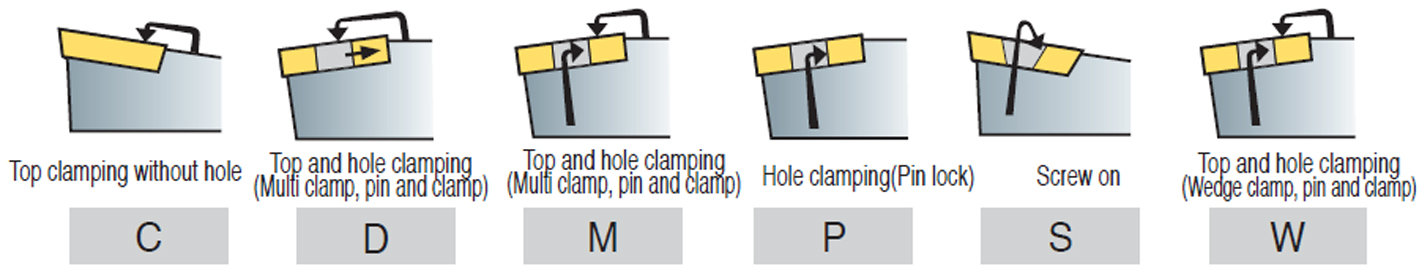

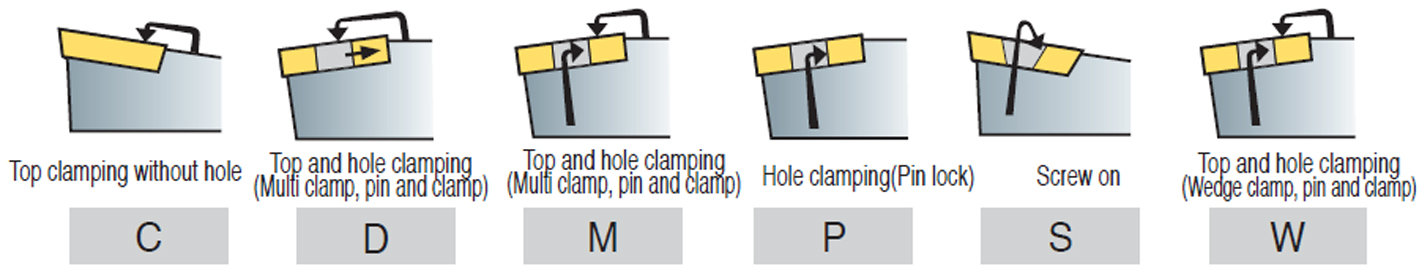

I've been looking online at the likes of Cutwel for alternative tool holders that use the top or top and hole method:

In people's experiences are these methods more robust that the type P tools we have?

Alas it seems that most top clamp type tools start at 20mm which is no good for the lathes we have, the only one I've found would be this one from Engineering Supplies:

Would these three-sided inserts perhaps also be more robust? I've tried to get away from turning steel unless we absolutely have to as we don't have coolant (discussed previously!) and and I can use aluminium round bar for the vast majority of tasks.

Insert tooling is, amongst many things, I know very little about and have no more than the experiences I've had with the 16mm holders and CNMG inserts above so any help much appreciated!

If I can come up with a case that new tool holders and different inserts would be the way to go I might be able to get approval to buy some; none of the suppliers on the council's purchasing scheme so we'd have to pay VAT thus increasing cost.

Cheers!

The wee CNMG inserts take a battering and regularly come off the tool holders, fortunately the kids are pretty good about finding them but I have no more spare inserts now.

I've been looking online at the likes of Cutwel for alternative tool holders that use the top or top and hole method:

In people's experiences are these methods more robust that the type P tools we have?

Alas it seems that most top clamp type tools start at 20mm which is no good for the lathes we have, the only one I've found would be this one from Engineering Supplies:

DWLNR 1616 H06 (95Deg) Top Clamp Toolholder - engineeringsupplies.co.uk

distributors of quality & performance carbide inserts, toolholders, boring bars, drills, milling cutters, taps, reamers and other engineering consumables.

www.engineeringsupplies.co.uk

Would these three-sided inserts perhaps also be more robust? I've tried to get away from turning steel unless we absolutely have to as we don't have coolant (discussed previously!) and and I can use aluminium round bar for the vast majority of tasks.

Insert tooling is, amongst many things, I know very little about and have no more than the experiences I've had with the 16mm holders and CNMG inserts above so any help much appreciated!

If I can come up with a case that new tool holders and different inserts would be the way to go I might be able to get approval to buy some; none of the suppliers on the council's purchasing scheme so we'd have to pay VAT thus increasing cost.

Cheers!