You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

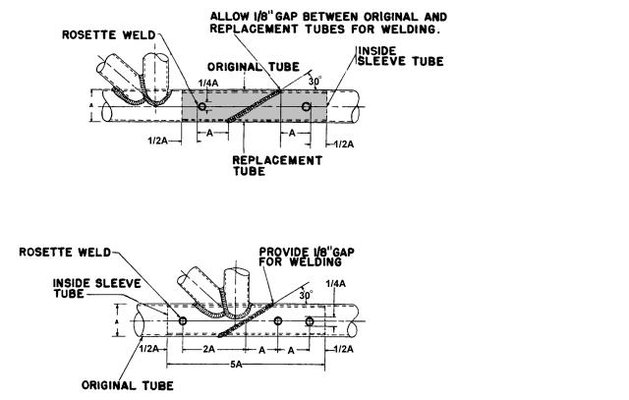

Inner. Sleeve in tube

- Thread starter Oppet

- Start date

and those tubes are different wall thickness, so would be impossible to make sleeve in lathe.

and those tubes are different wall thickness, so would be impossible to make sleeve in lathe.