You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Inlet manifolds

- Thread starter simon718

- Start date

Unclefista

Member

- Messages

- 170

I've fitted CBR600 carbs to my 1.8 zetec using mild steel for a manifold

I used some 8mm plate for the flange that I chain drilled and filed (never, ever again), and mild steel tube MIG welded to it.

The most expensive bit was the silicone hose to join the carbs to the manifold. The whole lot was done for less than £50, luckily I already had a megajolt for sparks.

The difference between the old Weber carb and the bike carbs is night and day, all I've done to the carbs is drill the main jets out a bit and it's run beautifully over the last few thousand miles.

I've hosted a file with the Honda CBR workshop manual carb specific parts on my webspace, it came in handy when I was fettling

http://www.locost.pwp.blueyonder.co.uk/stuff/cbr600carbs.rar

I used some 8mm plate for the flange that I chain drilled and filed (never, ever again), and mild steel tube MIG welded to it.

The most expensive bit was the silicone hose to join the carbs to the manifold. The whole lot was done for less than £50, luckily I already had a megajolt for sparks.

The difference between the old Weber carb and the bike carbs is night and day, all I've done to the carbs is drill the main jets out a bit and it's run beautifully over the last few thousand miles.

I've hosted a file with the Honda CBR workshop manual carb specific parts on my webspace, it came in handy when I was fettling

http://www.locost.pwp.blueyonder.co.uk/stuff/cbr600carbs.rar

simon718

needs to stay off ebay

- Messages

- 1,985

I've fitted CBR600 carbs to my 1.8 zetec using mild steel for a manifold

I used some 8mm plate for the flange that I chain drilled and filed (never, ever again), and mild steel tube MIG welded to it.

The most expensive bit was the silicone hose to join the carbs to the manifold. The whole lot was done for less than £50, luckily I already had a megajolt for sparks.

The difference between the old Weber carb and the bike carbs is night and day, all I've done to the carbs is drill the main jets out a bit and it's run beautifully over the last few thousand miles.

I've hosted a file with the Honda CBR workshop manual carb specific parts on my webspace, it came in handy when I was fettling

http://www.locost.pwp.blueyonder.co.uk/stuff/cbr600carbs.rar

hi there Unclefista was hoping you would drop in, saw a few posts by yourself on another forum and thought u would be the man to ask

due to this not exactly being the flashest car ever

(to say the least) i think i will stick with m/s - cant see the car still being on the road or having this engine long enough to rot through m/s

(to say the least) i think i will stick with m/s - cant see the car still being on the road or having this engine long enough to rot through m/s

however, have just found this site, and looking at the 1600 90PS section they don't make it sound worth it to try making this engine quicker due to the smallness of the valves

either way, looks like a bit of ebay scouring is necessary to get all the parts, and possibly a 2.0 engine

Unclefista

Member

- Messages

- 170

due to this not exactly being the flashest car ever(to say the least)

Sounds like my kind of car

I bought my Zetec for £50 on ebay (although I got lots of other bits thrown in), you're looking at a lot more than that for a 2 litre. If you get the 115ps 1.8 from the XR3i (fitted to others too) you only need a set of 2 litre cams to make 4-5hp less than the standard 2 litre.

So you end up with a sweeter revving engine with almost no difference in power

My car budget is severely limited, the only reason I could afford to change the engine is the £200 a mad ebay man drove a 350 miles round trip to give me for my old worn out and smoking crossflow

simon718

needs to stay off ebay

- Messages

- 1,985

Sounds like my kind of car

what do you reckon to the carbs on a 1.6 then, waste of time? wouldn't mind doing an engine swap but any work is going to be done on my drive (fun

) have been looking at engines on ebay, i reckon i could get a 2.0 for 250-300 on there but it will involve a trip to england/scotland with the van. will have to have a ring round the local breakers

) have been looking at engines on ebay, i reckon i could get a 2.0 for 250-300 on there but it will involve a trip to england/scotland with the van. will have to have a ring round the local breakers1.8 with 2.0 cams sounds like an option, i see the purchase/lashing together of a shed for the front garden coming on to build an engine

the fella that bought the x-flow, was he slightly lacking

thanks for your advice mate

pete, thanks as well, i was just a bit worried as nearly every custom inlet i'd seen was alu

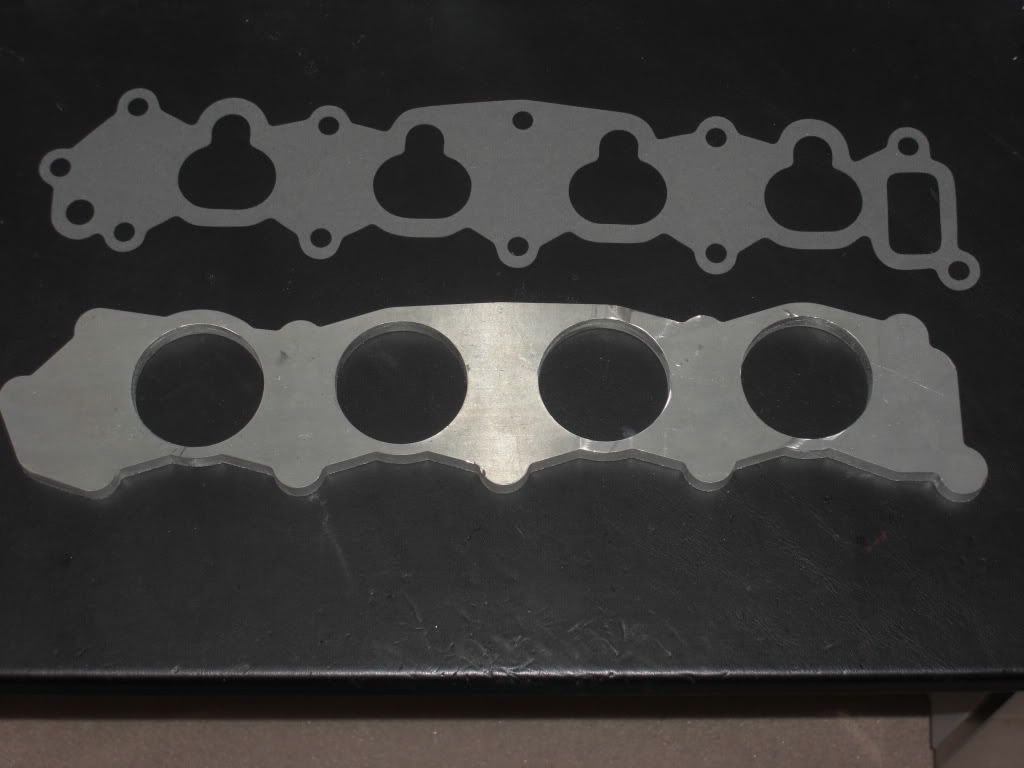

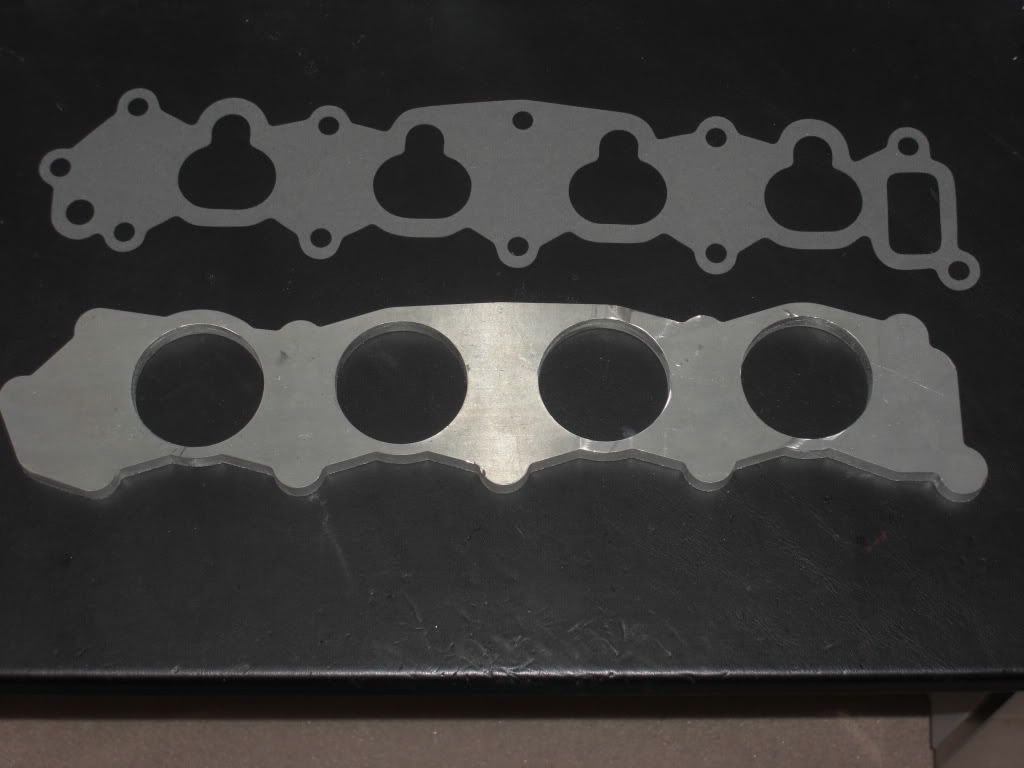

If your intake port is anything like your throttle body exit, you could do this:

have the flange machined to take the bodies and glue them in.

This one is for a Suzuki 1600 head, needs very little in the way of port matching, to essentially make a set of direct to head bodies. Gives plenty of scope to alter the induction length/shape to my hearts content. These are some sort of GSXR taper bodies, don't know which one though.

iain

have the flange machined to take the bodies and glue them in.

This one is for a Suzuki 1600 head, needs very little in the way of port matching, to essentially make a set of direct to head bodies. Gives plenty of scope to alter the induction length/shape to my hearts content. These are some sort of GSXR taper bodies, don't know which one though.

iain

Pete.

Forum Supporter

- Messages

- 15,068

- Location

- Kent, UK

These are some sort of GSXR taper bodies, don't know which one though.

iain

I think the 600 uses 38mm and the 1000 has 42mm throttle bodies. Dunno about the 750.

the 750 K1 and K2 are identical to the 1000 K1 and K2 i beleive...

80mm spacing and taper from 42 to 48 mm......

also madzuki- the flange that those bodies are fitted onto.. does that bolt straight to the head??

from reading a few sites... the jenvey one especially i was lead to beleive that the distance from the valve face to the butterfly is as important as the distance from the butterfly to the open end of the inlet trumpet??

from jenvey site:

A practical minimum figure for a 7 - 9,000 RPM engine is 200mm,

80mm spacing and taper from 42 to 48 mm......

also madzuki- the flange that those bodies are fitted onto.. does that bolt straight to the head??

from reading a few sites... the jenvey one especially i was lead to beleive that the distance from the valve face to the butterfly is as important as the distance from the butterfly to the open end of the inlet trumpet??

from jenvey site:

A practical minimum figure for a 7 - 9,000 RPM engine is 200mm,

the 750 K1 and K2 are identical to the 1000 K1 and K2 i beleive...

80mm spacing and taper from 42 to 48 mm......

also madzuki- the flange that those bodies are fitted onto.. does that bolt straight to the head??

from reading a few sites... the jenvey one especially i was lead to beleive that the distance from the valve face to the butterfly is as important as the distance from the butterfly to the open end of the inlet trumpet??

from jenvey site:

A practical minimum figure for a 7 - 9,000 RPM engine is 200mm,

Yes, it will do when I get round to drilling the plate, gotten sidetracked at the moment. This head is only SOHC, with a weird tappet arrangement, so it's going to be 7000 max, but it's fairly close to 200mm. Probably going to use an insulator plate and trim that to change the shape from the bodies to the head, that should give me another 10-20mm, depending on how it measures out exactly and what space I have. Probably going into my Swift first, then into a Mini my son and I are building, which is why we want to take up as little space as possibly and use trumpets to tune the torque.

The spacing is almost identical to the head I'm using, but I'm going to add a little bead of weld to the actuator fingers, then grind down, just to be on the safe side.

Pete, These are 46mm taper bodies, going down to 40mm

iain

ahhh the joys of FWD and tiny engine bays...

i have a similar problem with my 106 unfortunatly do to the random port spacings on my 8v head OO OO as opposed to O O O O i have to have a bit of tube to get the tracts evenly spaced..

a bit of scuttle panel removal and swapping from RHD to LHD wiper setup has bought me a few inches....

i have a similar problem with my 106 unfortunatly do to the random port spacings on my 8v head OO OO as opposed to O O O O i have to have a bit of tube to get the tracts evenly spaced..

a bit of scuttle panel removal and swapping from RHD to LHD wiper setup has bought me a few inches....