You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

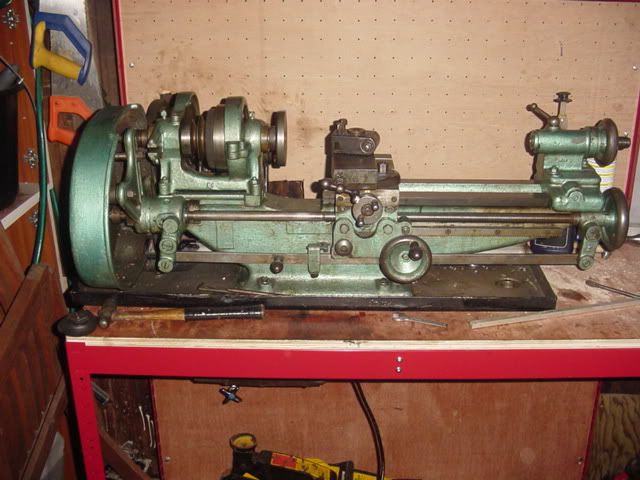

Identifying a lathe?

- Thread starter Rich H

- Start date

Pete.

Forum Supporter

- Messages

- 15,068

- Location

- Kent, UK

Yes it's a Drummond M, as identified by the toolpost. They were made by Myford after a certain year - it was forced on Drummond by some government department to do with the war effort. The bar hanging along the bottom is a carriage-feed knock-off. My father has a similar machine which he bought recently with loads of accessories including a nice Burnerd 4-jaw, two different collet chuck systems, a compound vertical slide and a pair of 127-tooth metric transposing gears. His was missing the aforementioned bar though.

Pete.

Forum Supporter

- Messages

- 15,068

- Location

- Kent, UK

Sounds like a good buy, I was impressed by the sturdiness of the machine - much better than my similar-sized Atlas. They don't look too rigid in the pictures with the single foot and long overhanging tail-end but I think they are a great machine for the size & weight. look after the headstock bearings.

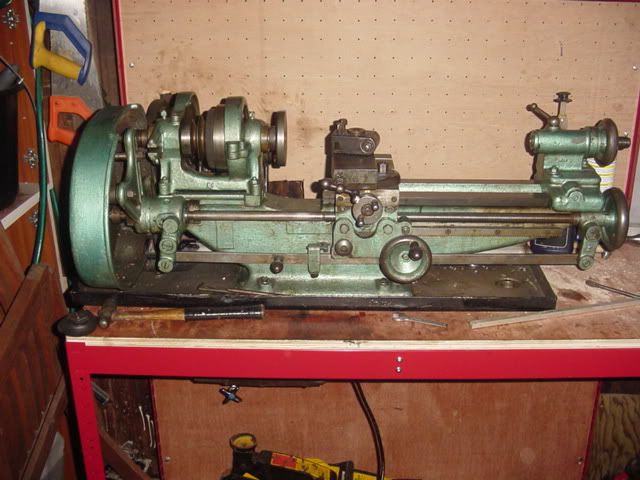

So it's in! It has the worlds largest single phase 1/2 horsepower motor and a proper Drummond counter shaft and motor mount - it's just arranged in a slightly non-standard way to save a bit of space.

It has a lead screw and loads of change wheels, it's missing one from the set but I have possibly found one. Lead screw nut is a bit worn but it'll still feed accurately enough.

It has 3 and 4 jaw chucks too.

The motor wiring is best before 1960 so I plan on changing it all tomorrow and the reverse switch is very tired, will be one of the first projects I think.

Oiling regime is every time - oil it! I'm using gearbox oil, GL4 as it's bronze friendly and I have some handy...

Excited...

It has a lead screw and loads of change wheels, it's missing one from the set but I have possibly found one. Lead screw nut is a bit worn but it'll still feed accurately enough.

It has 3 and 4 jaw chucks too.

The motor wiring is best before 1960 so I plan on changing it all tomorrow and the reverse switch is very tired, will be one of the first projects I think.

Oiling regime is every time - oil it! I'm using gearbox oil, GL4 as it's bronze friendly and I have some handy...

Excited...

Shox Dr

Chief Engineer to Carlos Fandango

- Messages

- 17,868

- Location

- East Yorkshire

Have a look at lathes.co.uk , a vast resource for info on lathes, milling machines etc

LOL

The only problem with this setup is the massive hole in the worktop, but it's 18mm thck ply and heavily braced so should be OK...

It's all wired in and running! Even turned a little bit of ali bar last night - need to learn to make proper tools though, I seem to have hundreds of 60 degree tooling adn no rounded tips. The drum switch internals are very tired but I now have some copper plate and silversteel to make replacement parts.

Sadly I have found that the motor has a load of cracks in the back cover, it's OK for now but won't last forever - maybe only another 20 years or so...

The only problem with this setup is the massive hole in the worktop, but it's 18mm thck ply and heavily braced so should be OK...

It's all wired in and running! Even turned a little bit of ali bar last night - need to learn to make proper tools though, I seem to have hundreds of 60 degree tooling adn no rounded tips. The drum switch internals are very tired but I now have some copper plate and silversteel to make replacement parts.

Sadly I have found that the motor has a load of cracks in the back cover, it's OK for now but won't last forever - maybe only another 20 years or so...