- Forums

- Tools, Compressors and Metal Coatings

- Tools, Materials and Techniques

- Machining

- Lathes and other Machining Equipment

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

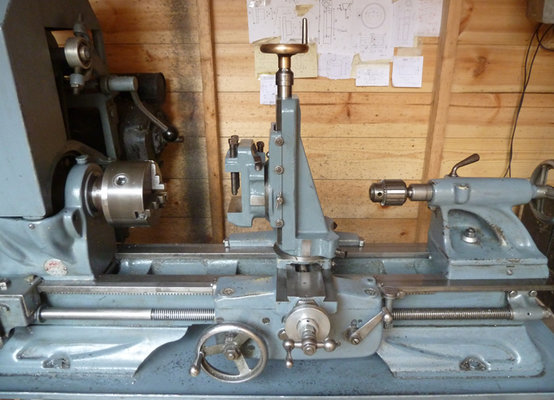

Identify this Cross Slide / Table

- Thread starter Brad93

- Start date

gaz1

Member

- Messages

- 20,156

- Location

- westyorkshire

Agroshield

Member

- Messages

- 6,043

...does the slide have any holes drilled in the other end...

Those are very good questions. If the nut fits the part, it does not need anything else in order for it to move under positive control. Compare and contrast a cross slide, where the nut is in the sliding part to the Myford vertical slide above, where the nut is in the fixed body (and thus does need holes in the end).

It might not be Centec as the slots are 90 degrees to the dovetail; mills generally have the slots parallel with the dovetail.

All the pictures of the table for the Boxford vertical slide table show a V-slot and a boss on the back of it, so that would seem to rule out that manufacturer.

Assuming the nut fits the slide, can you work out the diameter and pitch of the screw that fits it?

When measuring T-slots, it is the narrower dimension which is useful, not the base dimension.

Keep it, clean it up, cut off the dovetails from the bottom and use it as a set up plate or mini-pallet. Lots of ways to clamp fiddly things to it aligned with one of its edges and then clamp the whole thing to an angle plate at the angle you need. If the hole is in the centre of it, it can be used in a horizontal orientation - hold a bar in the mill spindle and poke it into the hole and it is automatically centred with the spindle. Rotate to desired angle using protractor against edge of mill table and clamp.