BrokenBiker

Member

- Messages

- 12,959

- Location

- Newport, South Wales

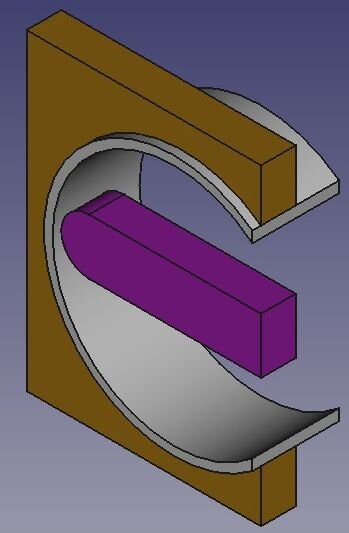

i need to hold a length of stianless tube in my abrasive shop saw, but the snag is, it needs to have 15mm cut off through the length, so leaves me with a 60mm and 75mm tall C profile and i need the open/cut face to be vertical to allow me to set the vice at 18 degrees and get the segments i need.

my first thought was to mark it out for the cuts, then tack a bit of steel barto the cut face to give me a flat surface for the vice, putting the tacks in the 'scrap' areas so as not to dilute the stainless i actually need, but im wondering if anyone has any other/easier ideas. it needs to be flipped in the vice between each cut, i need 10 segments so 20 cuts total.

i did think of cutting the segments first then trimming the 15mm off but then i wont get the right shape as i need the segments to come to a point.

extra points for anyone that can guess what im making.

my first thought was to mark it out for the cuts, then tack a bit of steel barto the cut face to give me a flat surface for the vice, putting the tacks in the 'scrap' areas so as not to dilute the stainless i actually need, but im wondering if anyone has any other/easier ideas. it needs to be flipped in the vice between each cut, i need 10 segments so 20 cuts total.

i did think of cutting the segments first then trimming the 15mm off but then i wont get the right shape as i need the segments to come to a point.

extra points for anyone that can guess what im making.