CRS51

Member

- Messages

- 268

- Location

- Cheshire, England

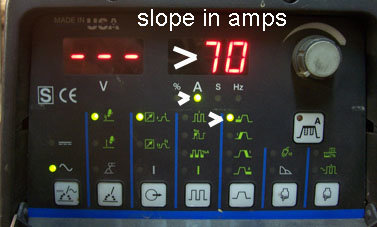

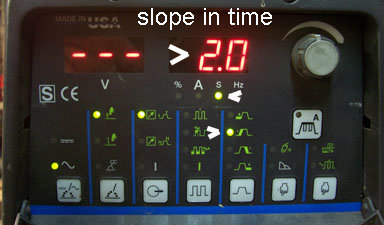

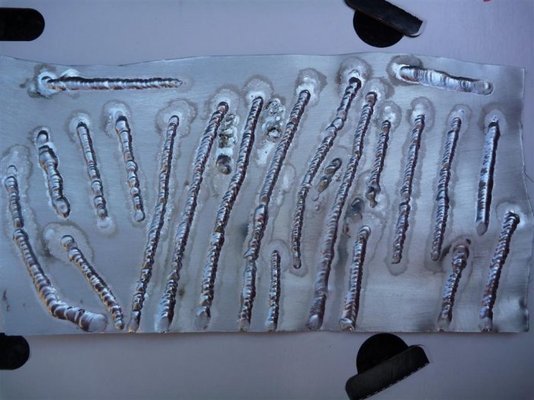

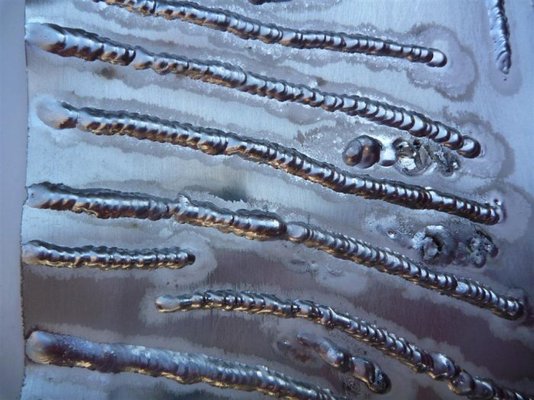

Hello all have been doing quite a bit of welding with my new Rtech welder but have come up against a problem. When using the hf start on very thin aluminium the first second or so seems too strong a current and melts the material or blows a hole in it.

Also can't manage to use the 1mm tungstons on aluminium as when using the hf it melts the tungston to oblivion and the tip ends up inside the ceramic.

Have been trying 1mm tungston on .75mm sheet using 1mm filler rods, gas is 8lpm, amps have been set to 46 max and have tried down to 10 (lowest setting) also using the foot pedal, have tried pulse on and off but to no avail. Manages to use the 1.6 tungstons ok, have tried both zirc and lanth tungstons.

Is 10 amps too much for a 1mm tungston or is it the machine is giving out too much current on start up for the hf start ?

Any advce welcome

Chris.

Also can't manage to use the 1mm tungstons on aluminium as when using the hf it melts the tungston to oblivion and the tip ends up inside the ceramic.

Have been trying 1mm tungston on .75mm sheet using 1mm filler rods, gas is 8lpm, amps have been set to 46 max and have tried down to 10 (lowest setting) also using the foot pedal, have tried pulse on and off but to no avail. Manages to use the 1.6 tungstons ok, have tried both zirc and lanth tungstons.

Is 10 amps too much for a 1mm tungston or is it the machine is giving out too much current on start up for the hf start ?

Any advce welcome

Chris.