northwest

Searching for the Holy Grail.........

- Messages

- 6,653

- Location

- Manchester UK

But I know why. No, it's not the shear pin or clutch pack, definitely the gearbox having an issue. I went online to see where to start and although there is one old boy made a series of quite informative video's some of his techniques are questionable at best, also, one of my pet hates, a carpentry hammer used in an engineering application:

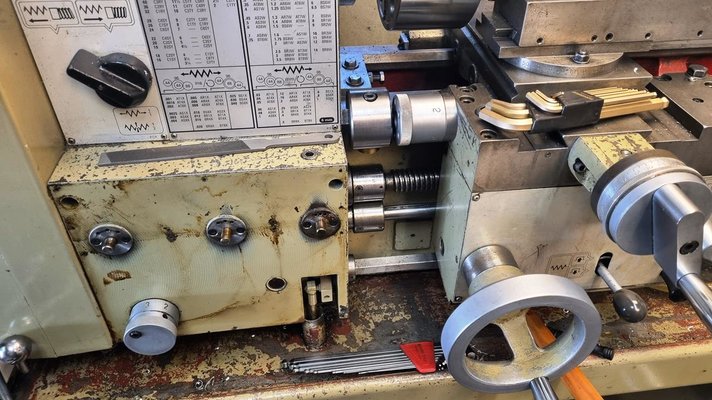

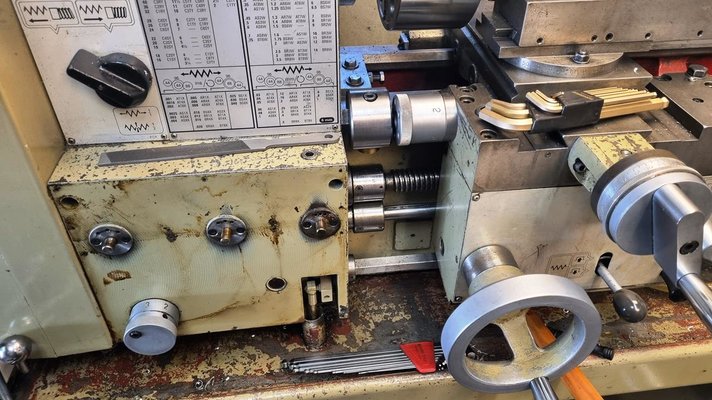

So, this is where I started, ally plates off then the selector knobs (lookout for the detent balls and springs):

Then there are a few important bits to do, the on/off control needs disconnecting then screw the extension off the rod so you can physically remove the gearbox, then take out the two bolts holding the leadscrew drive rod and on/off lever control at the tailstock end, wind the saddle towards the headstock, lift the bracket off the pins at the tailstock, engage the half nuts and wind the whole lot out of the drive ends, like this:

You did remember to remove the bracket from the on/off control right?

Then you need to look at getting the five bolts and one button head holding it in place, you will need a 6mm Allen key for this and something like a ring spanner or piece of tube for leverage.

You will also need to remove the 80tooth gear from the input shaft, you can see where the button head came from, it holds the guard in place:

Then drain the oil:

It was never not going to be messy! Gearbox off and exposing the dried on crud of soluble oil from years back:

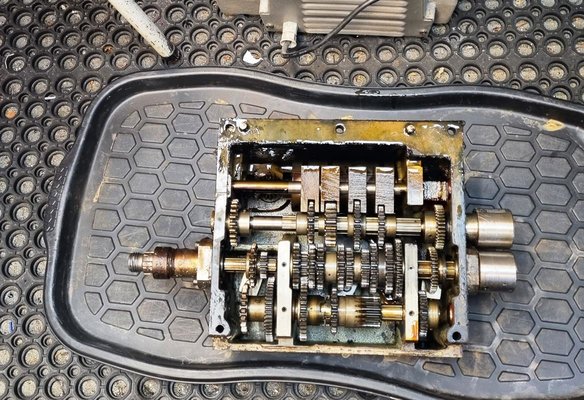

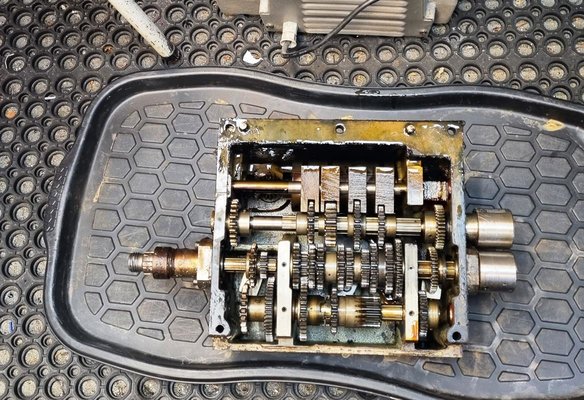

Now the gearbox on the floor and I can start to work out where the damage/fault is. I set it up exactly where it was when I broke it and worked back from there:

Bit of fiddling and twiddling and it was this roll pin here, at the tip of the screwdriver:

New paragraph:-)

So, this is where I started, ally plates off then the selector knobs (lookout for the detent balls and springs):

Then there are a few important bits to do, the on/off control needs disconnecting then screw the extension off the rod so you can physically remove the gearbox, then take out the two bolts holding the leadscrew drive rod and on/off lever control at the tailstock end, wind the saddle towards the headstock, lift the bracket off the pins at the tailstock, engage the half nuts and wind the whole lot out of the drive ends, like this:

You did remember to remove the bracket from the on/off control right?

Then you need to look at getting the five bolts and one button head holding it in place, you will need a 6mm Allen key for this and something like a ring spanner or piece of tube for leverage.

You will also need to remove the 80tooth gear from the input shaft, you can see where the button head came from, it holds the guard in place:

Then drain the oil:

It was never not going to be messy! Gearbox off and exposing the dried on crud of soluble oil from years back:

Now the gearbox on the floor and I can start to work out where the damage/fault is. I set it up exactly where it was when I broke it and worked back from there:

Bit of fiddling and twiddling and it was this roll pin here, at the tip of the screwdriver:

New paragraph:-)