TonyWilk

2-Pint Welder

- Messages

- 114

Hi,

Was trying to cut up some 6mm thick 80mm angle today (adjusting the size of a HUGE metal bench)...

Got bored with the grinder after the first cut and dragged out my cheapy plasma cutter.

Melted and set fire to the plasma tip/shroud after another 2 cuts , so back to the grinder with a cutting disc.

, so back to the grinder with a cutting disc.

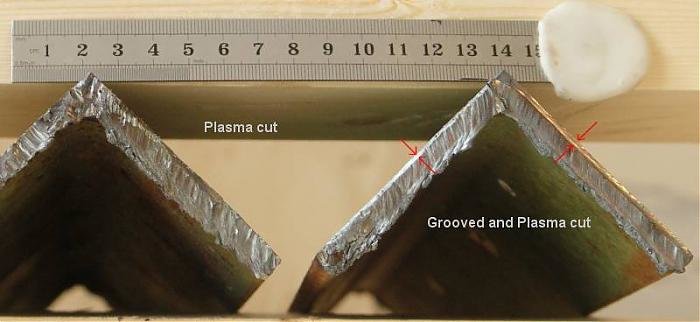

Then had an idea: I cut a 1-2mm deep groove with the grinder and tried the plasma (with new bits) again... worked really well

With the plasma tip being a contact type and asking it to work hard on 6mm steel, the tip gets spattered and ends up knackered pretty quick - with a groove to cut into (which is only 2-3mm wide) it seems to prolong the life of the tip enormously and cuts quicker.

I made a further seven cuts with the groovy method and the tip's still in fine fettle

Yours,

Tony Wilk

Was trying to cut up some 6mm thick 80mm angle today (adjusting the size of a HUGE metal bench)...

Got bored with the grinder after the first cut and dragged out my cheapy plasma cutter.

Melted and set fire to the plasma tip/shroud after another 2 cuts

, so back to the grinder with a cutting disc.

, so back to the grinder with a cutting disc.Then had an idea: I cut a 1-2mm deep groove with the grinder and tried the plasma (with new bits) again... worked really well

With the plasma tip being a contact type and asking it to work hard on 6mm steel, the tip gets spattered and ends up knackered pretty quick - with a groove to cut into (which is only 2-3mm wide) it seems to prolong the life of the tip enormously and cuts quicker.

I made a further seven cuts with the groovy method and the tip's still in fine fettle

Yours,

Tony Wilk