You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Gota laugh at this lad.

- Thread starter ukracer

- Start date

Shedendman

Member

- Messages

- 5,586

Is this a case of if its not broke dont fix it?

Well it was broke...but he was selling it for the stand...so he had a bit of fun..lolIs this a case of if its not broke dont fix it?

WorkshopChris

Member

- Messages

- 5,049

- Location

- South East Essex

That's 3 mins of my life wasted, what a clown the jaws had so much play you could see them move as the turned the stock and tightened them, what was he expecting to happen. That's the problem with youtube 1000's of videos all showing bad practice then 100's of people watch, repeat and upload till everyone thinks that's the way to sort a problem.

Hood

Member

- Messages

- 17,984

- Location

- Carnoustie, Scotland

Ok a few options here.

First is on a CNC it is common to use soft jaws and to bore them out to a particular size for a particular part, it may have a shape or steps or taper or whatever to it.

As you can see in this pic they are usually 2 part jaws so you have a space at the bottom where you can clamp a small disc or whatever.

When you have soft jaw tops on they will likely overhang further so you can usually even clamp a ring in.

Here is a soft top jaw that has been bored to suit some hauler plates.

And here is a bit I made up instead of just using a disc, it makes it easier to remove without having to remove a soft top jaw as CNC chucks usually only have about 5 mm travel per jaw.

Then you can also use the holes that clamp the jaws together when you have an adjustable ring like this one I made. You slide each pin round in the slot and then place them in the cap screw holes on the jaw.

That can be used for loading the chuck jaws both ways, so for doing both the faces for external part gripping or by loading the chuck the opposite way for internal part gripping.

That can also be done with a ring such as I use on the manual lathe, see below pic which would be for boring out the section arrowed, again usually on soft jaws but I actually used it on these jaws as they were not matched so had some runout.

.

Years ago I made a part for doing the chuck on my Colchester student, cant find the part but here is the drawing.

It gripped on the side angles of the jaws so that it left the face clear, maybe this will show how it fitted.

There are lots of other ways to load the jaws but the important thing is always load in the direction you will be using when clamping the part.

First is on a CNC it is common to use soft jaws and to bore them out to a particular size for a particular part, it may have a shape or steps or taper or whatever to it.

As you can see in this pic they are usually 2 part jaws so you have a space at the bottom where you can clamp a small disc or whatever.

When you have soft jaw tops on they will likely overhang further so you can usually even clamp a ring in.

Here is a soft top jaw that has been bored to suit some hauler plates.

And here is a bit I made up instead of just using a disc, it makes it easier to remove without having to remove a soft top jaw as CNC chucks usually only have about 5 mm travel per jaw.

Then you can also use the holes that clamp the jaws together when you have an adjustable ring like this one I made. You slide each pin round in the slot and then place them in the cap screw holes on the jaw.

That can be used for loading the chuck jaws both ways, so for doing both the faces for external part gripping or by loading the chuck the opposite way for internal part gripping.

That can also be done with a ring such as I use on the manual lathe, see below pic which would be for boring out the section arrowed, again usually on soft jaws but I actually used it on these jaws as they were not matched so had some runout.

.

Years ago I made a part for doing the chuck on my Colchester student, cant find the part but here is the drawing.

It gripped on the side angles of the jaws so that it left the face clear, maybe this will show how it fitted.

There are lots of other ways to load the jaws but the important thing is always load in the direction you will be using when clamping the part.

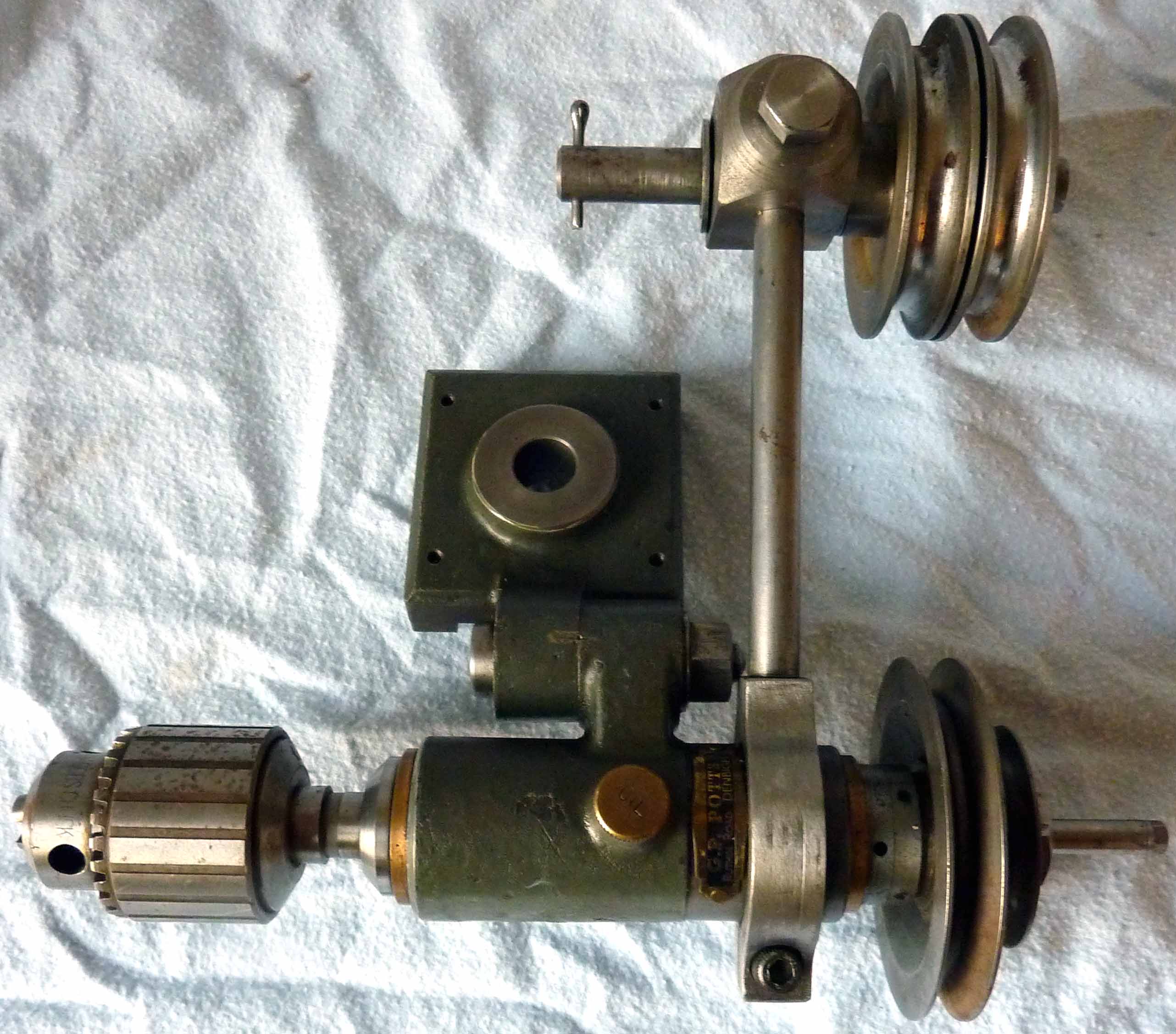

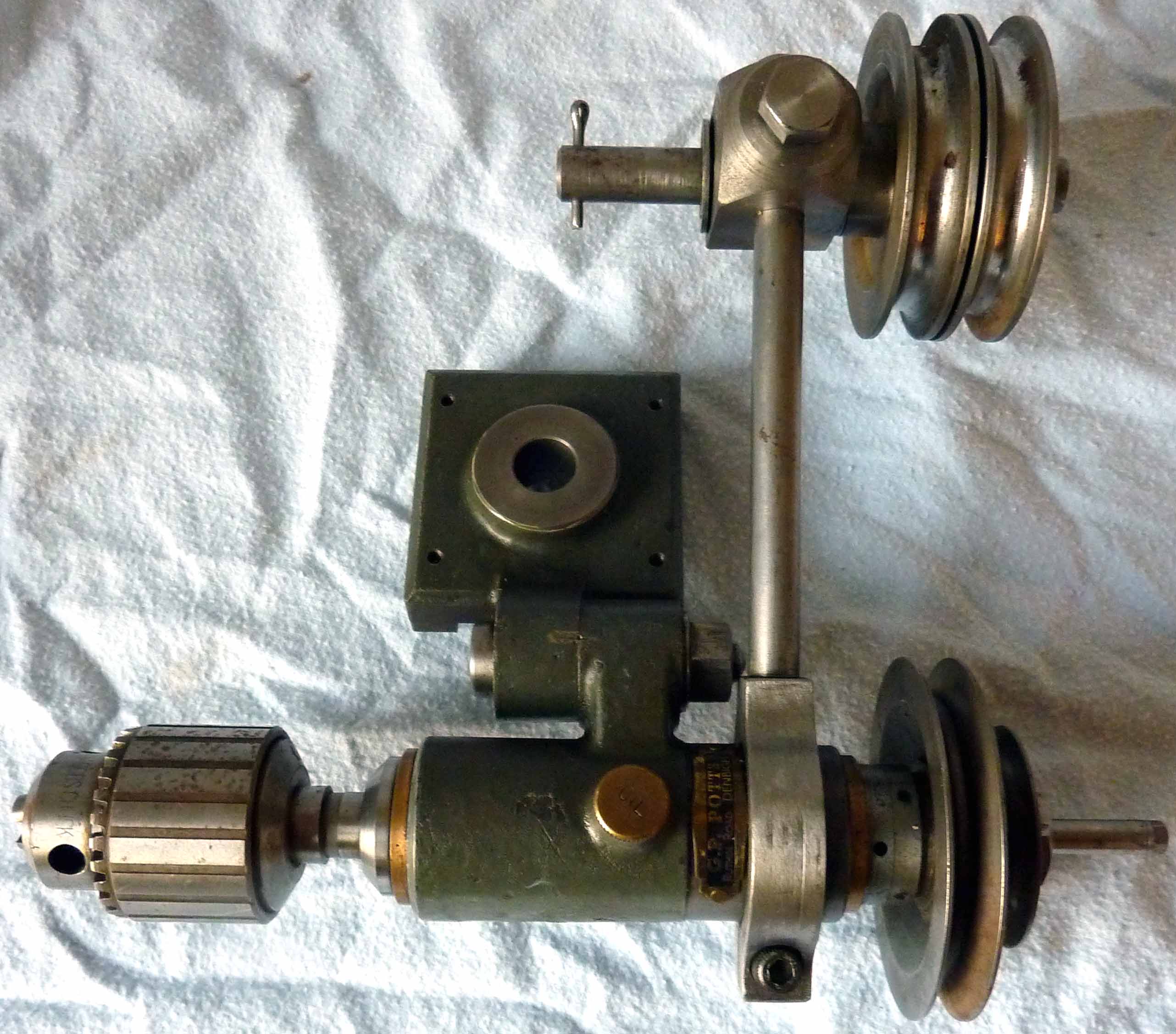

Im laughing, but Im looking at making a tiny milling spindle to regrind the jaws for my 3 jaw chuck. I saw a picture if the Potts mk2 milling attachment and its the direction Im heading in, with a 12v motor in place of the second set of pulleys and use ER collets

http://www.lathes.co.uk/potts/

hopefully my version will work better than the one in the video, (but only time will tell)

http://www.lathes.co.uk/potts/

hopefully my version will work better than the one in the video, (but only time will tell)

Seadog

Save the planet. It's the only one with rum!

- Messages

- 13,065

- Location

- NE London - UK

I've bought one of these for my toolpost grinder - http://www.ebay.co.uk/itm/220V-180W...714413&hash=item3d4212826b:g:XR4AAOSwiIxaSur6

just have the jaws loaded correctly and away you go

just have the jaws loaded correctly and away you go