- Messages

- 14,624

- Location

- UK

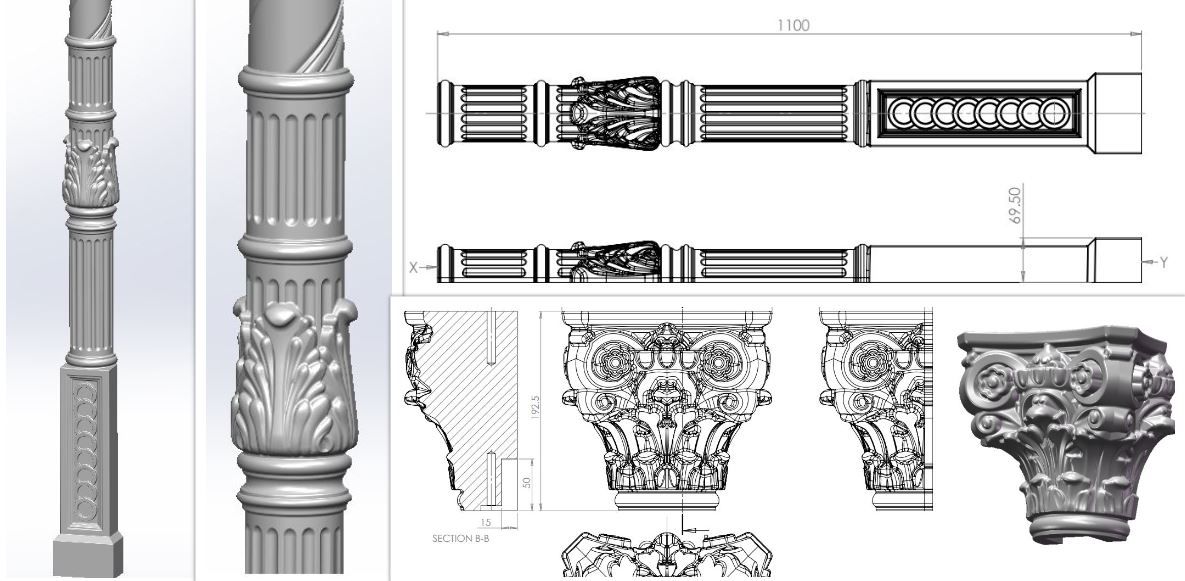

We're doing some work on a large Grade 1 listed building. Once the structural steel was erected, we were asked if we knew anyone who could form some replica cast iron columns. 40 to do.

Always up for a challenge, we arranged for a 3D scan of an existing column, some CAD trickery to obtain CNC toolpath data, used a 5 axis mill to form male moulds, cast female rubber moulds off these, then cast the columns in glass reinforced concrete.

The columns are split into 3 pieces, the base, and finial which are standard items, then the central fluted part is cut to suit the overall height of our structure behind.

People seem fairly impressed, which is always good.

Another 60 to do on Phase 2.

Always up for a challenge, we arranged for a 3D scan of an existing column, some CAD trickery to obtain CNC toolpath data, used a 5 axis mill to form male moulds, cast female rubber moulds off these, then cast the columns in glass reinforced concrete.

The columns are split into 3 pieces, the base, and finial which are standard items, then the central fluted part is cut to suit the overall height of our structure behind.

People seem fairly impressed, which is always good.

Another 60 to do on Phase 2.