RonMig

Member

- Messages

- 506

- Location

- UK M1 J16

I bought some Parkside 0.6 flux-core wire a long time ago, from Lidl I think - anyone else grab some to use as a dust-bunny-grabber?

I've not welded anything for several months, so decided to give it a try.

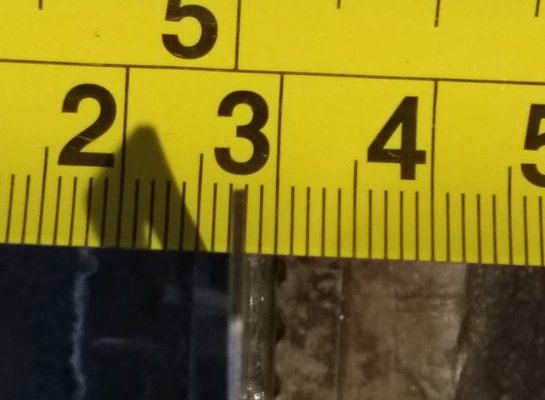

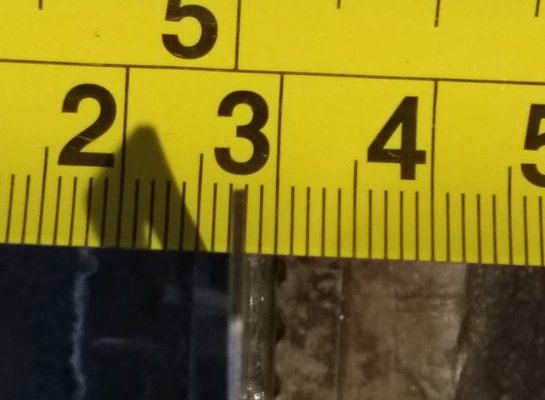

Got some smallish bits of sheet (donated from a computer, I think?) and measured it at 1mm thick.

It's a bit bendy so is probably chinesium very mild steel... hmm, not quite up to car body standards but will do for testing...

With this 0.6 fluxcore wire, I found it works nice on nbr 1 and with the lowest wirespeed, nice sizzle.

Still looks a bit messy, but that's probably my lack of skill

And penetration seems good...

I'm surprised how small the spot welds are...

Never mind the reading glasses, I need a magnifying glass !

Made it tricky to use the overlap technique which I was trying to do, another skill failure.

Continuous weld would just burn through, I think.

Anyone else tried the 0.6 fluxcore wire?

I've not welded anything for several months, so decided to give it a try.

Got some smallish bits of sheet (donated from a computer, I think?) and measured it at 1mm thick.

It's a bit bendy so is probably chinesium very mild steel... hmm, not quite up to car body standards but will do for testing...

With this 0.6 fluxcore wire, I found it works nice on nbr 1 and with the lowest wirespeed, nice sizzle.

Still looks a bit messy, but that's probably my lack of skill

And penetration seems good...

I'm surprised how small the spot welds are...

Never mind the reading glasses, I need a magnifying glass !

Made it tricky to use the overlap technique which I was trying to do, another skill failure.

Continuous weld would just burn through, I think.

Anyone else tried the 0.6 fluxcore wire?