paulmowers

Member

- Messages

- 192

- Location

- Norfolk, uk

Hi All

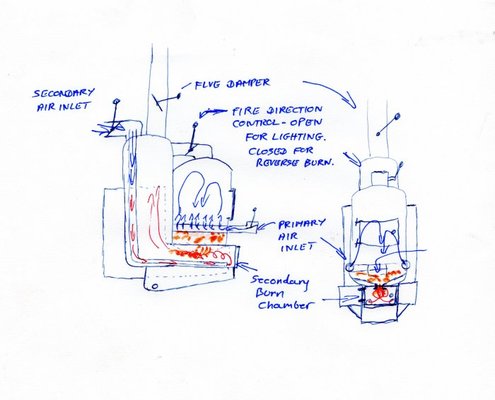

Anyone remember my prototype gasifying boiler from last year? Well it kind of got to the point of being installed, one test firing which was a bit disapointing as it failed to burn downwards, just smouldered and then went out.

Had a major refit in the house at the time with fitting a rojek wood boiler and accumulator tank, so with the choices of a warm house or warm workshop, went for the warm house option and the workshop under lpg heater for another year.

Till today when I decided the reason it failed to gasify was due to there not being a large enough gap in the base of the firebox for it to draw the flame down and then mix with the secondary air.

So today out with the plasma cutter and I doubled the width of the slot to just over 1/2" wide, it was the width of a cutting disc 6mm ish.

Second test burn, and it roars like a little jet engine, burning scrap ends of powdery wood and sawdust.

And the heat exchanger is getting very hot which should be good when I get the plumbing sorted and some water in it.

And the heat exchanger is getting very hot which should be good when I get the plumbing sorted and some water in it.

First pic is of the fire from the fire door, only problem with trying to take pics is once a door is open the air flow is disrupted and the gasifying (downward burn) process stops.

Which is why the second pic, of the secondary combustion chamber shows a rather pathetic little flame as opening the door stopped the burn.

Pic three is the beast from the front.

Paul..

Anyone remember my prototype gasifying boiler from last year? Well it kind of got to the point of being installed, one test firing which was a bit disapointing as it failed to burn downwards, just smouldered and then went out.

Had a major refit in the house at the time with fitting a rojek wood boiler and accumulator tank, so with the choices of a warm house or warm workshop, went for the warm house option and the workshop under lpg heater for another year.

Till today when I decided the reason it failed to gasify was due to there not being a large enough gap in the base of the firebox for it to draw the flame down and then mix with the secondary air.

So today out with the plasma cutter and I doubled the width of the slot to just over 1/2" wide, it was the width of a cutting disc 6mm ish.

Second test burn, and it roars like a little jet engine, burning scrap ends of powdery wood and sawdust.

And the heat exchanger is getting very hot which should be good when I get the plumbing sorted and some water in it.

And the heat exchanger is getting very hot which should be good when I get the plumbing sorted and some water in it.First pic is of the fire from the fire door, only problem with trying to take pics is once a door is open the air flow is disrupted and the gasifying (downward burn) process stops.

Which is why the second pic, of the secondary combustion chamber shows a rather pathetic little flame as opening the door stopped the burn.

Pic three is the beast from the front.

Paul..