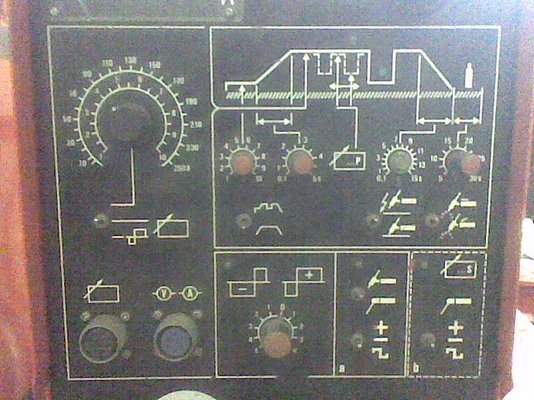

Hi all, I have been welding mma and o/a for almost 40 years now, around 15 years ago I took up mig welding and did'nt have too many probs getting up to it. Now I have bought a Fusion 200 PHF inverter mainly because I like dc for mma, but since I now have tig I would also like to learn it but there are too many confusing settings on this machine for me to understand. I have obtained a cylinder of BOC argon connected it all up, set things roughly to what I thought they should be, went ahead and attempted to weld and made a mess! Burn through, porosity etc. Can some one tell me how I shoud set this machine please? Say I am going to tig some mild steel, 1mm thick plate. Gas on, power on and inverter selector set at tig, HF start on. What size of ceramic nozzle and tungsten? What size of filler rod? What should 'pre gas' time be set at? What should the 'start current' be set at? What should the welding current be set at? What should the 'up slope' time be set at? Should I switch on 'pulse'? If so, what should the pulse current be set at? What should the 'pulse base time' be set at? What should the 'high pulse time' be set at? What should the 'down slope time be set at? What should the 'crater amps' be? What should the 'crater time be? What should the 'post gas time' be set to? Sorry to ask so many questions but I dont understand the tig settings, the manual that came with the set says its simplistic to set up, well yeah, probably for someone who is experienced with tig but for me, its the first time I have seen a tig machine and I dont have anyone near to ask. Thank you very much in advance for any help with any of the above questions. Bsmith (",).

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Fusion inverter 200 PHF

- Thread starter Bsmith

- Start date

I'm also dreading the settings once my TIG arrives....I found some Miller TIG Welding calculators on fleabay but they worked out quite expensive, but only cost me $4 from the official website inc. postage from the US to UK.

Or you can use this for now if it helps CLICKY (Mods please remove if this is not allowed)

Or you can use this for now if it helps CLICKY (Mods please remove if this is not allowed)

malcolm

& Clementine the Cat

- Messages

- 9,824

- Location

- Bedford UK

It's not a lot of help, but I've found it much easier to learn TIG using a larger tungsten. Also my first attempts at 1mm were terrible and didn't help me learn. Go with 2mm sheet and a 2.5mm tungsten for learning thin metal.

Some of the settings on your Inverter Fusion are quite fancy. On mine I had start current, pulse, and crater fill off. They can come in later for fine tuning. Again for learning if upslope and downslope times are set to a minimum you'll spend all the time on constant settings for the actual weld.

Some of the settings on your Inverter Fusion are quite fancy. On mine I had start current, pulse, and crater fill off. They can come in later for fine tuning. Again for learning if upslope and downslope times are set to a minimum you'll spend all the time on constant settings for the actual weld.

shenion

Tool Pack Rat

- Messages

- 7,582

- Location

- Stone Mountain, GA USA

Use the Miller Calculator to get the tungsten size, shroud size and current settings.

I'd suggest disabling all the pulse functions. Up slope minimum. Then it will be similar to using an O/A setup. Once you get comfortable with that, you can use the pulse settings to automate things a bit.

I use a 10 second post flow for 1.6mm.

I'd suggest disabling all the pulse functions. Up slope minimum. Then it will be similar to using an O/A setup. Once you get comfortable with that, you can use the pulse settings to automate things a bit.

I use a 10 second post flow for 1.6mm.

hi, cant you bypass the slope in/out and pulse settings while you get started, try welding at about 75 to 80 amps, you got pure argon, thats right, earth + torch -. sharpen your tungsten, stick out from the torch about 6mm. try to use bright mild steel for practise and wipe any oil off.

shenion

Tool Pack Rat

- Messages

- 7,582

- Location

- Stone Mountain, GA USA

Yes, try thicker metal. my first attempt was 1/8" mild steel. Thought, "this is easy". Then tried thin stuff and aluminum and was much harder.

Mine does not have all those fancy features. Just on/off and a post flow timer (with a tungsten size on the dial.) I use a footpedal, I find it easier except only works on bench where you can sit down. Hard to balance with both hands full, one foot on pedal

If you have done O/A then you should pick up TIG. It is similar with one big exception; move the torch farther away and it gets hotter. Keep the tungsten as close as possible to keep the weld pool small.

Mine does not have all those fancy features. Just on/off and a post flow timer (with a tungsten size on the dial.) I use a footpedal, I find it easier except only works on bench where you can sit down. Hard to balance with both hands full, one foot on pedal

If you have done O/A then you should pick up TIG. It is similar with one big exception; move the torch farther away and it gets hotter. Keep the tungsten as close as possible to keep the weld pool small.

well you have a very nice machine there , i have a 200 HF , So basically the same machine without the pulse feature .

as has been said to start with dont use the pulse ,

thickish material etc

when using the tig all my work is either 1mm or 16 g stainless tube ,

if you fancy swoping machines let me know

cheers mike

as has been said to start with dont use the pulse ,

thickish material etc

when using the tig all my work is either 1mm or 16 g stainless tube ,

if you fancy swoping machines let me know

cheers mike

The majority of the parameters are more about 'fine tuning' (say repeatability in a production environment for example) than a necessity/important. For most people, most of the time they can be set once and (almost) forgotten about

Preflow: When welding exotics (or restricted access with loads of tungsten stick out) more preflow is useful to purge the area but for the most part all that's needed is argon to be present when the arc is struck. Set it to 0.5sec and forget it.

Starting current and slope up can be used to provide a soft start (avoid blowing hole on thin material) or a hot start (aluminium mainly). Personal preference plays a role but i would be looking at around 0.5 - 1sec slope up. If start current is set as a percentage then i'd start with around 75%, if it's set as an amperage then nothing wrong with just setting it really low for now to avoid having to keep adjusting it

Slope down and crater current are more useful as abrutly shutting the arc off leaves a crater. A couple of secs downslope will let the arc taper off smoothly, 50% crater current as a starting point.

Leave pulse switched off for now. Can take quite a bit of setting up, need to be consistent without it in order to set it up properly.

Main welding current... arc length, travel speed, joint type and even the size of the part can make a difference. 1mm steel will be around 30-45A, filler wire would really need to be 1.2mm or thinner (i would use 0.8 or 1mm personally).

Post flow is primarily to protect the tungsten while it cools, if it discolours (oxidises) then you need more. More amps = more postflow, 1sec/10A is a rough guide that (like the miller amp calculater) is closest around the middle amperages accuracy wise

Tungsten size is covered in the links already posted as are ceramic sizes although ceramics aren't really critical unless you try to use a tiny one at high amps. I use a #7 for most things occasionally smaller for access reasons, ocassionally much bigger for a better gas shield.

As the others have said thicker material will be easier to learn on

Preflow: When welding exotics (or restricted access with loads of tungsten stick out) more preflow is useful to purge the area but for the most part all that's needed is argon to be present when the arc is struck. Set it to 0.5sec and forget it.

Starting current and slope up can be used to provide a soft start (avoid blowing hole on thin material) or a hot start (aluminium mainly). Personal preference plays a role but i would be looking at around 0.5 - 1sec slope up. If start current is set as a percentage then i'd start with around 75%, if it's set as an amperage then nothing wrong with just setting it really low for now to avoid having to keep adjusting it

Slope down and crater current are more useful as abrutly shutting the arc off leaves a crater. A couple of secs downslope will let the arc taper off smoothly, 50% crater current as a starting point.

Leave pulse switched off for now. Can take quite a bit of setting up, need to be consistent without it in order to set it up properly.

Main welding current... arc length, travel speed, joint type and even the size of the part can make a difference. 1mm steel will be around 30-45A, filler wire would really need to be 1.2mm or thinner (i would use 0.8 or 1mm personally).

Post flow is primarily to protect the tungsten while it cools, if it discolours (oxidises) then you need more. More amps = more postflow, 1sec/10A is a rough guide that (like the miller amp calculater) is closest around the middle amperages accuracy wise

Tungsten size is covered in the links already posted as are ceramic sizes although ceramics aren't really critical unless you try to use a tiny one at high amps. I use a #7 for most things occasionally smaller for access reasons, ocassionally much bigger for a better gas shield.

As the others have said thicker material will be easier to learn on

some handy tips there hotrodder, looks like i could have been welding with oxidised tungsten for most of my working life, i thought you just had to resharpen all the time. i mainly TIG stainless 304 1.5mm at about 75-85 amps, but i think i might be to hot, it has to do with the travel speed as well i suppose. i learned to TIG on a big job i had to do once, 1/2" 1.2 tube welded into box with a 1/2 holes drilled in, not a great description their but i did over 2000, after that i could TIG.

Some VG info there guys. Thank you very much. I'll certainly turn off the pulse meantime and the fine tunings and have another go. Later have a little play with the pre flow and post flow and maybe the end crater. I thought I would buy the PHF Mickey D as its only around £30 dearer than the HF from Mig Tig Arc, they have a web site if you google it. Dunno where you had yours from, maybe the same place. Sorry dont intend to swap at present, I hope to get the spot welding fittings too. What do I do with the 6 inch pieces of filler rod ends that are left? With o/a I weld them onto the next rod, doubt if I could do that with tig. Many thanks again, you have all been a great help. Bsmith (",).

Tungsten tips do degrade with use and certainly need freshening up every now and again. Mild oxidation and they'll turn a greenish colour followed by blues purples to grey and mankey.

6" inch long stubs is a bit of a waste. Can be welded together easily enough but i wouldn't bother, just put 'em to one side and use when tacking things up when they get too short to weld with comfortably

You mentioned porosity in the OP, if you're using O/A filler with TIG that could be the cause. Mild steel TIG filler is different to O/A, contains deoxidisers that aren't necessary with oxy fuel.

6" inch long stubs is a bit of a waste. Can be welded together easily enough but i wouldn't bother, just put 'em to one side and use when tacking things up when they get too short to weld with comfortably

You mentioned porosity in the OP, if you're using O/A filler with TIG that could be the cause. Mild steel TIG filler is different to O/A, contains deoxidisers that aren't necessary with oxy fuel.

Tungsten tips do degrade with use and certainly need freshening up every now and again. Mild oxidation and they'll turn a greenish colour followed by blues purples to grey and mankey.

6" inch long stubs is a bit of a waste. Can be welded together easily enough but i wouldn't bother, just put 'em to one side and use when tacking things up when they get too short to weld with comfortably

You mentioned porosity in the OP, if you're using O/A filler with TIG that could be the cause. Mild steel TIG filler is different to O/A, contains deoxidisers that aren't necessary with oxy fuel.

Right, Thanks Hotrodder. I was indeed using O/A filler rods and as for playing with stainless I used some 0.8mm s/s mig wire.