- Forums

- Tools, Compressors and Metal Coatings

- Tools, Materials and Techniques

- Machining

- Machining Techniques and Materials

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Fusion 360 Co-Ordinate Output

- Thread starter Brad93

- Start date

Madis Moppel

Member

- Messages

- 53

- Location

- Estonia

In SolidWorks there's a Hole Table feature for drawings that automatically creates table for holes with x and y coordinates. Probably there's a similar feature in Fusion.I don't know (and don't like) Fusion, but I would expect one of the quickest ways to do it would be to create a drawing of the part and just dimension all the holes from some fixed point.

Agroshield

Member

- Messages

- 5,910

Put a point entity at each hole centre. Save just the points as an ASCII dxf. Open the dxf in Notepad and read off the coordinates from the Entities section of the dxf.

Saying that, it might not help you much as the points are listed in the order they are created. So unless you are diligent when creating them, you might have the first at 12 o'clock, the second at 6 o'clock, the third at 1130 etc (i.e. not in any logical order for minimising handle cranking when drilling).

If you had a map, I wonder how it would best be arranged so it makes for efficient machining. What does SW do in that respect? Start bottom left and go right then up? Start top left and go down, across and then back up?

Saying that, it might not help you much as the points are listed in the order they are created. So unless you are diligent when creating them, you might have the first at 12 o'clock, the second at 6 o'clock, the third at 1130 etc (i.e. not in any logical order for minimising handle cranking when drilling).

If you had a map, I wonder how it would best be arranged so it makes for efficient machining. What does SW do in that respect? Start bottom left and go right then up? Start top left and go down, across and then back up?

Hood

I am obsessed.

- Messages

- 17,597

- Location

- Carnoustie, Scotland

If the holes need to be sized quite accurately then I usually cut them slightly undersize with the plasma and then drill to finish. The accuracy of the positioning should be good with the plasma.Efficient isn't the main goal, i just want to do it more accurately than the plasma (which will cut the external profile.

Brad93

Member

- Messages

- 18,957

- Location

- Essex, United Kingdom

My plasma can dot holes but it's hit or miss whether it makes a neat dimple or a bit of a line where the arc switches on for too longIf the holes need to be sized quite accurately then I usually cut them slightly undersize with the plasma and then drill to finish. The accuracy of the positioning should be good with the plasma.

Brad93

Member

- Messages

- 18,957

- Location

- Essex, United Kingdom

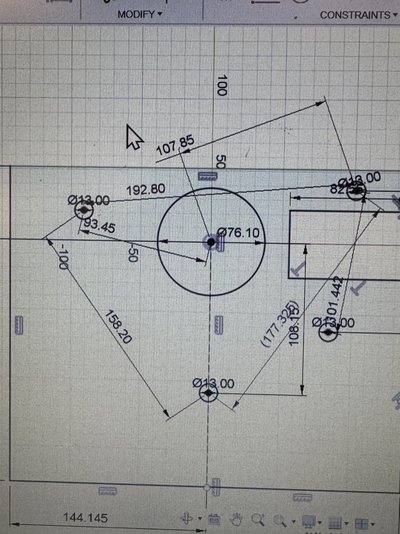

yes the third reply echos a post i found on the fusion forumThese replies any good?View attachment 461417

Hood

I am obsessed.

- Messages

- 17,597

- Location

- Carnoustie, Scotland

I cut the holes, just undersize, so for the 12mm in your example I would cut them 10mm then positional accuracy is good and the drill cleans them up nicely. The bigger hole in your drawing would likely be pretty good cut on the plasma.My plasma can dot holes but it's hit or miss whether it makes a neat dimple or a bit of a line where the arc switches on for too long

Brad93

Member

- Messages

- 18,957

- Location

- Essex, United Kingdom

You overestimate my plasma!I cut the holes, just undersize, so for the 12mm in your example I would cut them 10mm then positional accuracy is good and the drill cleans them up nicely. The bigger hole in your drawing would likely be pretty good cut on the plasma.

it still gets a ton of taper.

This a mounting for a clutch assembly on a Holbrook lathe so needs to be pretty accurate.

I figure 4 holes won't take too long with the DRO

Brad93

Member

- Messages

- 18,957

- Location

- Essex, United Kingdom

Yep, all i've got to do is reference the 3" centre hole as the origin/datum point.

Glad it made sense to you...lol. it's all gibberish to me currently.Yep, all i've got to do is reference the 3" centre hole as the origin/datum point.

Ali

Member

- Messages

- 1,864

- Location

- Cheshire

This is one of those things which often seem to crop up in CAD where you could draw it again in less time (and with less to go wrong) than the time taken to find out the clever way and attempt to execute it several times before getting frustrated and giving up. (Not intended as a smart*rse answer.)

Agroshield

Member

- Messages

- 5,910

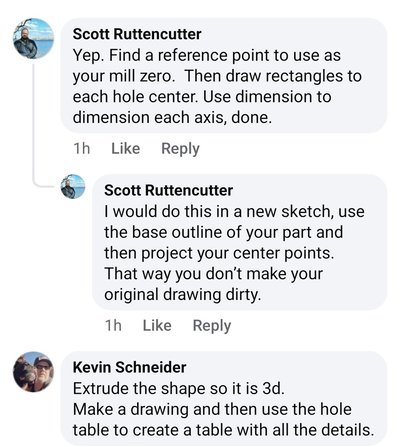

He just posted this...not sure if it's any use.

Yes, very much so, thanks. The keywords are 'hole table':