I bought a Fronius Transsteel 2200 back in late 2018 and it was working fine for a time, then in early 2021 it started to behave a bit weird.

when in synergic mode it would sometimes sputter and rapidly shoot out 100 mm or so of halfmolten wire when I was starting a weld.

this problem only happened sometimes and only in the synergic mode.

I could still use the welder in the manual mode or sett the settings in synergic and switch over to manual and weld.

I however sent the welder back to where I bought it from so that they could have a look at it.

that was in august 2022 and by now the warranty had expired.

They thought that they could fix it by uppdating the software but according to them “the hole machine crashed” when they tried installing the uppdated software.

this seamed strange to me but i have a very limited understanding of the workings of these inverters.

After a lot of back and forth and the repair centre contacting fronius headquarters it was decided that the circuit board needed to be replaced.

after even more back and forth the general agent for fronius in sweden decided to pay all of the costs of the new circuit board and associated work.

this all sounded good.

the new circuit board arrived and was installed and the machine was sent back to me.

I have now tried it and is a bit uncertain if it still has something wrong.

one thing i noticed is that when I select 0.8mm steel wire and 75-25 gas in synergic mode I can only adjust the material thickness up to 3.7mm and it reads 23.8V

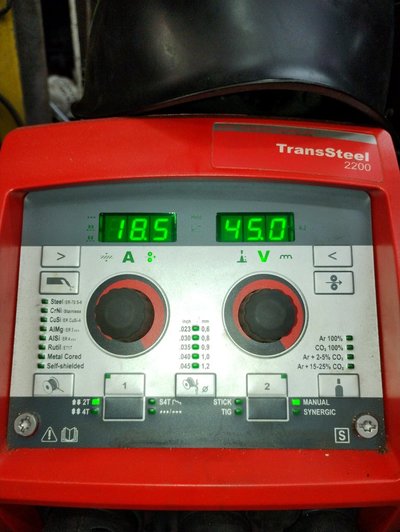

and in manual mode I can turn the Volts up to 45… I have not tried welding with this setting though.

I am wondering if there is anyone else with a transsteel 2200 that can tell me what the maximum thickness can be set in synergic mode with 0.8mm steel wire and 75-25 gas settings is?

I am a bit unsure but i think it was something like 5mm?

also can you really turn the volt dial up to 45 in manual mode???

thank you!

when in synergic mode it would sometimes sputter and rapidly shoot out 100 mm or so of halfmolten wire when I was starting a weld.

this problem only happened sometimes and only in the synergic mode.

I could still use the welder in the manual mode or sett the settings in synergic and switch over to manual and weld.

I however sent the welder back to where I bought it from so that they could have a look at it.

that was in august 2022 and by now the warranty had expired.

They thought that they could fix it by uppdating the software but according to them “the hole machine crashed” when they tried installing the uppdated software.

this seamed strange to me but i have a very limited understanding of the workings of these inverters.

After a lot of back and forth and the repair centre contacting fronius headquarters it was decided that the circuit board needed to be replaced.

after even more back and forth the general agent for fronius in sweden decided to pay all of the costs of the new circuit board and associated work.

this all sounded good.

the new circuit board arrived and was installed and the machine was sent back to me.

I have now tried it and is a bit uncertain if it still has something wrong.

one thing i noticed is that when I select 0.8mm steel wire and 75-25 gas in synergic mode I can only adjust the material thickness up to 3.7mm and it reads 23.8V

and in manual mode I can turn the Volts up to 45… I have not tried welding with this setting though.

I am wondering if there is anyone else with a transsteel 2200 that can tell me what the maximum thickness can be set in synergic mode with 0.8mm steel wire and 75-25 gas settings is?

I am a bit unsure but i think it was something like 5mm?

also can you really turn the volt dial up to 45 in manual mode???

thank you!