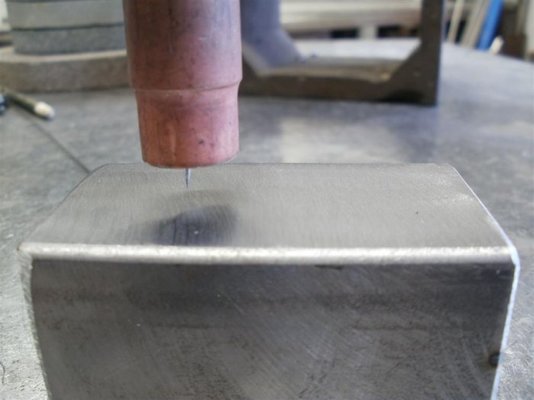

Hi Guys had a first attempt at tig using a dc inverter tig set, and it's not going well, although I'm ashamed to post these you've got to start somewhere and the only way to learn is to seek some advise, I wasn't going to try before I got some proper gear together, steel, tungstens, filler rods etc but being without a car until tomorrow I thought I would have a go and have had to make use with what was at hand. Steel is some old 2mm RHS, tungsten is a grey tipped 1.6 and the filler rod was 2.6mm copper coated for steel I believe but can't be certain, gas pure argon set to about 10lpm.

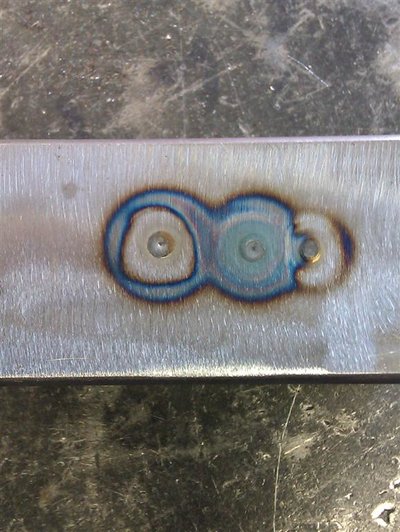

I can get the puddle to form ok, but it doesn't appear to want to move or flow forward as easily as the one in the tutorial video and the resultant bead when I get one has a coating of slag, It's rough looking and not clean and shiny. The steel was cleaned with a flap disc and was really shiny before I started, definitely getting gas out of the torch and pretty sure the torch angles where as per the tutorial.

Obviously I am not doing this correctly so where should I start to improve matters I am thinking that matching the tungsten and filler sizes would help and getting some new clean steel or possibly cleaning the steel with acetone before welding? I really want to crack this and appreciate that it's not a easy process or something you can learn in 5 minutes. I am going to see if there are any night school courses available but would appreciate any help or advice in the meantime.

I appreciate the amperage was way too high on some of these but I was adjusting amps and speed to find a starting point,

P.S go easy please, I have had a bad enough weekend with the car breaking down as it is

Thanks Norm

I can get the puddle to form ok, but it doesn't appear to want to move or flow forward as easily as the one in the tutorial video and the resultant bead when I get one has a coating of slag, It's rough looking and not clean and shiny. The steel was cleaned with a flap disc and was really shiny before I started, definitely getting gas out of the torch and pretty sure the torch angles where as per the tutorial.

Obviously I am not doing this correctly so where should I start to improve matters I am thinking that matching the tungsten and filler sizes would help and getting some new clean steel or possibly cleaning the steel with acetone before welding? I really want to crack this and appreciate that it's not a easy process or something you can learn in 5 minutes. I am going to see if there are any night school courses available but would appreciate any help or advice in the meantime.

I appreciate the amperage was way too high on some of these but I was adjusting amps and speed to find a starting point,

P.S go easy please, I have had a bad enough weekend with the car breaking down as it is

Thanks Norm