You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

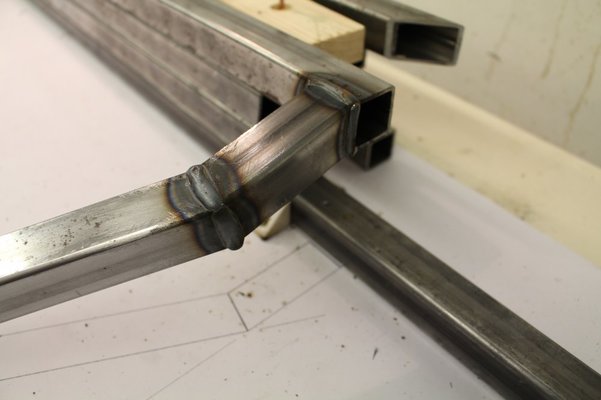

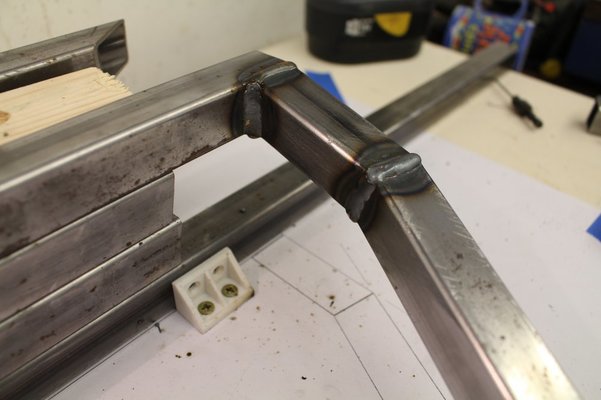

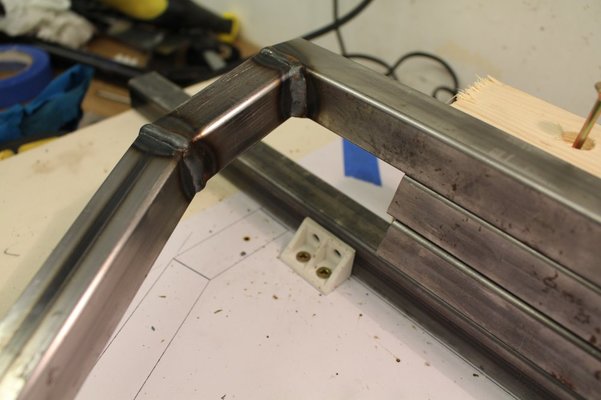

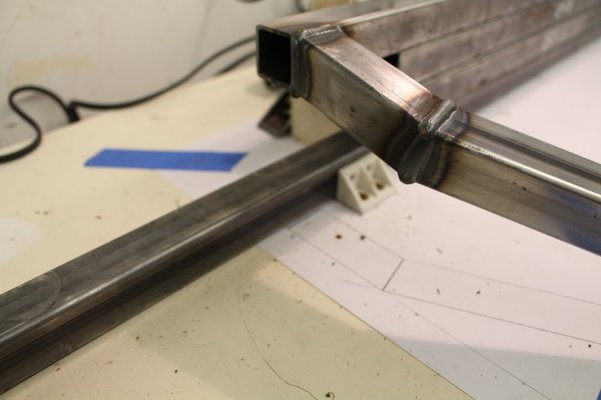

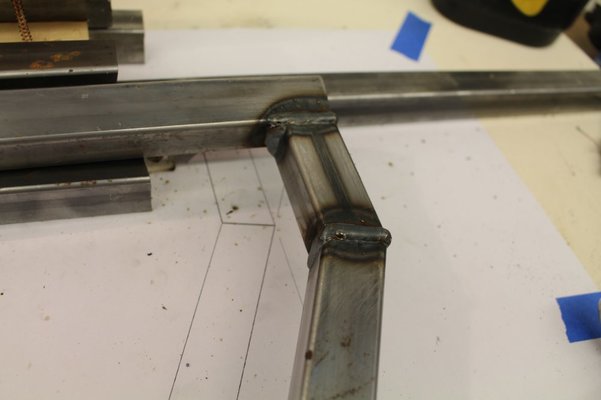

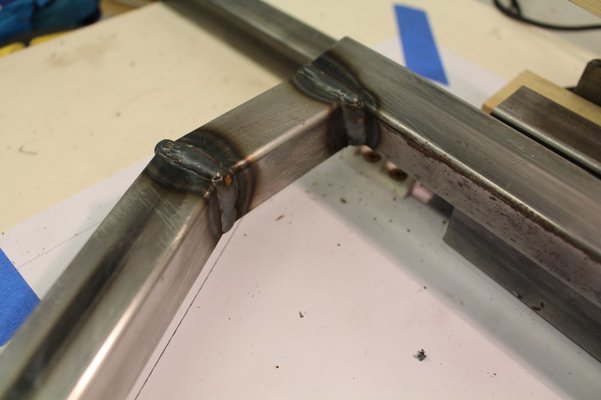

Feedback on some Mig runs

- Thread starter Barlidge

- Start date

It doesnt look to me that there all that bad the heat marks look like you are getting decent enough penetration some of the beadz do appear to be sitting up s bit high you could try turning your amps up a bit higher and moving a bit quicker to combat that but all in all not bad how long you been welding for?

Barlidge

Member

- Messages

- 1,054

- Location

- Langford, Bedfordshire, UK

I did stick and gas back in the day at college as part of an apprenticeship, and a little mig on the job, but that was almost 30 years ago lol. Career changed track onto an IT path and didn't touch another welder till about 18 months ago, got a tig and a mig and really just trying to practice whenever I get the chance, which is not as often as I'd like. I did a few test pieces prior to the piece in the picture to dial in the settings, all seemed ok but they were only really small offcuts so maybe they didn't dissipate the heat as much?

I think I'l chop some more offcuts and try a higher setting, although avoiding distortion is quite important, I have some spare box so making a new one is easy enough.

Thanks

I think I'l chop some more offcuts and try a higher setting, although avoiding distortion is quite important, I have some spare box so making a new one is easy enough.

Thanks

Burf86

Member

- Messages

- 218

- Location

- Frome, Somerset

Hey Barlidge, those weld dont look to bad. More practice will be the best thing for you really, some tips though.

When you arc up, hang around for a sec before moving on. This allows the pool to build up a bit and get some heat in. Some of your welds look the the beggining is thinner than the end and thats because you are starting to move too quickly. When moving on try to keep a consistant speed so the weld pool stay the same width while your moving. As the heat builds up you may have to speed up to keep the width. That stuff looks pretty thin but sometimes a V helps. Also, a tiny bit less wire speed on those welds would help with the buildup on some of them.

Keep practising, lots and lots of hood time is all you need

When you arc up, hang around for a sec before moving on. This allows the pool to build up a bit and get some heat in. Some of your welds look the the beggining is thinner than the end and thats because you are starting to move too quickly. When moving on try to keep a consistant speed so the weld pool stay the same width while your moving. As the heat builds up you may have to speed up to keep the width. That stuff looks pretty thin but sometimes a V helps. Also, a tiny bit less wire speed on those welds would help with the buildup on some of them.

Keep practising, lots and lots of hood time is all you need

Barlidge

Member

- Messages

- 1,054

- Location

- Langford, Bedfordshire, UK

Thanks Burf, that makes sense, its 2mm wall, If I understand you correctly your saying drop the wire speed a little and pay a little more attention to the first 5-10mm of the run then adjust the speed as the heat build up increases.

BrokenBiker

Member

- Messages

- 12,739

- Location

- Newport, South Wales

Perhaps I'm completely wrong, but did you leave a small gap between the pieces being welded? Without space for the weld puddle to 'sink in' between the pieces it has no option but to stay on top.

not always, if you have a high enough powered machine it will sink in, but for a hobby machine it is recommended as they usually don't have the powere required for a full penetration weld over a certain thickness. we have a 400 amp mig in work that will blow holes in 15mm steel so we never leave a gap for anything unless its on the drawing

Jan

Member

- Messages

- 881

- Location

- Rotherham, South Yorks

not always, if you have a high enough powered machine it will sink in, but for a hobby machine it is recommended as they usually don't have the powere required for a full penetration weld over a certain thickness. we have a 400 amp mig in work that will blow holes in 15mm steel so we never leave a gap for anything unless its on the drawing

Since the OP is a tyro like myself I assumed that his welder might not be of the best power/quality. For my sins I have an SIP 130, but at least it's been 'breathed on' to give a much better 'out of the box' experience.

Jan

Member

- Messages

- 881

- Location

- Rotherham, South Yorks

tyro? what that then?

Beginner/trainee/learner.

BrokenBiker

Member

- Messages

- 12,739

- Location

- Newport, South Wales

with that welder you wont need a gap on that thickness. as said above really just a bit more travel speed should flatten the welds out, but if your going to grind them back afterwards I wouldn't worry too much as long as they are strong

Barlidge

Member

- Messages

- 1,054

- Location

- Langford, Bedfordshire, UK

Beginner/trainee/learner.

Ah, NOOB

with that welder you wont need a gap on that thickness. as said above really just a bit more travel speed should flatten the welds out, but if your going to grind them back afterwards I wouldn't worry too much as long as they are strong

Picked it up for £300 2nd hand, although there's always a certain risk anything snd hand I figured it was better to get a good used one than a cheap new one, at least when fault finding I can really only look at user error

I Wasn't planning on grinding back unless its at a joint with another tube coming in, yes I'd like them to look as nice as possible and also thought they looked a bit high, my main concern was if they were too cold and lacked penetration.

BrokenBiker

Member

- Messages

- 12,739

- Location

- Newport, South Wales

easiest way to check is to mock up a joint with clean material the same as what you are using, weld it, then cut it open with a grinder and you can etch it with citric acid i think. Polish it up with a fine flap disc and swab the acid on

nick205

New Member

- Messages

- 26

- Location

- Winchester (UK)

Thanks, its Haynes flavoured, although its +100mm width and with a couple of other rail alterations. You building as well?

Working on a 205 GTI currently, but built an MK Indy a few years back after studing the Ron Champion Locost book so recognised the chassis form.

Are you a member of the Haynes Roadster and Locostbuilders forums?

If not, get signed up as there's a vast amount of experience and knowledge on both forums.