Hoping some of you metal work geniuses might be able to offer a bit of advice.

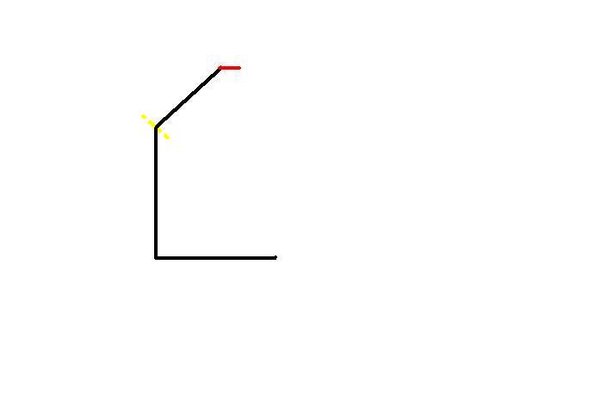

I've got a section of my 205 convertible that has rotted through fairly spectacularly and needs replacing. The section clamps the back part of the hood to the car. The part is still available from Peugeot but at a ridiculous price. I was therefore hoping to either get one fabbed or repaired myself.

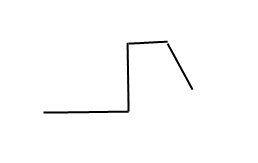

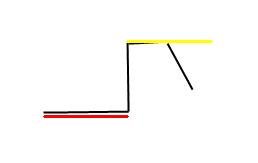

The thing is it's a bit of an awkward shape to make due to the curve in it.

What would people suggest is the best way to go about making a replacement? is it going to be a case of making each of the curved sections separately tacking them together and then seam welding them together. I can't see any easy way to bend it out of a single piece.

I'm not really afraid of having a bash myself but tbh I've not really done a lot of fabricating before but I'm pretty handy although I've not really got many metal work tools so I'm pretty much limited to an angle grinder and MiG welder

If anyone is interested in giving me a quote for making one then please feel free, i could send you the rotten one to copy. I know you could definitely shift a dozen or so easily if someone fancied doing a batch as it's a common failing point on the CTI's

anyway here's a few pic

I've got a section of my 205 convertible that has rotted through fairly spectacularly and needs replacing. The section clamps the back part of the hood to the car. The part is still available from Peugeot but at a ridiculous price. I was therefore hoping to either get one fabbed or repaired myself.

The thing is it's a bit of an awkward shape to make due to the curve in it.

What would people suggest is the best way to go about making a replacement? is it going to be a case of making each of the curved sections separately tacking them together and then seam welding them together. I can't see any easy way to bend it out of a single piece.

I'm not really afraid of having a bash myself but tbh I've not really done a lot of fabricating before but I'm pretty handy although I've not really got many metal work tools so I'm pretty much limited to an angle grinder and MiG welder

If anyone is interested in giving me a quote for making one then please feel free, i could send you the rotten one to copy. I know you could definitely shift a dozen or so easily if someone fancied doing a batch as it's a common failing point on the CTI's

anyway here's a few pic