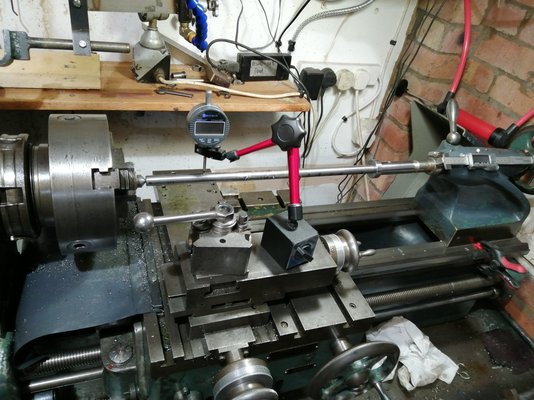

We recently bought a nice old Denbigh pillar drill, all works fine but there's too much runout. At the bottom, outside edge of the spindle (level 1 in the photo), it's about 0.08mm off. The inside of the spindle/ widest part of the internal morse taper (MT1) is 0.12mm off. By the time we get to the bottom of the chuck (level 2 in the photo) it's 0.24mm off. As you can imagine, a drill tip will be further off still.

Using engineers blue, we could see that the bottom end of the MT was a bit damaged and we cleaned it up with a file, which improved things (the figures above are after that improvement). We've checked the spindle along its length for straightness, and it is to within about 0.04mm.

Sooo, for some reason, the MT itself seems to be off. It is not concentric with the outside of the spindle. We also tried reaming it a little with a MT1 reamer, in case there was any further damage, but it's made no difference.

I can't think what else to do, apart from pay someone to recut the MT to MT2, aligned properly with the spindle. Or is there anything else we should be trying before going down that route? And any ideas what might have caused the MT to be misaligned with the spindle?

Thanks for any suggestions/ thoughts..

Chris

Using engineers blue, we could see that the bottom end of the MT was a bit damaged and we cleaned it up with a file, which improved things (the figures above are after that improvement). We've checked the spindle along its length for straightness, and it is to within about 0.04mm.

Sooo, for some reason, the MT itself seems to be off. It is not concentric with the outside of the spindle. We also tried reaming it a little with a MT1 reamer, in case there was any further damage, but it's made no difference.

I can't think what else to do, apart from pay someone to recut the MT to MT2, aligned properly with the spindle. Or is there anything else we should be trying before going down that route? And any ideas what might have caused the MT to be misaligned with the spindle?

Thanks for any suggestions/ thoughts..

Chris