JOEPRO

Member

- Messages

- 5,181

- Location

- UK

This roller door was fitted about 20 years ago. There has always been a 2 inch gap all along the top of its 4.5m width.

Having just installed a China diesel heater I wanted to give it a half chance and finally address this gap. It may also improve / reduce noise transfer in my built up area when working at weekends.

First problem was the render was all over the place and had to be ground back level. I also put a bevel on it to help reduce wear on the brush

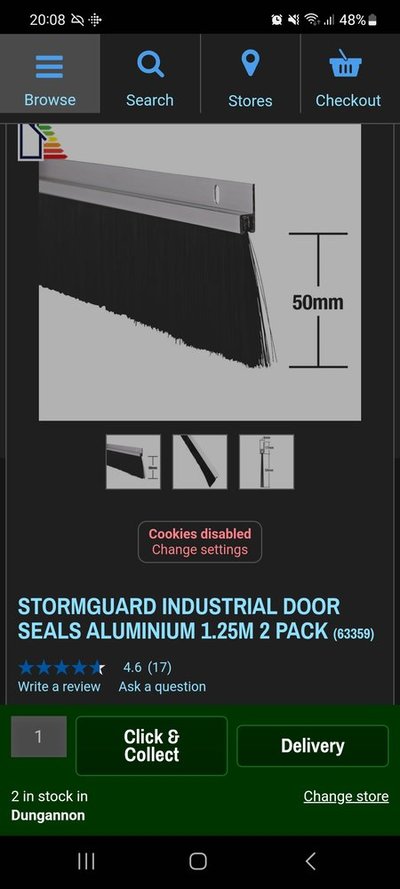

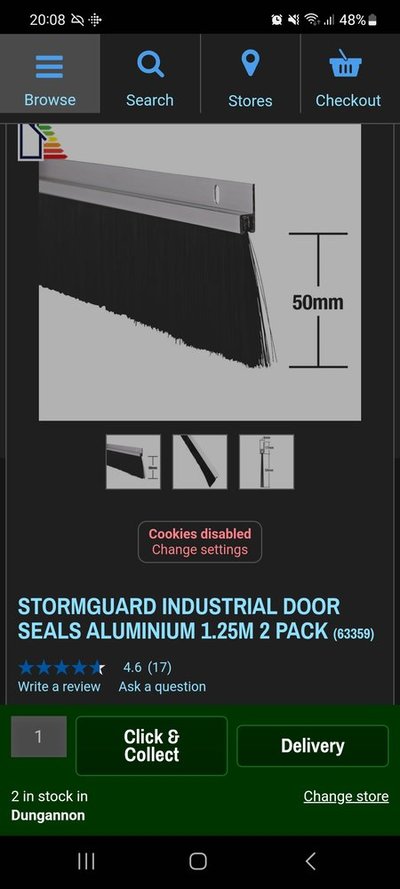

I used this stuff from Screwfix which was good value IMO

Trouble was I did not want to be drilling overhead on a RSJ beam 20x times. So I elected to add on mild steel tabs cut from a scrap galv strip

This meant I could then offer it up and arc weld to the beam. I don't arc weld often - but when I do it's terrible!! I'll blame the cheap welding rods.

I'll blame the cheap welding rods.

The cavity wall and beams will be insulated and closed in soon with a cembrit board. The welds are crap but holding it strong at least.

I placed the brush so it was just touching the door with no pressure when closed. I can open and close the door easily. The door does go back out a couple cm when raised so it's important to consider that.

Thought I would share this idea and how it worked out I think this is probably a common draught source in most garages

Having just installed a China diesel heater I wanted to give it a half chance and finally address this gap. It may also improve / reduce noise transfer in my built up area when working at weekends.

First problem was the render was all over the place and had to be ground back level. I also put a bevel on it to help reduce wear on the brush

I used this stuff from Screwfix which was good value IMO

Trouble was I did not want to be drilling overhead on a RSJ beam 20x times. So I elected to add on mild steel tabs cut from a scrap galv strip

This meant I could then offer it up and arc weld to the beam. I don't arc weld often - but when I do it's terrible!!

I'll blame the cheap welding rods.

I'll blame the cheap welding rods.

The cavity wall and beams will be insulated and closed in soon with a cembrit board. The welds are crap but holding it strong at least.

I placed the brush so it was just touching the door with no pressure when closed. I can open and close the door easily. The door does go back out a couple cm when raised so it's important to consider that.

Thought I would share this idea and how it worked out I think this is probably a common draught source in most garages