Well I've finished up the designing and I'm pretty happy with it! Should be plenty strong enough and uses what materials I already have/in scrap pile though do need to buy a couple bits.

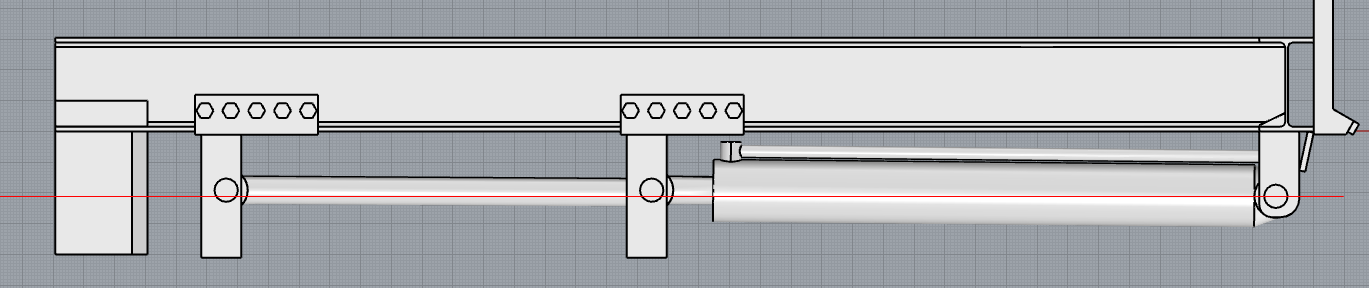

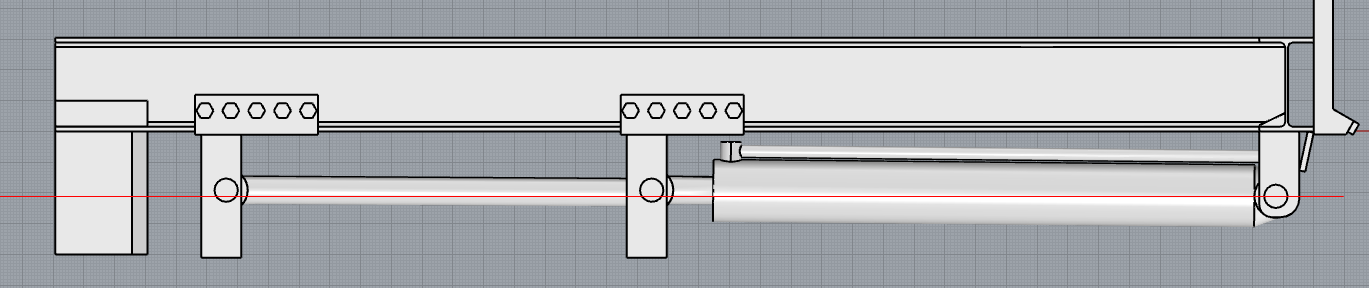

I'll be using this beast, 700mm stroke 45mm rod and ~85-90mm bore (though not completely sure) giving me easily 10t of splitting force.

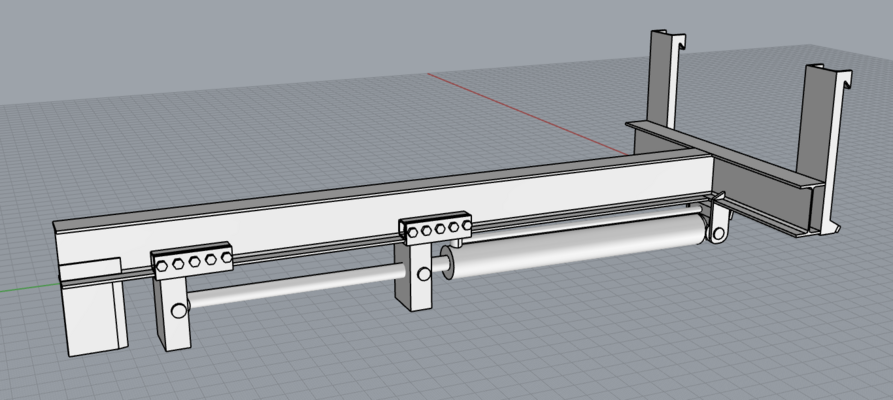

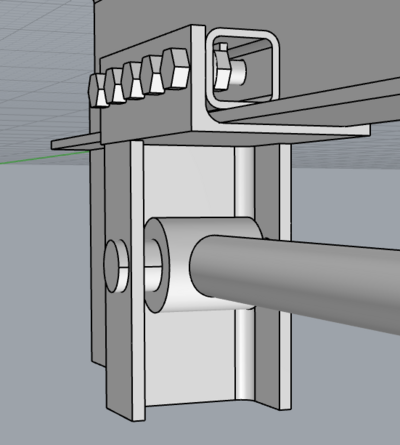

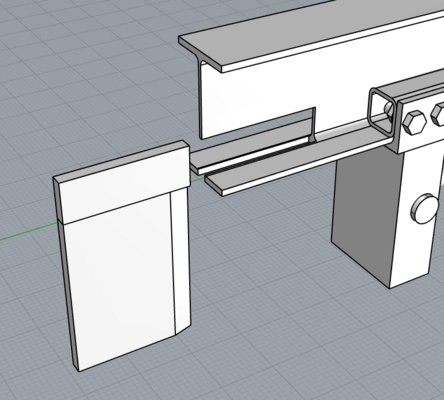

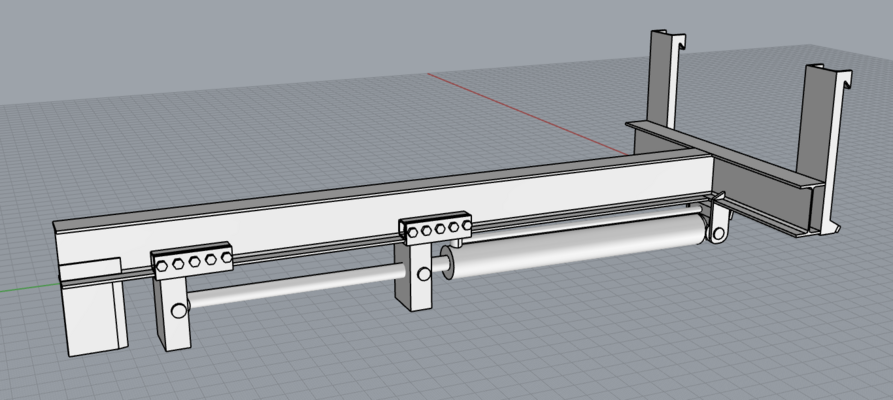

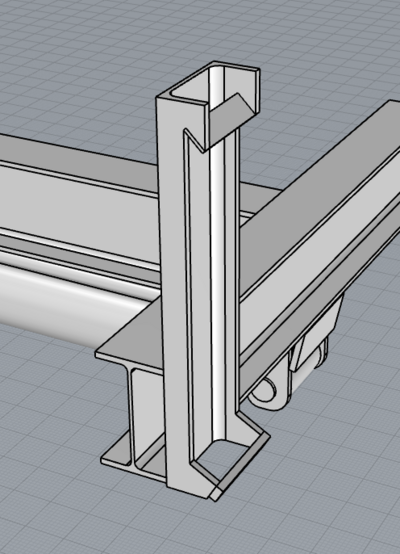

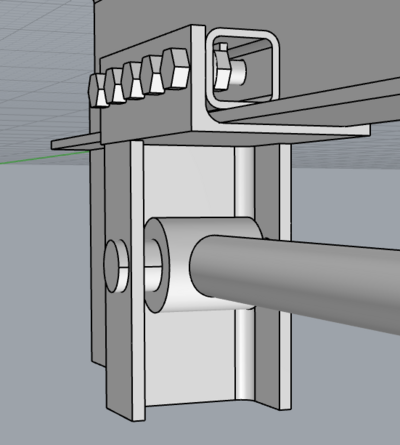

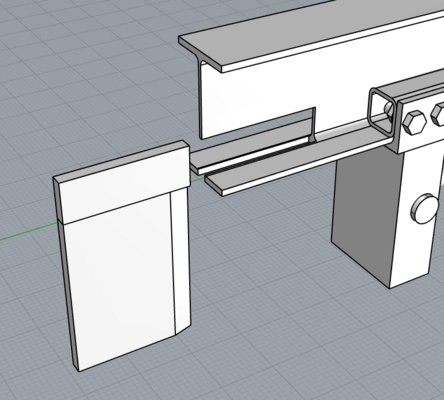

The assembly is primarily made from a 152x89 i beam and uses 125x65 u channel for the sliding push plate/skid steer attachment interface.

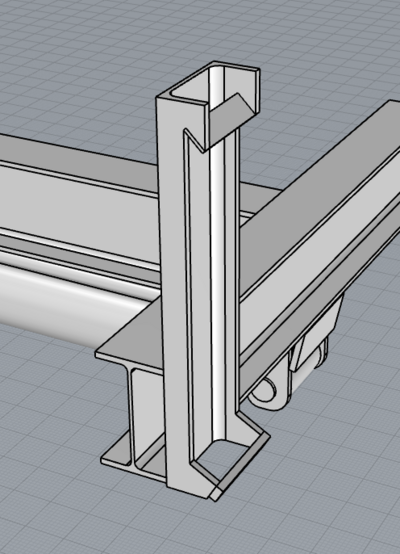

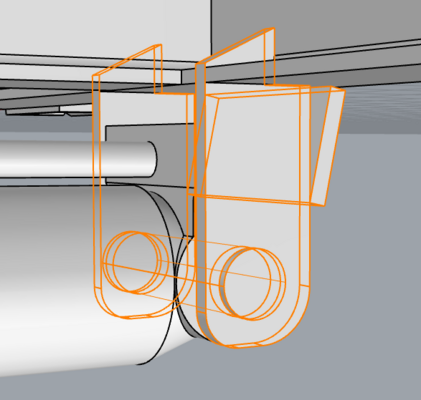

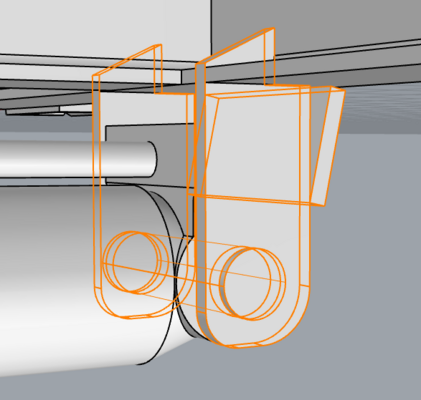

The cylinder is orientated with the retraction feed pipe/hose connection block between the cylinder and beam to protect it from damage and it's also set with 10mm vertical difference between the eyes so it's pushing into the beam slightly rather than parallel which should hopefully help and the rear mount is 65x10 flat bar slotted into the beam for maximum strength with a extra back piece just in case.

I'm rather pleased with the sliding push plate assembly, the i/u beams happen to fit perfectly together in such a way that 50x50x5mm box section drops in with 1mm clearance and 5x m16 bolts secure it thus restraining it from twisting/bending off and quick to build/fix if needed

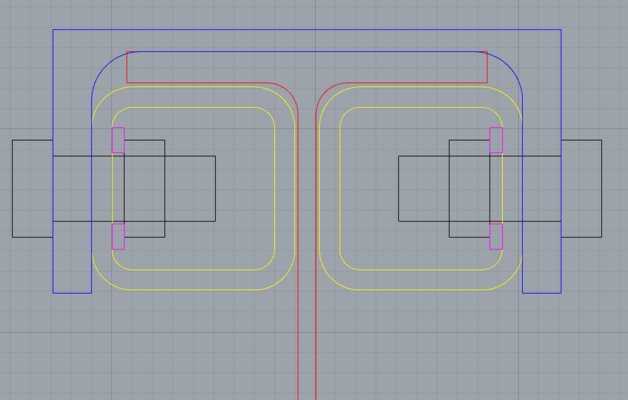

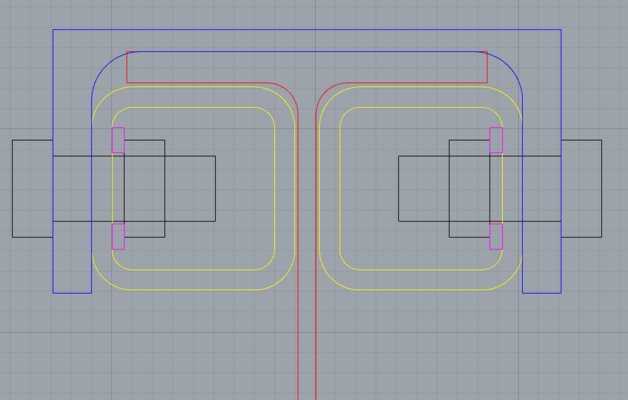

The splitter blade will be a 15mm thick plate, if I can find a short section of weld on cutting edge used on digger buckets (anyone got some?) then I'll use that otherwise it'll just be mild steel and I'll buy a pack of hardfacing rods being £14 for 1kg of sealey ones.

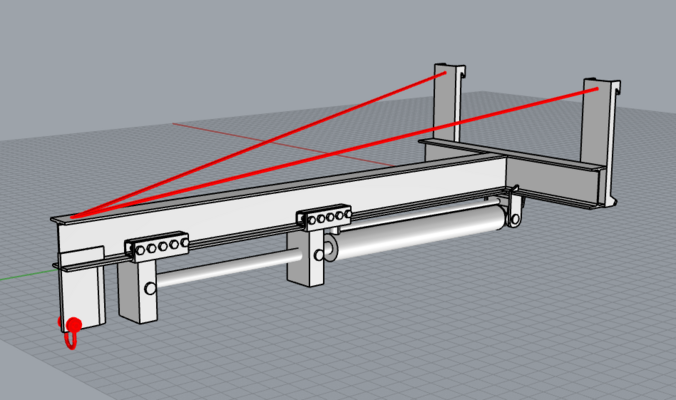

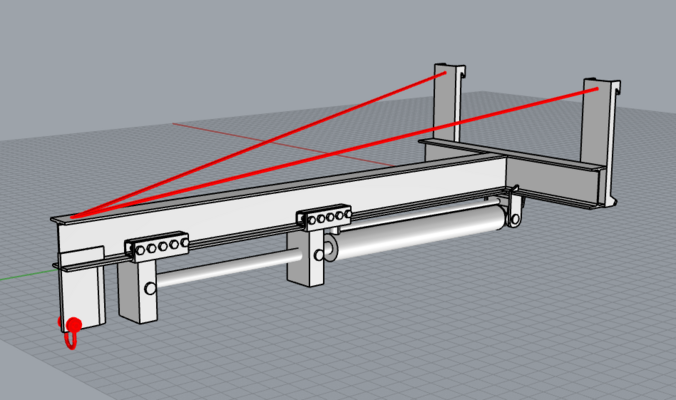

The best bit is I plan to mount some lengths of angle where the red lines are and drill a hole in the blade for a shackle thus giving me a 2m boom lift making it handy moving things where the forks don't currently reach!

I'll be using this beast, 700mm stroke 45mm rod and ~85-90mm bore (though not completely sure) giving me easily 10t of splitting force.

The assembly is primarily made from a 152x89 i beam and uses 125x65 u channel for the sliding push plate/skid steer attachment interface.

The cylinder is orientated with the retraction feed pipe/hose connection block between the cylinder and beam to protect it from damage and it's also set with 10mm vertical difference between the eyes so it's pushing into the beam slightly rather than parallel which should hopefully help and the rear mount is 65x10 flat bar slotted into the beam for maximum strength with a extra back piece just in case.

I'm rather pleased with the sliding push plate assembly, the i/u beams happen to fit perfectly together in such a way that 50x50x5mm box section drops in with 1mm clearance and 5x m16 bolts secure it thus restraining it from twisting/bending off and quick to build/fix if needed

The splitter blade will be a 15mm thick plate, if I can find a short section of weld on cutting edge used on digger buckets (anyone got some?) then I'll use that otherwise it'll just be mild steel and I'll buy a pack of hardfacing rods being £14 for 1kg of sealey ones.

The best bit is I plan to mount some lengths of angle where the red lines are and drill a hole in the blade for a shackle thus giving me a 2m boom lift making it handy moving things where the forks don't currently reach!