I have just got back to commissioning my CVA lathe.

The first job is to machine a backplate for a 160mm 3Jaw I picked up on fleabay a few years back.

The backplate is Warco's finest and steel rather than cast iron but all I need to do is machine the 125mm register and drill/tap 3 holes.

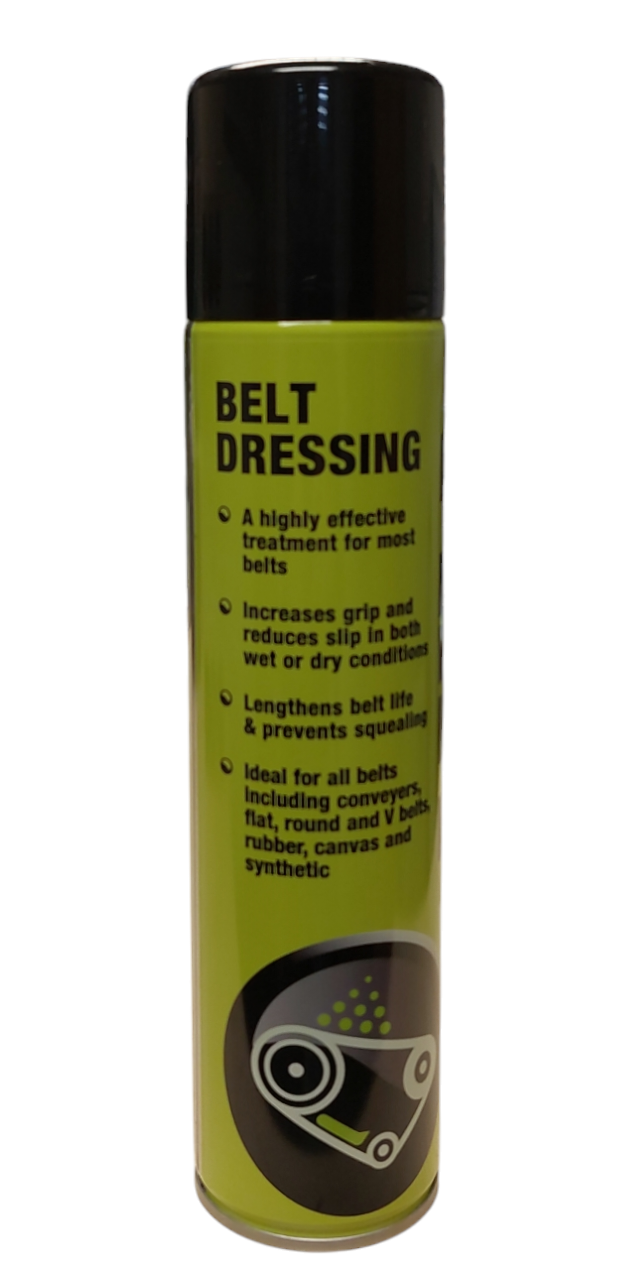

Easy, or so I thought, but I cannot take any serious cuts as the belt slips.

The belt (2.5 inches wide) is tight, feels supple although somewhat oily.

This isn't a great surprise as there was an oil leak from the gearbox onto the pulley when I got the machine.

So .... can I just wash it in water with a degreaser or is there something better for leather belts.

Thanks

The first job is to machine a backplate for a 160mm 3Jaw I picked up on fleabay a few years back.

The backplate is Warco's finest and steel rather than cast iron but all I need to do is machine the 125mm register and drill/tap 3 holes.

Easy, or so I thought, but I cannot take any serious cuts as the belt slips.

The belt (2.5 inches wide) is tight, feels supple although somewhat oily.

This isn't a great surprise as there was an oil leak from the gearbox onto the pulley when I got the machine.

So .... can I just wash it in water with a degreaser or is there something better for leather belts.

Thanks