Pete.

Member

- Messages

- 14,705

- Location

- Kent, UK

One of the hydraulic packs at work packed up this week. New parts are a week away so I said I'd repair this one in the meantime.

This is a flow and pressure control valve. It gets constantly adjusted and this has caused the thread to wear in one spot.

So if you wind the control right out it slips on the thread and you can't get any pressure on the machine. I found a bit of 303 stainless and re-made that part.

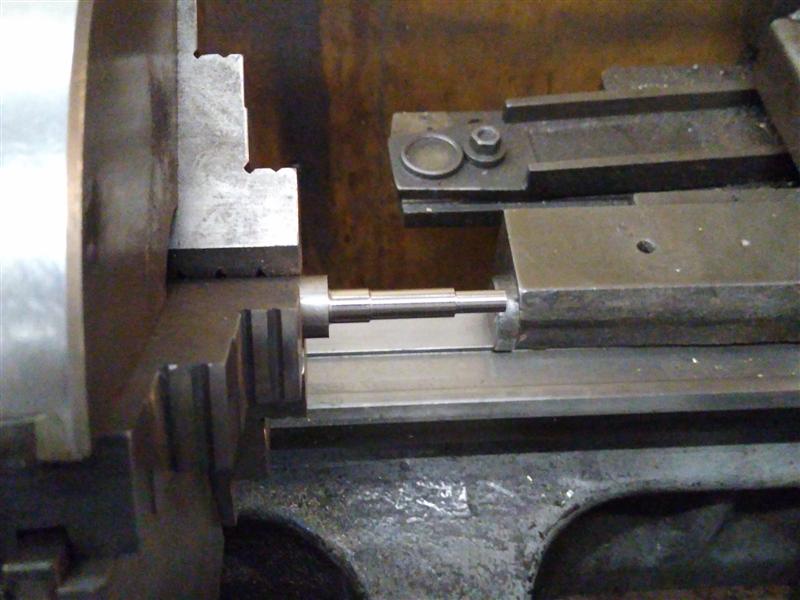

First turn the three diameters on my lathe.

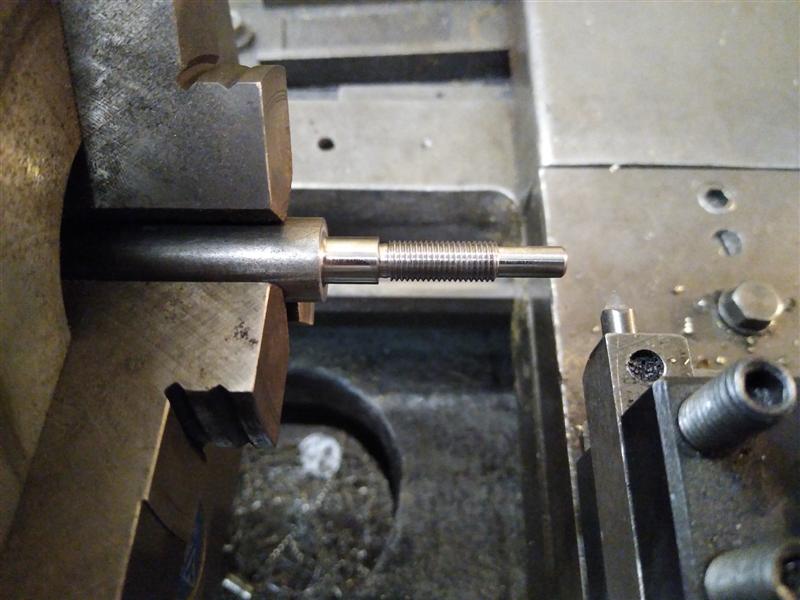

Then thread the middle section 8mm x 1.0 pitch. I roughed it out with the tool shown here and finished it with a die afterwards. Never thought I'd ever use that die since I got it but now I have

After that I turned the groove for the o-ring and parted it off but no photo of that because it was badly blurred. Then I drilled the hole for the control knob screw.

New part next to the old one.

Ready for re-assembly. All in all took me about 2.5 hrs.

If you think it's a bit odd to be machining around midnight then you'd be right - except I am working 3-11pm right now so I don't normally get home till around midnight. Tonight we got done early so really I've been working on company time. Only seem fair since it is a bit for their machine

This is a flow and pressure control valve. It gets constantly adjusted and this has caused the thread to wear in one spot.

So if you wind the control right out it slips on the thread and you can't get any pressure on the machine. I found a bit of 303 stainless and re-made that part.

First turn the three diameters on my lathe.

Then thread the middle section 8mm x 1.0 pitch. I roughed it out with the tool shown here and finished it with a die afterwards. Never thought I'd ever use that die since I got it but now I have

After that I turned the groove for the o-ring and parted it off but no photo of that because it was badly blurred. Then I drilled the hole for the control knob screw.

New part next to the old one.

Ready for re-assembly. All in all took me about 2.5 hrs.

If you think it's a bit odd to be machining around midnight then you'd be right - except I am working 3-11pm right now so I don't normally get home till around midnight. Tonight we got done early so really I've been working on company time. Only seem fair since it is a bit for their machine