Munkul

Jack of some trades, Master of none

- Messages

- 7,696

- Location

- Cumbria

Some tests I did last night, to satisfy my own curiosity.

I ran three steel fillet plates, 6mm thick, all in the flat 2F position, no cleaning beforehand. Afterwards cut, polished with 120G then 320G. Etched with S/S passivating fluid and a few seconds of heat w/ blowtorch.

- One in short-circuit, one in synergic pulse, one in spray.

93/5/2 Ar/CO2/O2 shielding gas, 1mm solid G3Si1 wire, on Miller XMT 304, Optima pulser, S64 wire feeder.

First, I ran 380IPM, 22 volts short arc, it was in the transitional globular transfer so I ramped up to 410IPM, 24V on the other side. (not a fair test since it was hot, but as you can see, not much difference). Cursive 'e's.

Secondly, I ran the pulser on program 9, adaptive, 410IPM, arc length 52, giving a slight crackle to the pulsed arc. Ever so slight manipulaton, very small 'e's.

I wanted to try a bend test on this, since I've had and read mixed results with older pulse programs on steel. It bended just fine:

Lastly, I ran a spray setting that felt good to me - 28V and 480IPM, again a slight crackle but I wanted a good hot weld. Barely any manipulation - just a slight move-pause.

I ran three steel fillet plates, 6mm thick, all in the flat 2F position, no cleaning beforehand. Afterwards cut, polished with 120G then 320G. Etched with S/S passivating fluid and a few seconds of heat w/ blowtorch.

- One in short-circuit, one in synergic pulse, one in spray.

93/5/2 Ar/CO2/O2 shielding gas, 1mm solid G3Si1 wire, on Miller XMT 304, Optima pulser, S64 wire feeder.

First, I ran 380IPM, 22 volts short arc, it was in the transitional globular transfer so I ramped up to 410IPM, 24V on the other side. (not a fair test since it was hot, but as you can see, not much difference). Cursive 'e's.

Secondly, I ran the pulser on program 9, adaptive, 410IPM, arc length 52, giving a slight crackle to the pulsed arc. Ever so slight manipulaton, very small 'e's.

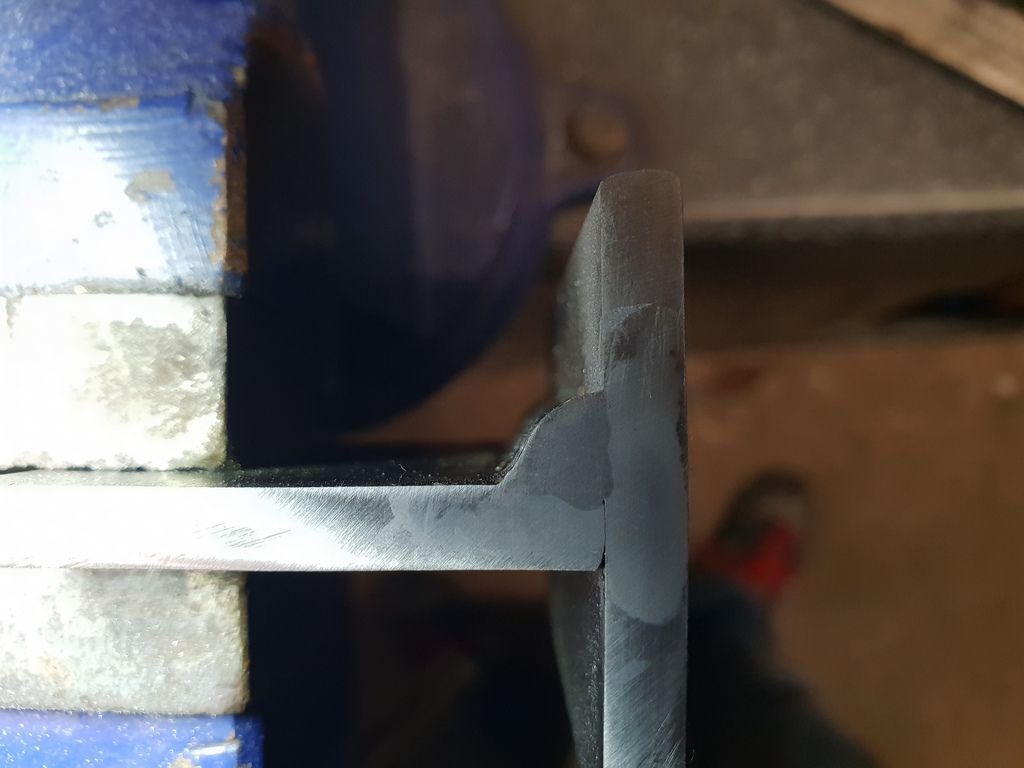

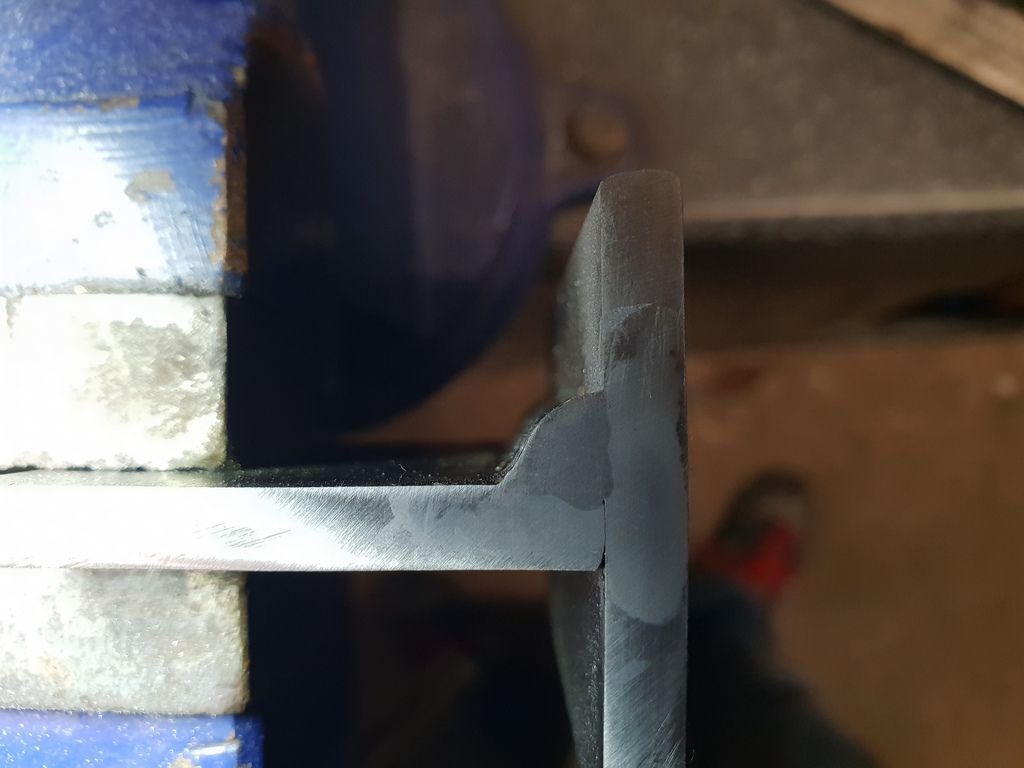

I wanted to try a bend test on this, since I've had and read mixed results with older pulse programs on steel. It bended just fine:

Lastly, I ran a spray setting that felt good to me - 28V and 480IPM, again a slight crackle but I wanted a good hot weld. Barely any manipulation - just a slight move-pause.