Hood

I am obsessed.

- Messages

- 17,613

- Location

- Carnoustie, Scotland

Finally got enough done to the CNC table to test out the plasma and I have had quite a few problems.

One however is more worrying than the rest as it is the one I am not sure how to fix.

What the problem is, the torch is at pierce height, the pilot starts and immediately it transitions to the cutting arc but then sometimes it kind of softens for a bit then comes back to life.

I have looked around and I am thinking it may be what is termed "Double Arcing" but I am not 100% sure of that.

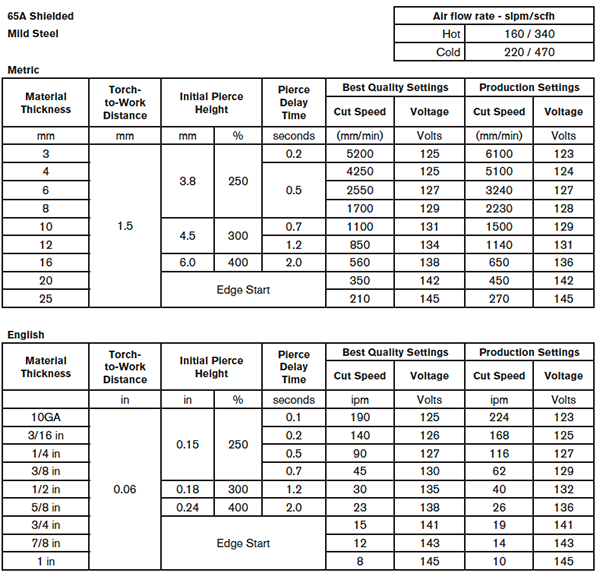

I have tried quite a few things, increasing and decreasing the air pressure, increasing,decreasing the pierce height, increasing/decreasing the pierce time but none have made much difference.

I have a couple of other things to try when I next get time, I am going to reduce the current slightly and the other thing I will try is have a slow move whilst piercing.

Anyway here is a video of the issue, hopefully you can see what I am meaning.

One however is more worrying than the rest as it is the one I am not sure how to fix.

What the problem is, the torch is at pierce height, the pilot starts and immediately it transitions to the cutting arc but then sometimes it kind of softens for a bit then comes back to life.

I have looked around and I am thinking it may be what is termed "Double Arcing" but I am not 100% sure of that.

I have tried quite a few things, increasing and decreasing the air pressure, increasing,decreasing the pierce height, increasing/decreasing the pierce time but none have made much difference.

I have a couple of other things to try when I next get time, I am going to reduce the current slightly and the other thing I will try is have a slow move whilst piercing.

Anyway here is a video of the issue, hopefully you can see what I am meaning.

.

.