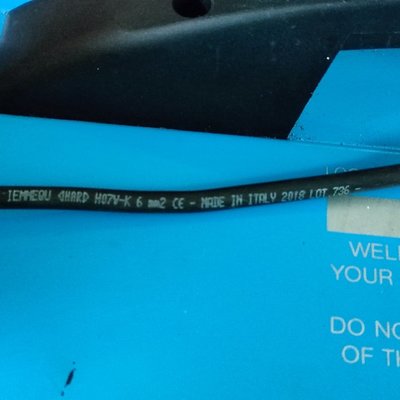

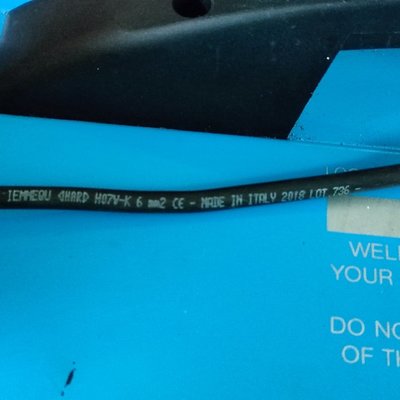

Good evening all. I've had the Pro 90 for about 4 years and it's not been bad at all for thin car bodywork managed to repair a front cross member on my old nissan. The earth clamp on it is pretty feeble and the cable is only 6mm( minimum spec) . Had a look around and a cable with a dinse connector looks a good option? The cable is not very long either. As far as I can see I would need a dinse socket to go on the front of the case where the current earth goes through the hole and inside the welder there's a butt type crimp connector( 2nd picture)so I would need another piece of 16mm cable to go between the crimp connector and the back of the dinse socket with a lug on it. I've got a neighbour who's an electrician so should be able to get a new cable crimped. I was thinking a 16mm cable and should be ok for this welder as it's only 90amps.Hopefully it will help improve the welding lol. Have a sill to weld up on a nissan soon found a small hole where someone put a patch panel on before have to get it done soon while the weather's still warm! Any tips or words of wisdom would be appreciated.

Thanks marco

Thanks marco

There have been a few threads in the past if you use the search at the top of the page.

There have been a few threads in the past if you use the search at the top of the page.